So, you’ve heard of a dry electropolishing machine, and want to understand what it is, the process and its features? Join us as we discuss everything there is to know about dry electropolishing and its various benefits in our latest blog…

What is dry electropolishing?

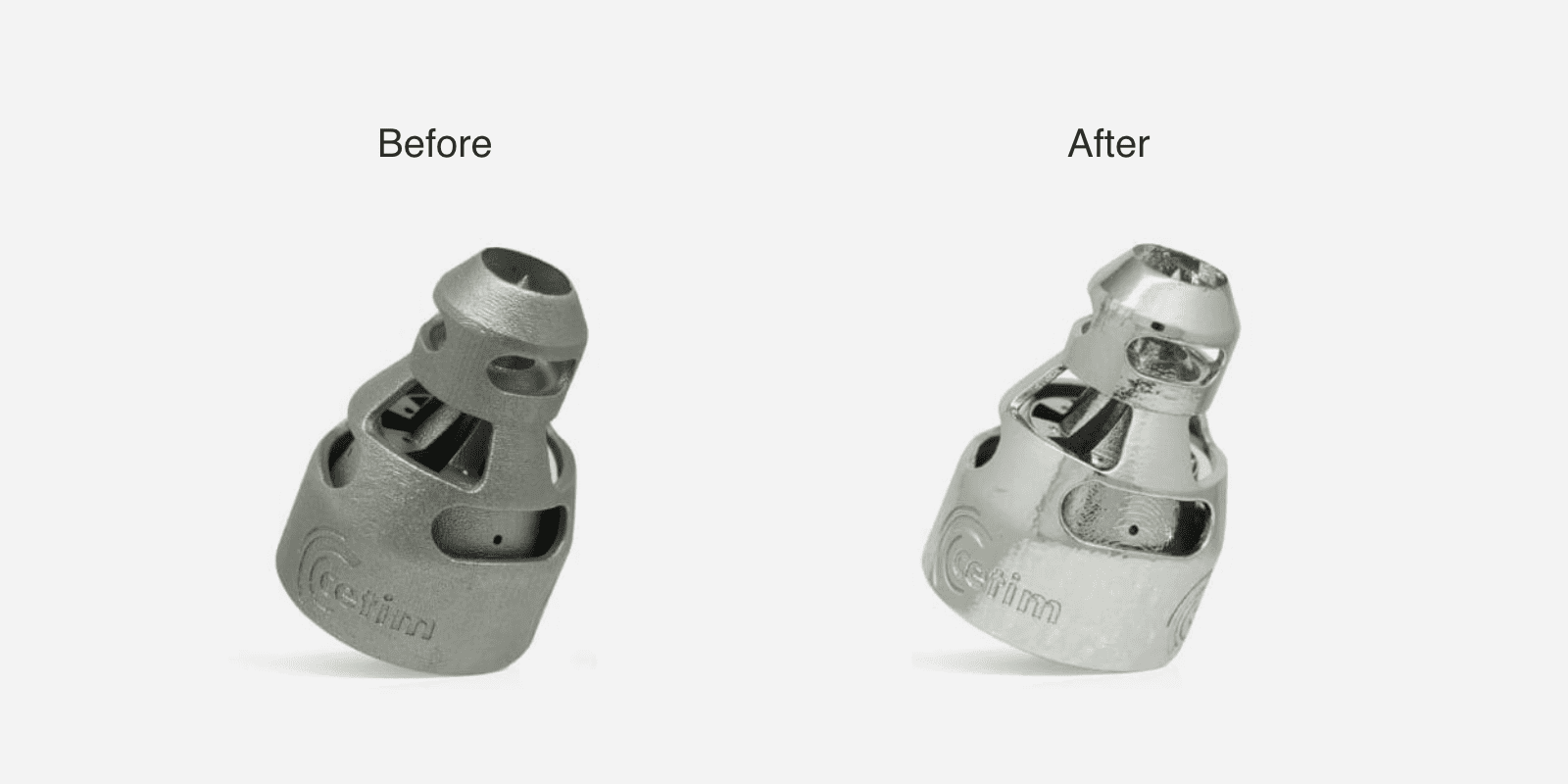

Put simply, dry electropolishing is a relatively new surface finishing process made for polishing metal parts. Dry electropolishing machines remove peaks of roughness from a metal surface, without affecting the shape or overall dimensions of the metal part.

What finishing applications can dry electropolishing achieve?

This process is commonly used to enhance the corrosion resistance, achieve superior finishing results.

What are the benefits of dry electropolishing?

- Precision surface finishing: especially for components with strict tolerances which require an improved aesthetic look, lifespan and resistance to corrosion.

- Smoothing: to remove grind lines or scratches, or for levelling the surface of the component.

- Mirror finish: a finish often asked by industries such as fashion, food, pharma, medical, aerospace and luxury, for being visually appealing and for the lack of surface scratches.

- Deburring: perfect for removing burrs from fragile parts, without damaging it.

- Rounding: especially for tools which need a cutting edge geometry to improve lifespan, performance and surface quality.

- Corrosion resistance: dry electropolishing can remove the lair of corrosion from metals such as titanium, cobalt chrome, copper, aluminium or stainless steel.

- Polishing inner cavities and channels: a cost effective way to process parts with complex shapes, cavities and channels as the media can reach of the corner of the component.

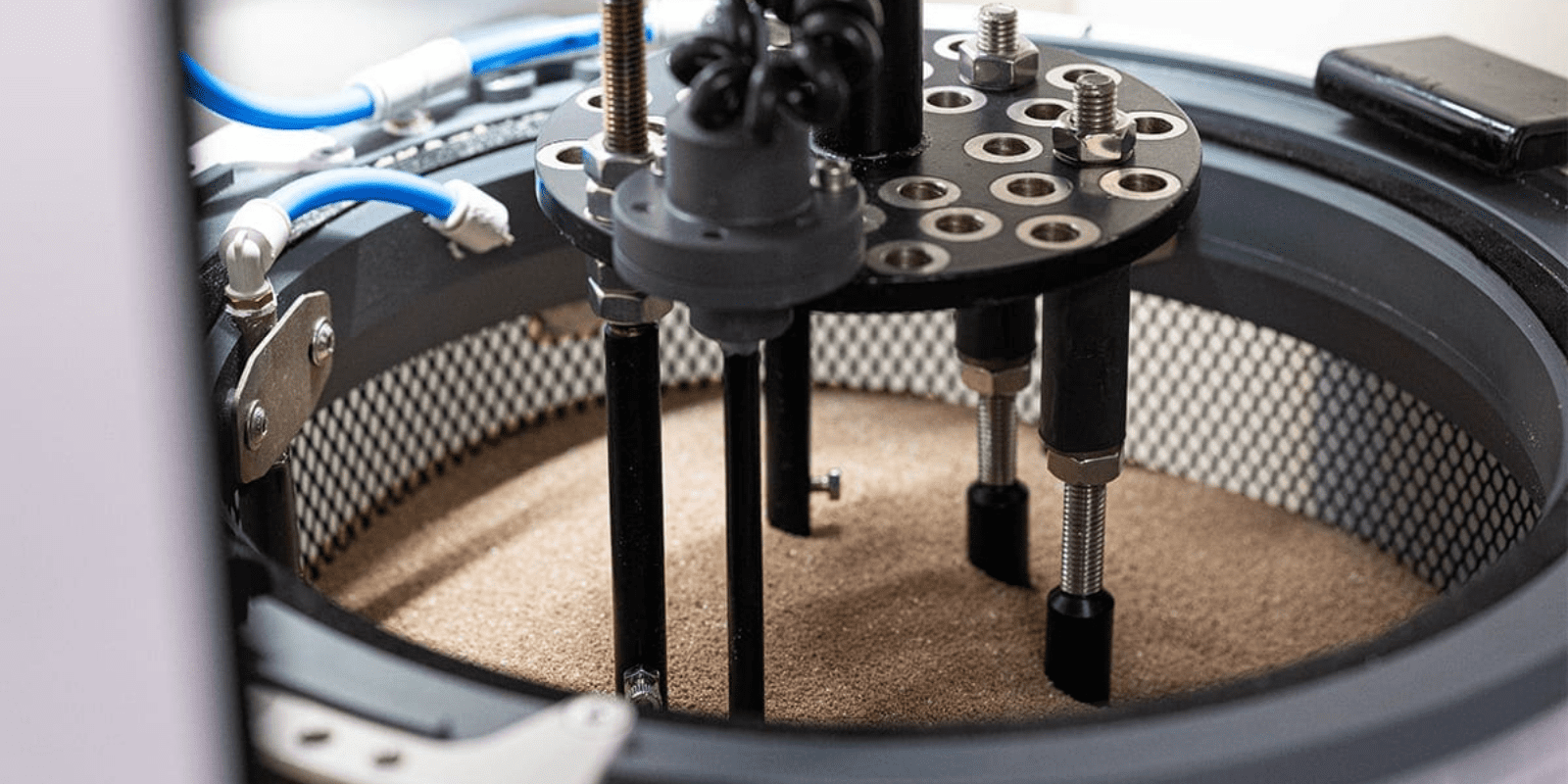

Our dry electropolishing machines

At ActOn Finishing, we provide a range of dry electropolishing machines to help our customers achieve the surface finish they need. In particular, the DLyte Technology machines ensure a quality finish time and time again, improving your production line processes, productivity and expenses overall.

DLyte Desktop PRO: designed to allow any manufacturer, workshop, workroom and SMEs, who would require a cost-effective solution for metal surface finishing, to use the dry electopolishing technology.

DLyte Compact Range: achieves high quality finishing for machined, sintered and casting parts, obtaining a mirror finish result. The polishing action reaches every corner of the piece, so it can process inner cavities which can not be accessed mechanically.

DLyte PRO Series: designed to include the largest compact dry electropolishing machines for industrial applications. This series includes a PRO and a PRO Carbide range.

DLyte PRO500: includes 2, 4 and 8 perimeter spindles, which enable it to handle either a single or multiple work pieces per holder, thereby enhancing its capacity and performance, even when working with large volumes of work pieces.

Download our brochure for more information on these highly efficient polishing machines, and get in touch with us if you have any queries, we’d be more than happy to help.