-

-

-

- About

- Industries

-

Sub-Contracting

-

- Consumables

-

Cleaning

-

- All Ultrasonic Machines

- TT Standard Ultrasonic Series

- LT Pro Laboratory Ultrasonic Cleaning Machines

- MOT Automotive Ultrasonic Cleaning Machines

- One Tank Industrial Ultrasonic Cleaning Equipment

- Manual Multistage Ultrasonic Cleaning Equipment

- Multistage Automatic Ultrasonic Cleaning Machine

- Ultrasonic Generators

- Ultrasonic Cleaner Solution

-

-

Blasting & Peening

-

- All Shot Blasting Machines

- Powertrack Junior Portable Blast System

- Powertrack Portable Blast System

- ActOn Mobile Shot Blasting Room

- ECO Shot Blasting Machines

- Premium DI Suction Blasting Machines

- Premium DP Pressure Blasting Cabinets

- AWB Wet Blasting Cabinet

- Premium NP Wet Blasting Cabinets

- Automated Wet Blasting Machine

- NF Sandblasting Cabinets

- DLyte eBlast – Electro Shot Blaster

- AM Shot Peening and Blasting Series

- Automated Shot Blasting Equipment

- All Wheel Blasting Machines

- Spinner Hanger Blast Machine

- Tumble Rubber Belt Shot Blasting Machine

- Tumble Steel Belt Shot Blasting Machine

- Wire Mesh Belt Shot Blasting Machine

- Continuous Feed Overhead Rail Blasting Machine

- Roller Conveyor Blast Machine

- Continuous Feed Tube & Bar Blast Cleaning Machine

- Rotary Table Shot Blasting Machine

- Tunnel Concrete Shot Blast Machine

-

-

Surface Finishing

-

-

Surface Finishing

- All Mass Finishing Machines

- Vibratory Bowl Machines

- Vibratory Trough Machines

- Dual Finishing Machines

- Dryers

- Centrifugal High Energy Machines

- Disc Finishing Machines

- LE30 Rotary Barrel Machine

- Wheel Polishing Machine

- Automation for Mass Finishing

- Mass Finishing Accessories

- All Vibratory Machines

- Vibratory Dual Machines

- Vibratory Consumables

- Vibratory Bowl Machines

- Vibratory Trough Machines

- Dlyte Technology

- Waste Water Treatment

- REFURBISHED MACHINES

-

Blasting & Peening

- All Shot Blasting Machines

- Powertrack Junior Portable Blast System

- Powertrack Portable Blast System

- ActOn Mobile Shot Blasting Room

- ECO Shot Blasting Machines

- Premium DI Suction Blasting Machines

- Premium DP Pressure Blasting Cabinets

- AWB Wet Blasting Cabinet

- Premium NP Wet Blasting Cabinets

- Automated Wet Blasting Machine

- NF Sandblasting Cabinets

- DLyte eBlast – Electro Shot Blaster

- AM Shot Peening and Blasting Series

- Automated Shot Blasting Equipment

- All Wheel Blasting Machines

- Spinner Hanger Blast Machine

- Tumble Rubber Belt Shot Blasting Machine

- Tumble Steel Belt Shot Blasting Machine

- Wire Mesh Belt Shot Blasting Machine

- Continuous Feed Overhead Rail Blasting Machine

- Roller Conveyor Blast Machine

- Continuous Feed Tube & Bar Blast Cleaning Machine

- Rotary Table Shot Blasting Machine

- Tunnel Concrete Shot Blast Machine

- Refurbished Machines

-

Cleaning

- All Ultrasonic Machines

- TT Standard Ultrasonic Series

- LT Pro Laboratory Ultrasonic Cleaning Machines

- MOT Automotive Ultrasonic Cleaning Machines

- One Tank Industrial Ultrasonic Cleaning Equipment

- Manual Multistage Ultrasonic Cleaning Equipment

- Multistage Automatic Ultrasonic Cleaning Machine

- Ultrasonic Generators

- Ultrasonic Cleaner Solution

- Vibratory Finishing Machines

- Consumables

- Sub-Contracting

- Industries

- About

- Free Trial

- Contact us

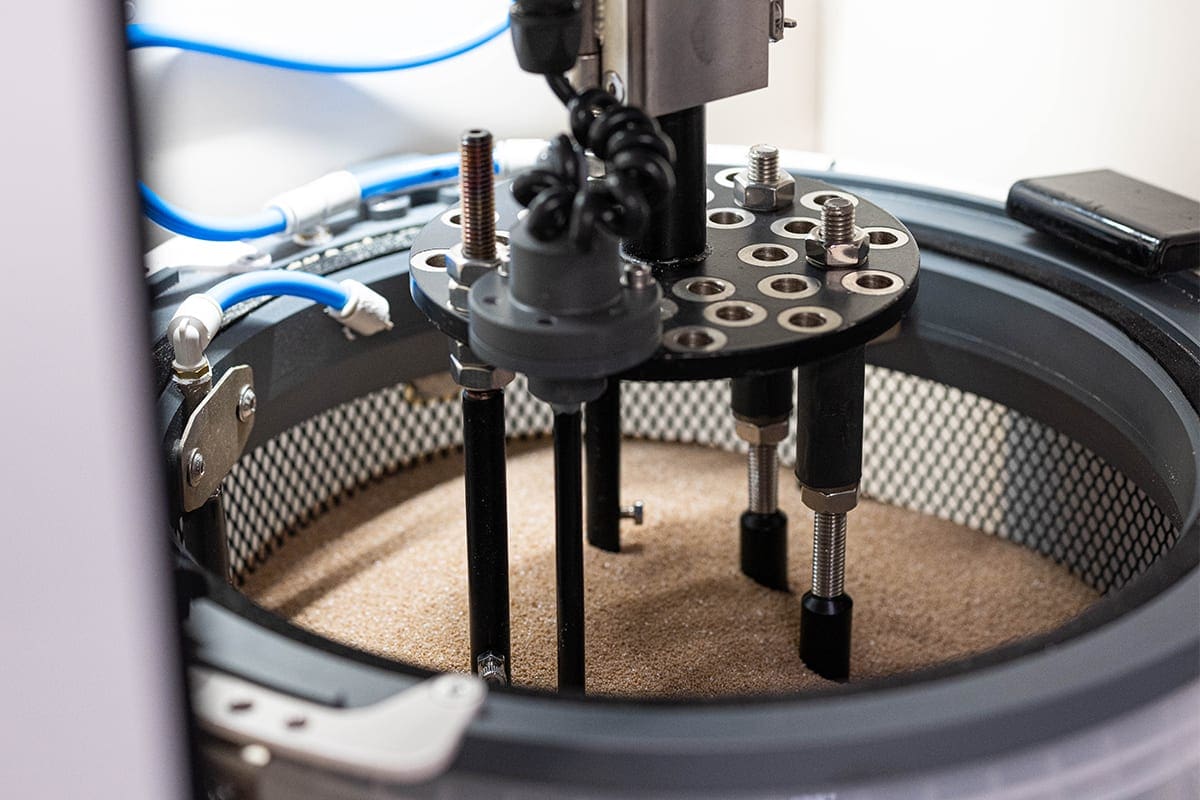

DLyte Technology

The DLyte polishing machine achieves high quality finishing for machined, sintered and casting parts, obtaining a mirror finish result. The polishing action reaches every corner of the piece, so it can process inner cavities which cannot be accessed mechanically.

Unlike traditional polishing, DLyte® Technology differentiates itself by its ability to preserve the initial shapes, even the cutting edges, and penetrate into all dead zones. It creates homogeneous polishing across the surface, without grinding patterns and has the ability to process complex geometries without leaving micro-scratches on the surface.

Key Features and Benefits

- Maximum size of part to be processed: 180 Ø x 80mm.

- Programmable cycle time.

- Quick and easy change of media.

- Anti-vibratory support with wheels for easy handling.

- Low maintenance costs.

- No dust emission.

- CE certificate.

- Achieves homogeneous results across the surface and eliminates any micro-scratches.

- Respects the tolerances and preserves the initial shape.

- Achieves an Ra under 0,09 micrometres.

- Avoids generating grinding texture patterns.

- Improved resistance to part wear and fracture resistance.

- No contamination and no traces of hydrogen on the surface.

- Controlled costs and predictable lead times.

All the features from a DLyte machine, available in an ultra-compact system. This equipment has been designed to allow any manufacturer, workshop, workroom and SMEs, who would require a cost-effective solution for metal surface finishing, to use the dry electropolishing technology. Here are just a few key features and benefits:

- Up to 10 times faster than traditional equipment.

- Consistent surface finishing results every time.

- Plug-and-play system. It operates with a standard household electrical plug.

- Affordable finishing solution.

- Easy to maintain.

- Achieves an Ra under 0,01 micrometers.

- CE certificate.

Technical Specifications

For further technical specifications on the DLyte Polishing Machines, please download our brochure.

DOWNLOAD BROCHURE

DLyte Polishing Machine Applications

DLyte allows polishing of Castings, Sintered and CNC parts and is designed to polish components manufactured out of Cobalt Chrome, Stainless Steel, Carbon Steel, Nickel Alloys, Copper Alloys, Titanium and Nitinol.

Here are just a handful of parts that we can help to perfect:

- HEALTHCARE – Implants, Instruments, Prosthetic Components, Hearing Aid, Needle

- INDUSTRIAL – Moulds, Dies, Industrial Precision Parts, Cutting Tools, Engine Parts, Watch Case

- AEROSPACE – Blisks, Stators, Blades, Manifolds, Brackets, Guide Vanes, Bearings, Gears

- AUTOMOTIVE – Impellers, Shafts, Gears, Bearings, Joint Balls, Fuel Injectors, Brake Parts, Luxury Inserts