In the world of surface preparation and restoration, where precision meets innovation, one method has been making waves – quite literally. Vapour blasting, a cutting-edge technique, has emerged as a game-changer in the realm of surface treatment. As industries strive for superior efficiency and environmental responsibility, wet blasting has become a beacon of hope, offering a solution that marries the finesse of abrasive blasting with the advantages of water-based technology.

Want to understand what vapour blasting is and the key benefits for this effective finishing method? Read our article…

What is vapour blasting?

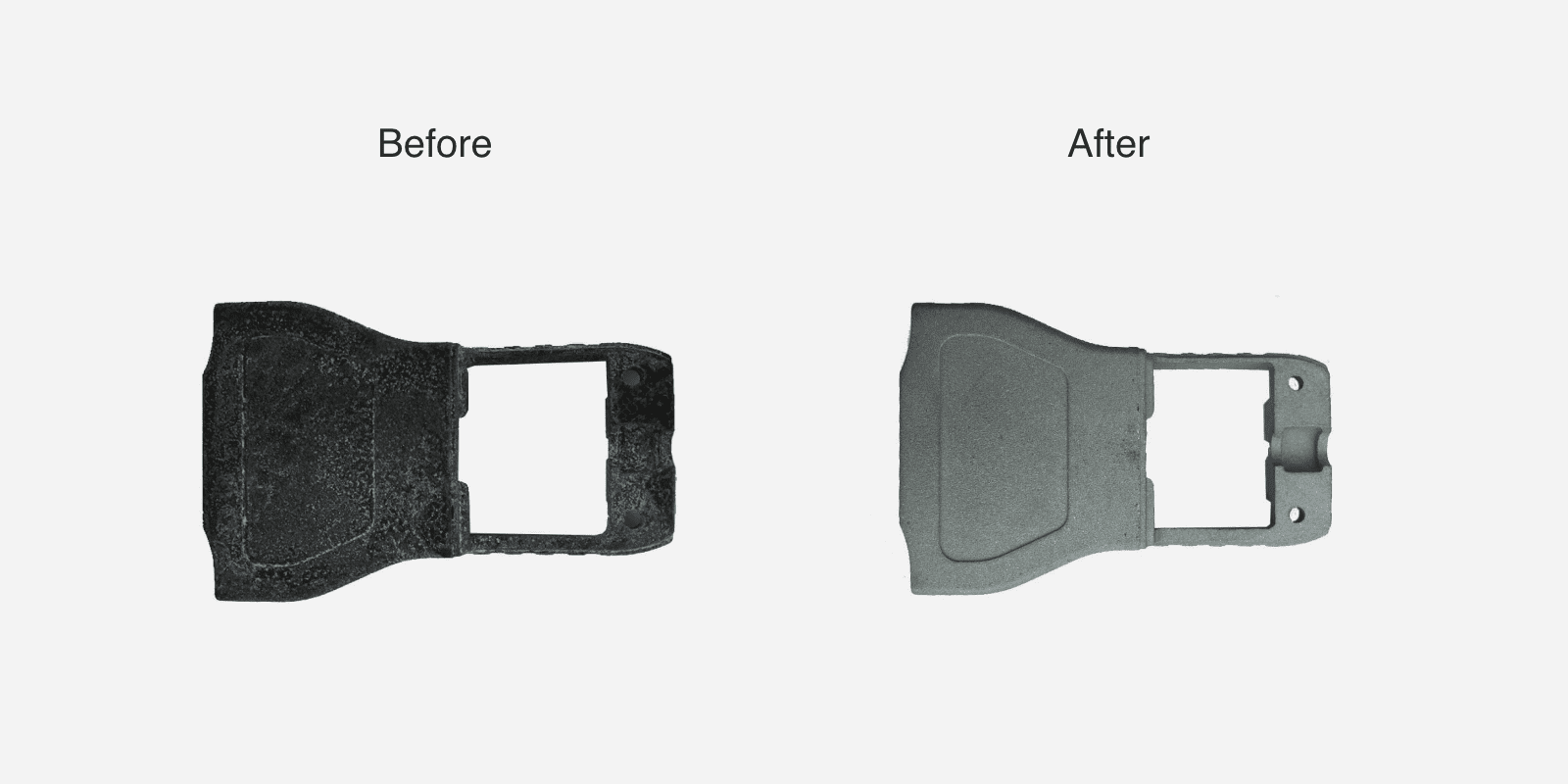

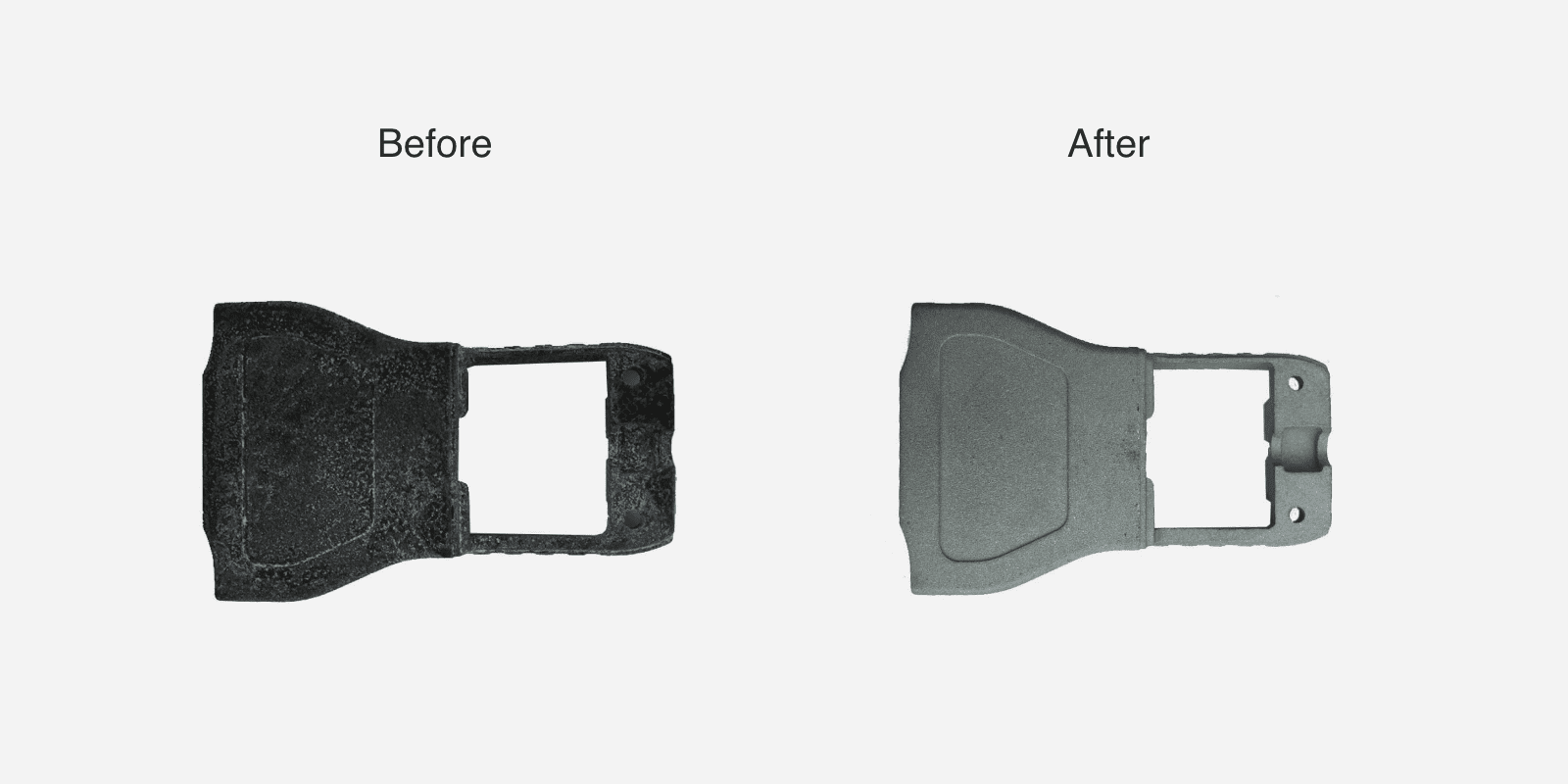

Put simply, vapour blasting, also often referred to as aqua blasting or wet blasting, is a surface preparation and cleaning process used to remove contaminants, coatings, and oxidation from various materials. It involves the use of a slurry mixture of abrasive media, water, and sometimes a cleaning agent.

So, now you know what vapour blasting is, but what are the main benefits of this finishing method?

What is the benefit of vapour blasting?

Vapour blasting actually has a wide range of benefits, which include:

Reduced dust emission: Vapour/ aqua blasting has a significantly reduced dust production, due to the water, which suppresses dust, making the process cleaner and more environmentally friendly. This is particularly beneficial in enclosed or sensitive environments where dust control is crucial

Gentle on surfaces: It’s generally gentler on surfaces compared to dry blasting. The water acts as a lubricant, reducing friction and heat generated during the blasting process. This makes it suitable for cleaning delicate or sensitive materials without causing damage.

Surface finish: The process often produces a smoother surface finish compared to dry blasting. The combination of abrasive media and water can provide a uniform and attractive appearance to the treated surface.

Less abrasive wear: The presence of water in the blasting process reduces wear and tear on equipment, including nozzles and hoses, compared to dry blasting. This can lead to lower maintenance costs and longer equipment lifespan.

Precise control: This process allows for more precise control over the blasting parameters. Adjustments can be made to the pressure, water-to-abrasive ratio, and nozzle configurations to achieve the desired results for different materials and applications.

Corrosion inhibition: In some wet blasting applications, rust inhibitors or cleaning agents can be added to the water, providing additional protection against corrosion. This is particularly useful when working with metal surfaces.

Versatility: It can be applied to a wide range of materials, including metals, plastics, composites, and more. Its versatility makes it suitable for various industries, such as automotive, aerospace, marine, and restoration.

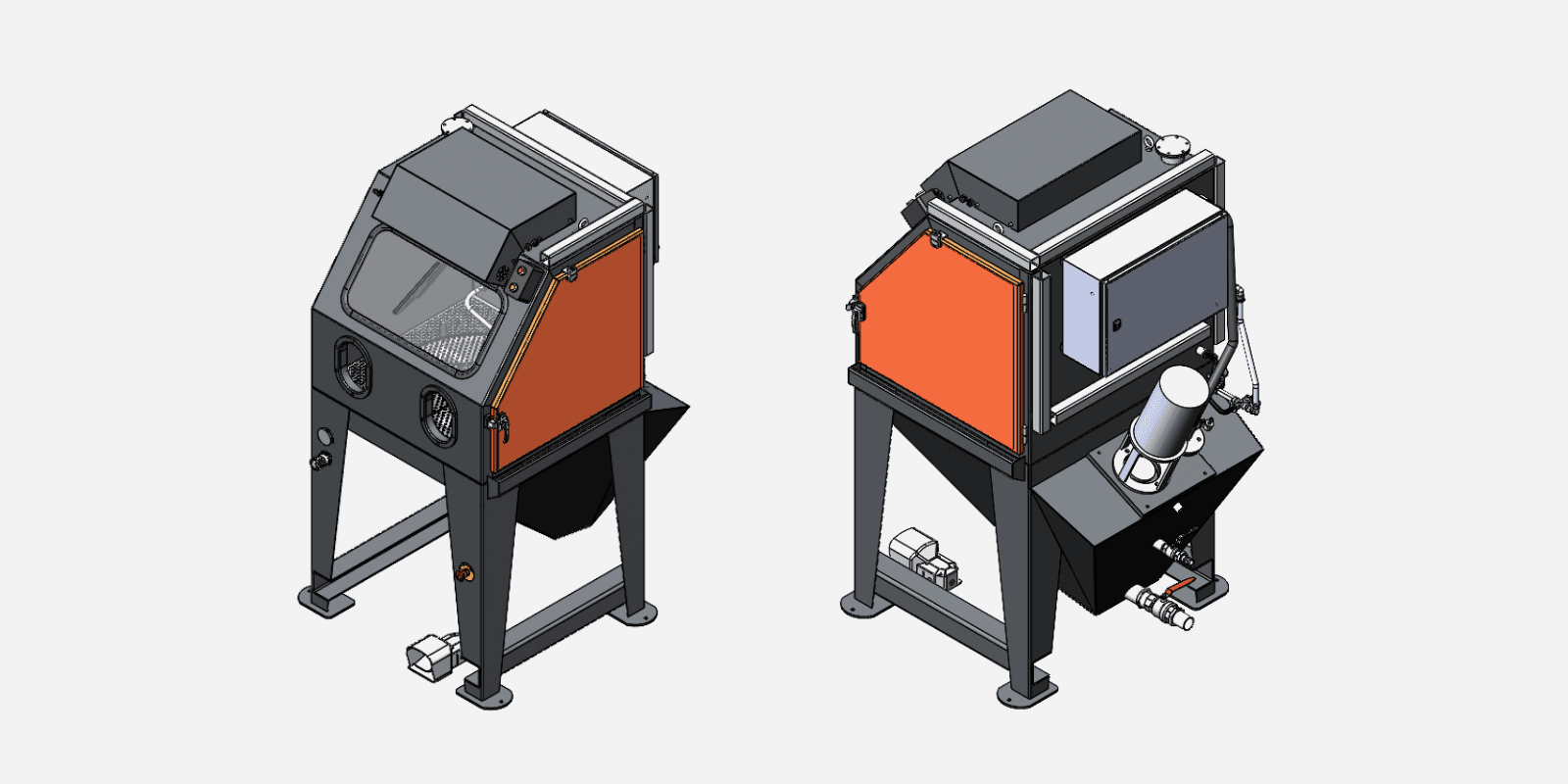

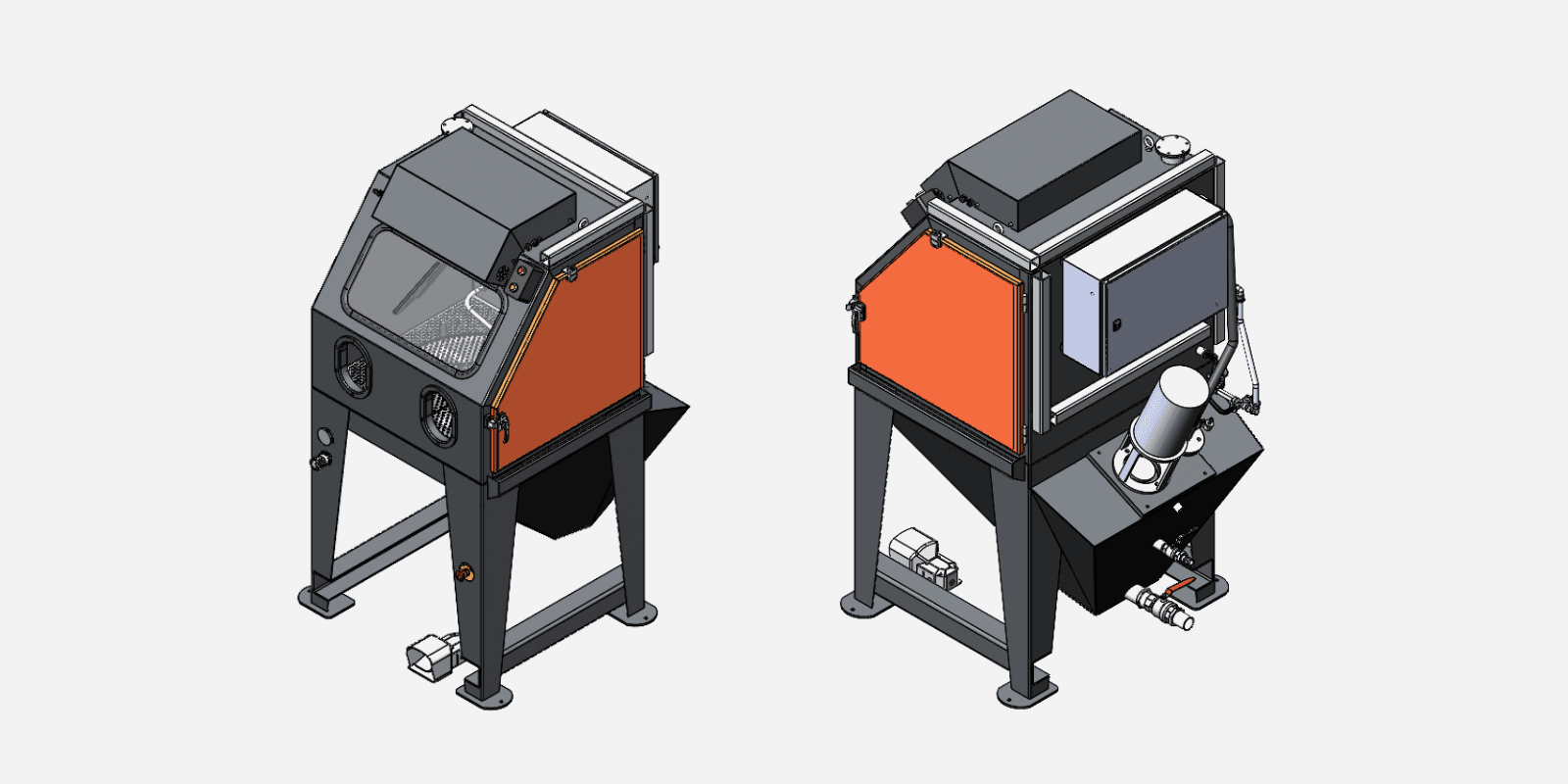

Now you know what vapour blasting is and its many benefits, you might want to start looking at our range of vapour blasting machines. Here at ActOn Finishing, we pride ourselves on supplying quality aqua blasting equipment to enhance your finishing methods and processes.

To find out more about our machines, download our brochure and get in touch with us to start achieving great finishing results.