3 Reasons Why Effluent Treatment Is Important

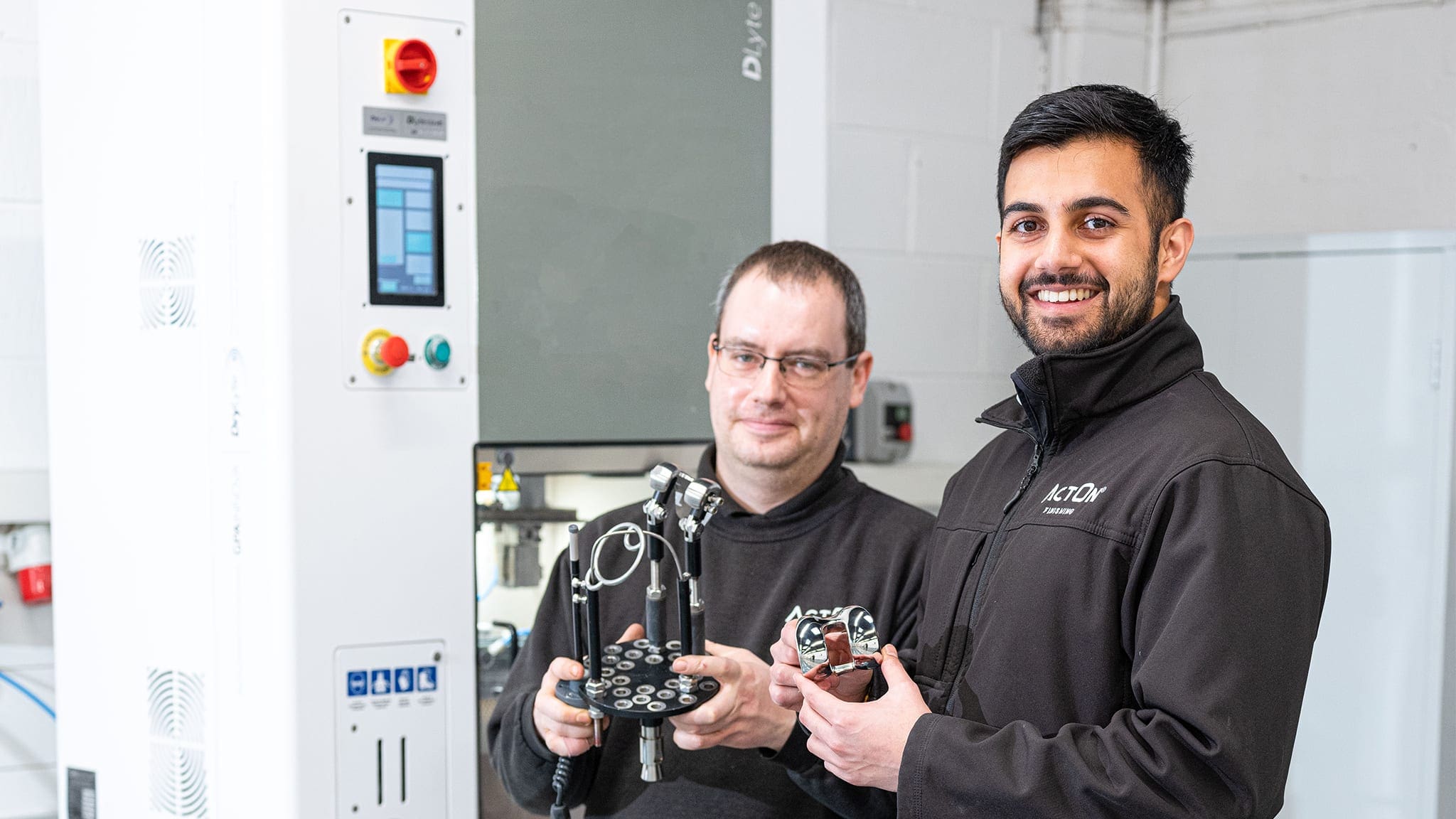

When undertaking wet mass finishing, it generates a discharge of the processing liquid, made up of the metal fines, abrasives, compound and in some instances oil due to the condition of the parts. There are various ways you can dispose of this liquid, but at ActOn Finishing we’ve always recommended investing in a suitable effluent… Read more »

Read more