-

-

-

- About

- Industries

-

Sub-Contracting

-

- Consumables

-

Cleaning

-

- All Ultrasonic Machines

- TT Standard Ultrasonic Series

- LT Pro Laboratory Ultrasonic Cleaning Machines

- MOT Automotive Ultrasonic Cleaning Machines

- One Tank Industrial Ultrasonic Cleaning Equipment

- Manual Multistage Ultrasonic Cleaning Equipment

- Multistage Automatic Ultrasonic Cleaning Machine

- Ultrasonic Generators

- Ultrasonic Cleaner Solution

-

-

Blasting & Peening

-

- All Shot Blasting Machines

- Powertrack Junior Portable Blast System

- Powertrack Portable Blast System

- ActOn Mobile Shot Blasting Room

- ECO Shot Blasting Machines

- Premium DI Suction Blasting Machines

- Premium DP Pressure Blasting Cabinets

- AWB Wet Blasting Cabinet

- Premium NP Wet Blasting Cabinets

- Automated Wet Blasting Machine

- NF Sandblasting Cabinets

- DLyte eBlast – Electro Shot Blaster

- AM Shot Peening and Blasting Series

- Automated Shot Blasting Equipment

- All Wheel Blasting Machines

- Spinner Hanger Blast Machine

- Tumble Rubber Belt Shot Blasting Machine

- Tumble Steel Belt Shot Blasting Machine

- Wire Mesh Belt Shot Blasting Machine

- Continuous Feed Overhead Rail Blasting Machine

- Roller Conveyor Blast Machine

- Continuous Feed Tube & Bar Blast Cleaning Machine

- Rotary Table Shot Blasting Machine

- Tunnel Concrete Shot Blast Machine

-

-

Surface Finishing

-

-

Surface Finishing

- All Mass Finishing Machines

- Vibratory Bowl Machines

- Vibratory Trough Machines

- Dual Finishing Machines

- Dryers

- Centrifugal High Energy Machines

- Disc Finishing Machines

- LE30 Rotary Barrel Machine

- Wheel Polishing Machine

- Automation for Mass Finishing

- Mass Finishing Accessories

- All Vibratory Machines

- Vibratory Dual Machines

- Vibratory Consumables

- Vibratory Bowl Machines

- Vibratory Trough Machines

- Dlyte Technology

- Waste Water Treatment

- REFURBISHED MACHINES

-

Blasting & Peening

- All Shot Blasting Machines

- Powertrack Junior Portable Blast System

- Powertrack Portable Blast System

- ActOn Mobile Shot Blasting Room

- ECO Shot Blasting Machines

- Premium DI Suction Blasting Machines

- Premium DP Pressure Blasting Cabinets

- AWB Wet Blasting Cabinet

- Premium NP Wet Blasting Cabinets

- Automated Wet Blasting Machine

- NF Sandblasting Cabinets

- DLyte eBlast – Electro Shot Blaster

- AM Shot Peening and Blasting Series

- Automated Shot Blasting Equipment

- All Wheel Blasting Machines

- Spinner Hanger Blast Machine

- Tumble Rubber Belt Shot Blasting Machine

- Tumble Steel Belt Shot Blasting Machine

- Wire Mesh Belt Shot Blasting Machine

- Continuous Feed Overhead Rail Blasting Machine

- Roller Conveyor Blast Machine

- Continuous Feed Tube & Bar Blast Cleaning Machine

- Rotary Table Shot Blasting Machine

- Tunnel Concrete Shot Blast Machine

- Refurbished Machines

-

Cleaning

- All Ultrasonic Machines

- TT Standard Ultrasonic Series

- LT Pro Laboratory Ultrasonic Cleaning Machines

- MOT Automotive Ultrasonic Cleaning Machines

- One Tank Industrial Ultrasonic Cleaning Equipment

- Manual Multistage Ultrasonic Cleaning Equipment

- Multistage Automatic Ultrasonic Cleaning Machine

- Ultrasonic Generators

- Ultrasonic Cleaner Solution

- Vibratory Finishing Machines

- Consumables

- Sub-Contracting

- Industries

- About

- Free Trial

- Contact us

ActOn AM Shot Peening & Blasting Series

Both powder-based metal and polymer additive manufactured parts require post-processing to remove the residue left from the 3D printing process and achieve a smooth finish. At ActOn we offer the AM Shot Peening & Shot Blasting cabinets for finishing metal and polymer 3D printed parts. The AM series include:

– the AM DI Blasting cabinets for de-powdering and smooth finishing metal 3D printed parts;

– the AM Blasting Clean technology for the de-powdering 3D printed polymer parts;

– and the AM Blasting Smooth series which is perfect for achieving a homogenous & smooth surface finishing on additive manufactured polymer components.

AM Blasting for Polymer 3D Printed Parts

This range of machines includes The Clean Series and the Smooth Series. The AM Blasting Clean Series includes 4 models: Excel, Solid, Smart and Samba. These machines are designed to de-powder the 3D printed parts using a glass bead media. De-powdering with this kind of abrasive media has the advantage of achieving a deep de-powdering of the product. You will reach into corners where a round shot will not get.

Like the Clean technology, the AM Blasting Smooth Series includes 4 models: Excel, Solid, Smart and Samba. These machines are designed for shot peening the 3D printed polymer parts using a round abrasive media. Further to this stage, component’s surface is homogeneous, smooth and porosity is reduced. The shot peening treatment in particular improves the result of the subsequent colouring process.

DOWNLOAD BROCHURE

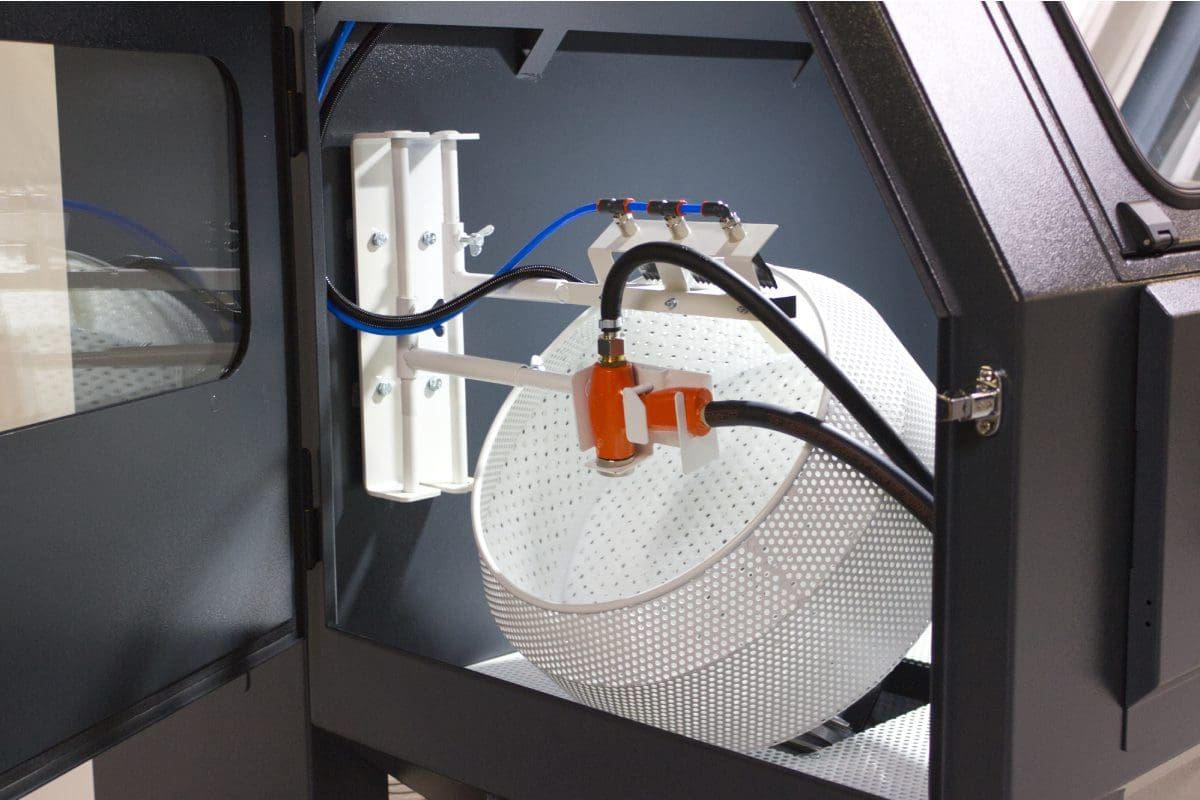

AM DI Blasting Cabinets

The AM DI de-powdering system is developed for manually cleaning of powder bed printed parts. Some of the main key features of this cabinet include:

- Suitable for blasting off individual or large parts.

- Manual blasting of 3D printed parts up to a load of max. 350 kg.

- Equipped with a cyclone to remove dust and powder from the blast media.

- ATEX certified for processes class II 3/-D T125˚

- Also suitable for shot peening, without any modifications.

- 2 side doors.

- Safety on doors.

- LED lighting

Technical Specifications

For further technical specifications on our AM Shot Peening and Blasting Series please download our brochure.

DOWNLOAD BROCHURE