Superfinishing Process – What is it? Benefits and applications

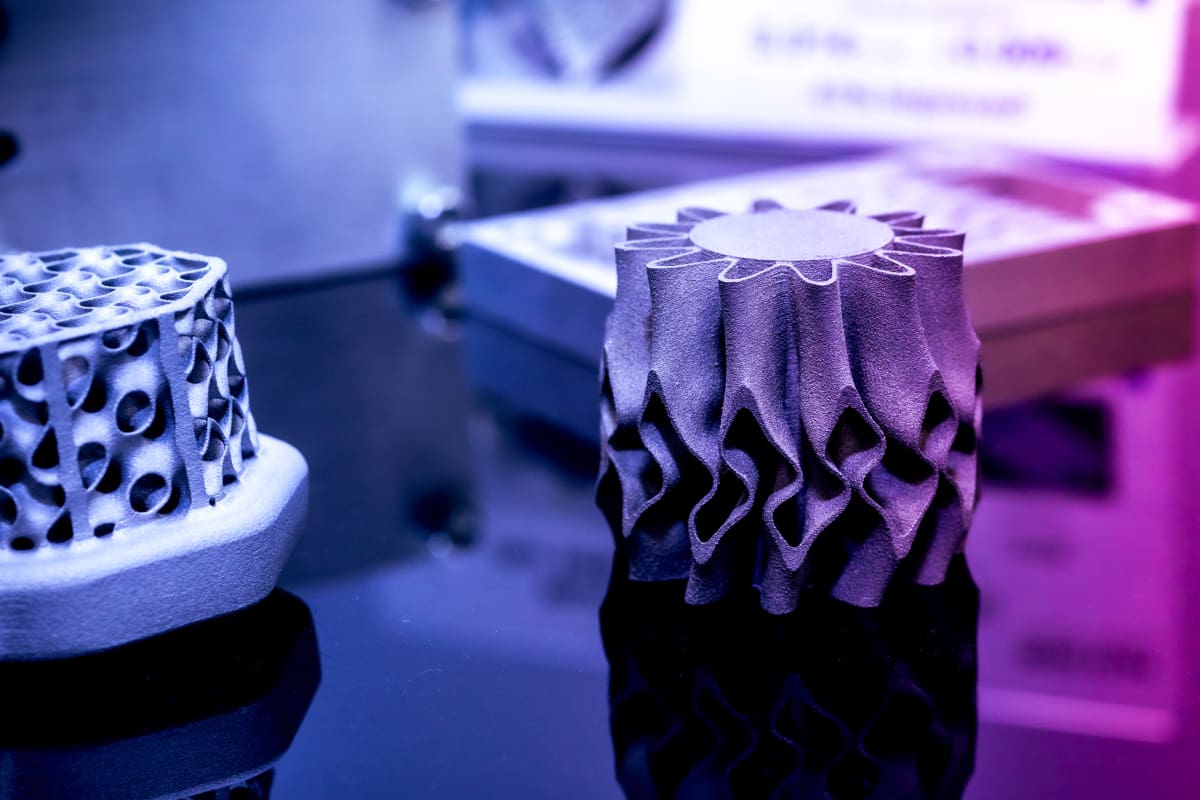

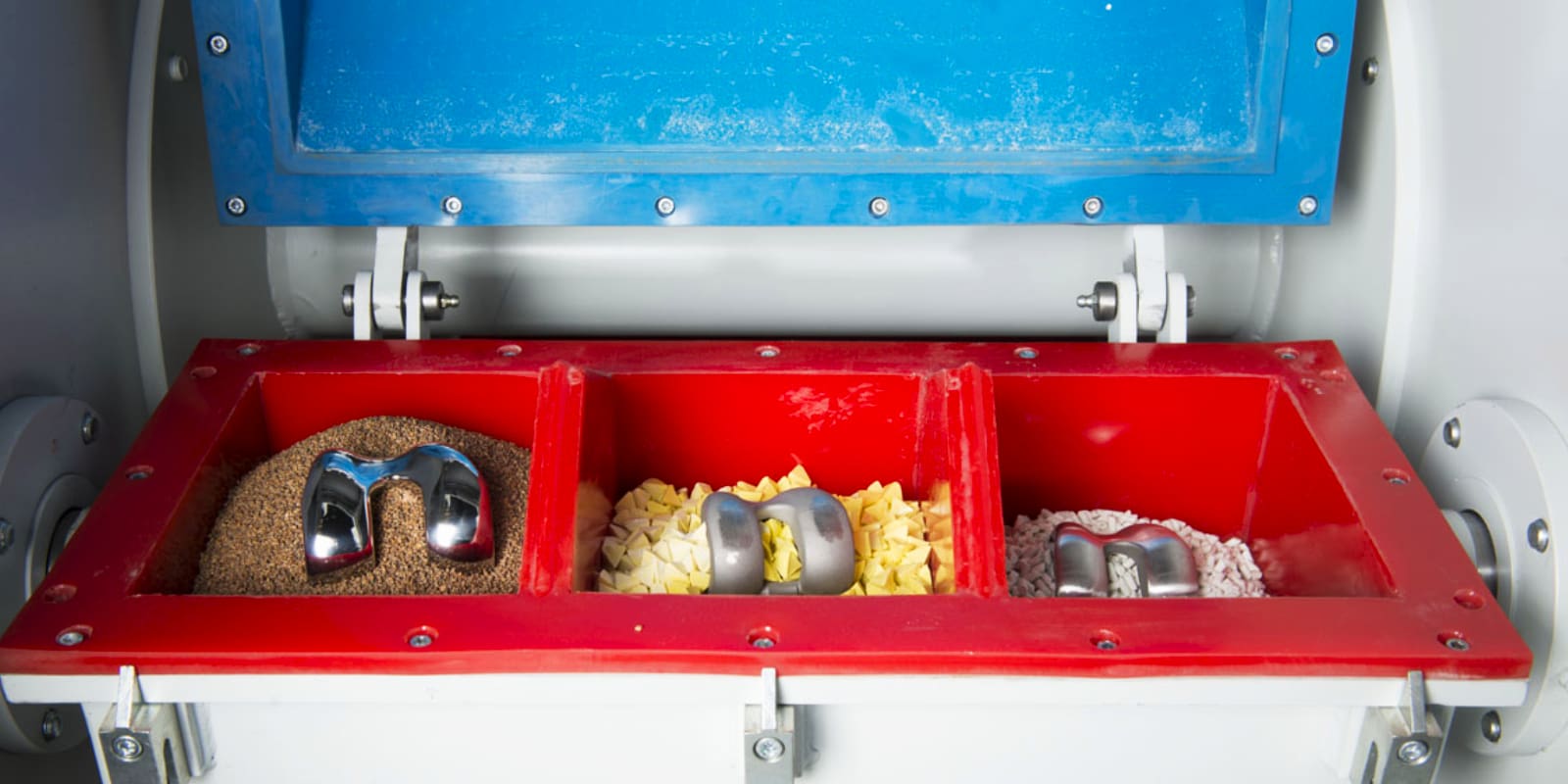

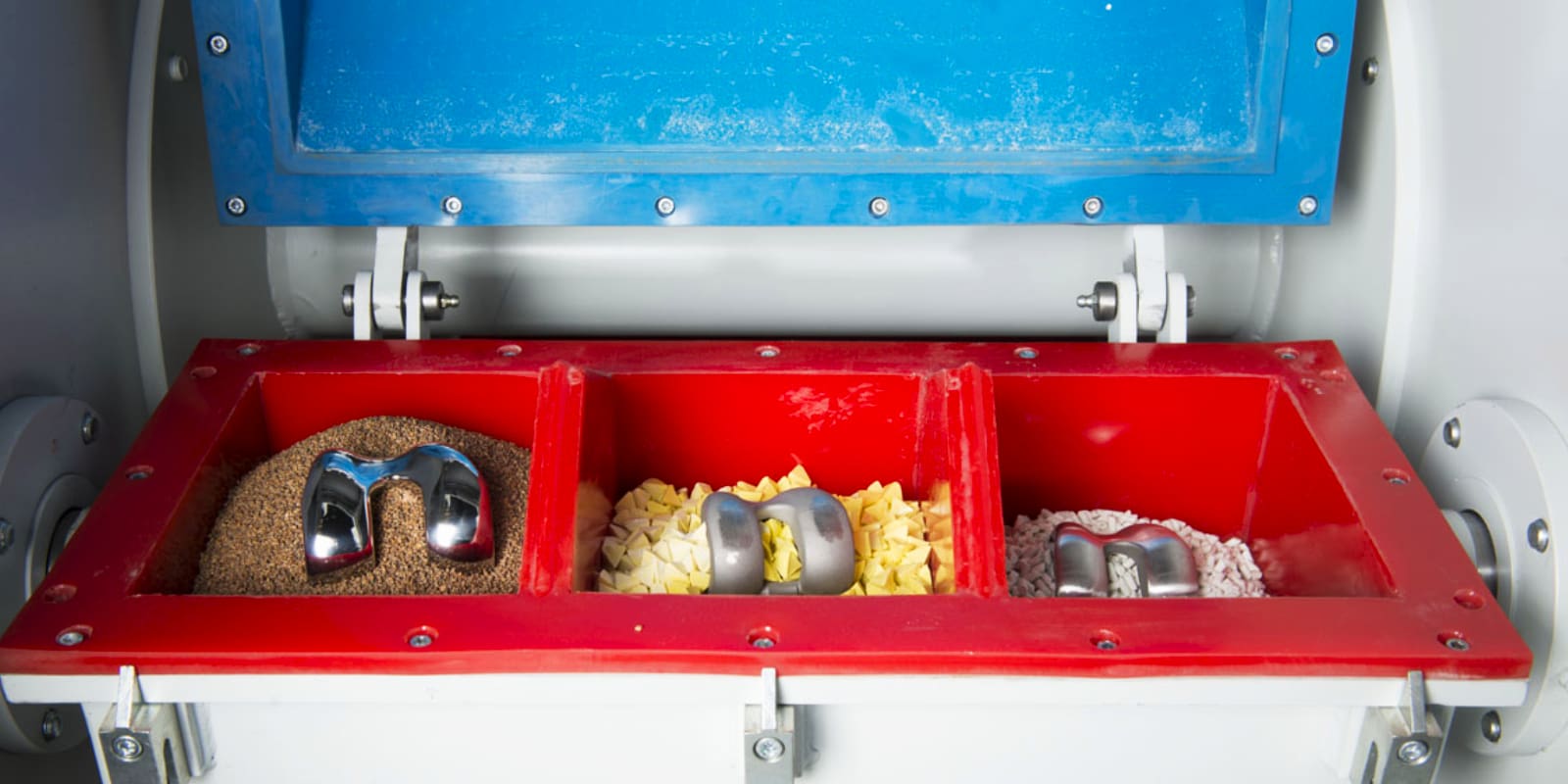

Understanding Superfinishing Superfinishing is a finishing process that aims to achieve an exceptionally smooth surface finish on a workpiece. Unlike conventional machining, which focuses primarily on shaping and rough finishing, superfinishing refines the surface texture to ultra-precise levels, often reducing roughness to mere microinches. The Process in Action At its core, superfinishing involves the… Read more »

Read more