-

-

-

- About

- Industries

-

Sub-Contracting

-

- Consumables

-

Cleaning

-

- All Ultrasonic Machines

- TT Standard Ultrasonic Series

- LT Pro Laboratory Ultrasonic Cleaning Machines

- MOT Automotive Ultrasonic Cleaning Machines

- One Tank Industrial Ultrasonic Cleaning Equipment

- Manual Multistage Ultrasonic Cleaning Equipment

- Multistage Automatic Ultrasonic Cleaning Machine

- Ultrasonic Generators

- Ultrasonic Cleaner Solution

-

-

Blasting & Peening

-

- All Shot Blasting Machines

- Powertrack Junior Portable Blast System

- Powertrack Portable Blast System

- ActOn Mobile Shot Blasting Room

- ECO Shot Blasting Machines

- Premium DI Suction Blasting Machines

- Premium DP Pressure Blasting Cabinets

- AWB Wet Blasting Cabinet

- Premium NP Wet Blasting Cabinets

- Automated Wet Blasting Machine

- NF Sandblasting Cabinets

- DLyte eBlast – Electro Shot Blaster

- AM Shot Peening and Blasting Series

- Automated Shot Blasting Equipment

- All Wheel Blasting Machines

- Spinner Hanger Blast Machine

- Tumble Rubber Belt Shot Blasting Machine

- Tumble Steel Belt Shot Blasting Machine

- Wire Mesh Belt Shot Blasting Machine

- Continuous Feed Overhead Rail Blasting Machine

- Roller Conveyor Blast Machine

- Continuous Feed Tube & Bar Blast Cleaning Machine

- Rotary Table Shot Blasting Machine

- Tunnel Concrete Shot Blast Machine

-

-

Surface Finishing

-

-

Surface Finishing

- All Mass Finishing Machines

- Vibratory Bowl Machines

- Vibratory Trough Machines

- Dual Finishing Machines

- Dryers

- Centrifugal High Energy Machines

- Disc Finishing Machines

- LE30 Rotary Barrel Machine

- Wheel Polishing Machine

- Automation for Mass Finishing

- Mass Finishing Accessories

- All Vibratory Machines

- Vibratory Dual Machines

- Vibratory Consumables

- Vibratory Bowl Machines

- Vibratory Trough Machines

- Dlyte Technology

- Waste Water Treatment

- REFURBISHED MACHINES

-

Blasting & Peening

- All Shot Blasting Machines

- Powertrack Junior Portable Blast System

- Powertrack Portable Blast System

- ActOn Mobile Shot Blasting Room

- ECO Shot Blasting Machines

- Premium DI Suction Blasting Machines

- Premium DP Pressure Blasting Cabinets

- AWB Wet Blasting Cabinet

- Premium NP Wet Blasting Cabinets

- Automated Wet Blasting Machine

- NF Sandblasting Cabinets

- DLyte eBlast – Electro Shot Blaster

- AM Shot Peening and Blasting Series

- Automated Shot Blasting Equipment

- All Wheel Blasting Machines

- Spinner Hanger Blast Machine

- Tumble Rubber Belt Shot Blasting Machine

- Tumble Steel Belt Shot Blasting Machine

- Wire Mesh Belt Shot Blasting Machine

- Continuous Feed Overhead Rail Blasting Machine

- Roller Conveyor Blast Machine

- Continuous Feed Tube & Bar Blast Cleaning Machine

- Rotary Table Shot Blasting Machine

- Tunnel Concrete Shot Blast Machine

- Refurbished Machines

-

Cleaning

- All Ultrasonic Machines

- TT Standard Ultrasonic Series

- LT Pro Laboratory Ultrasonic Cleaning Machines

- MOT Automotive Ultrasonic Cleaning Machines

- One Tank Industrial Ultrasonic Cleaning Equipment

- Manual Multistage Ultrasonic Cleaning Equipment

- Multistage Automatic Ultrasonic Cleaning Machine

- Ultrasonic Generators

- Ultrasonic Cleaner Solution

- Vibratory Finishing Machines

- Consumables

- Sub-Contracting

- Industries

- About

- Free Trial

- Contact us

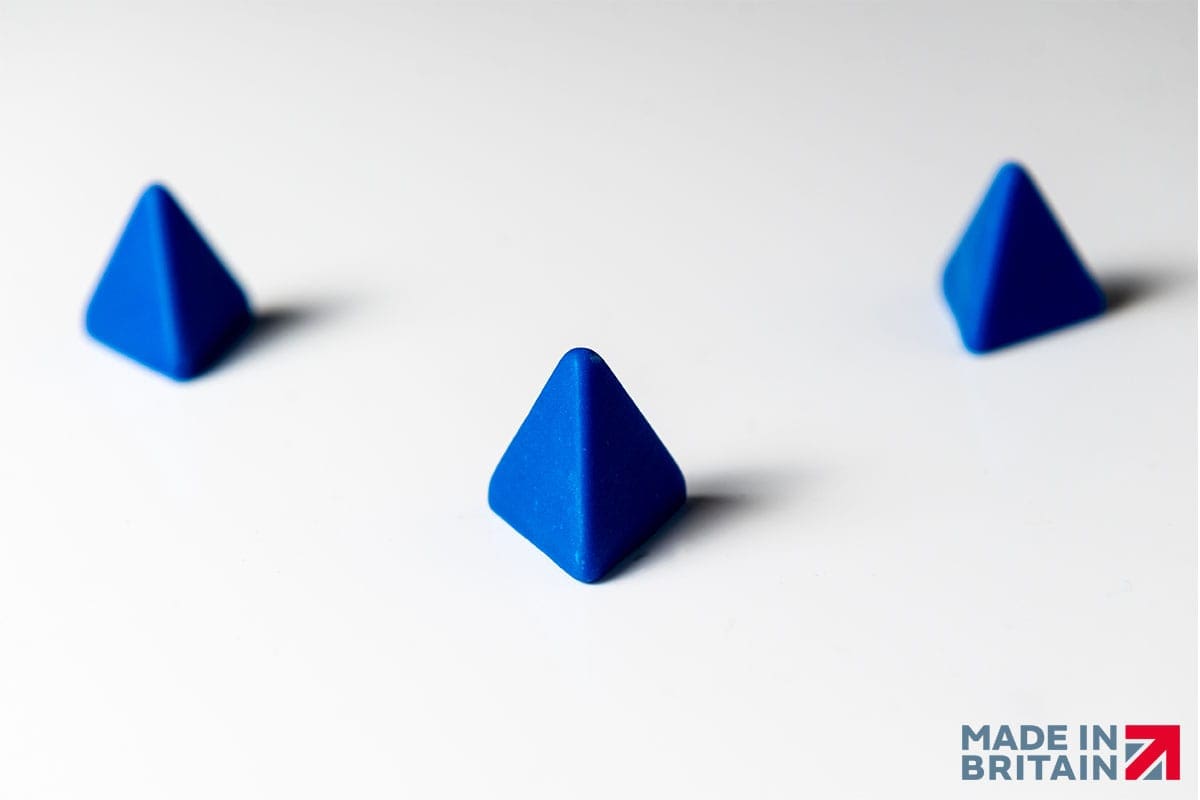

Pastes, Abrasive Powders and Compounds

As well as a comprehensive range of liquid compounds, ActOn Finishing offers a full range of Pastes, Abrasive Powders and Compounds. These are used for grinding, cleaning and polishing of ferrous and non-ferrous materials for vibratory and high energy finishing machines.

Abrasive Powders and Compounds for Special Processes

At ActOn we have developed a range of specialist compounds that achieve high specification surface finishes:

- Turbocut: a neutral special compound ideal for harden steel, great for rapid removal of surface defects on ferrous parts. The result is a smooth surface ready for post processing applications such as plating or painting.

- Chemcut: used for removing of grinding, linishing and machine marks. We recommend it for finishing parts made out of steel, hardened steel and certain stainless steels, as it gives rapid metal cut-down and levelling. Produces a super smooth surface, ready for polishing and elector-plating if required.

DOWNLOAD CHEMCUT TECHNICAL FLYER

Finishing Compounds for Special Processes

At ActOn we have developed a range of specialist compounds that achieve high specification surface finishes:

- ActoGrind: an abrasive paste used in vibratory finishing machines for removal of machining or grinding lines on ferrous & non-ferrous parts. Applications include polishing, descaling, de- rusting & removing light heat treatment marks.

- Separating Compound: keeps flat parts from sticking to each other in wet finishing processes. It is used in all types of vibratory and barrel finishing machines with all types of metals.

Technical Specifications

| Compound Name | Description | pH |

| A0 | An aggressive, coarse, concentrated, abrasive compound, used on harder metals for grinding, radiusing and the removal of heavy machine marks and burrs. Used with an abrasive media, it leaves the surface of parts with a shot-blast appearance. | 9-10 |

| A1 | A fast-cutting compound for heavy deburring and, combined with cleaning agents, it is mainly used for ferrous components, brass cuttings and pressings. Leaves the surface with a matte finish. | 11-12 |

| A2 | A medium, abrasive compound that is combined with cleaning agents. | 11-12 |

| A3 | A light deburring compound combined with cleaning agents for fine surface finishing of all materials, but mainly used on soft metals like zinc, brass or aluminium. It can also be used to bring back the surface on ceramic media which is contaminated. | 10-11 |

| A7 | It is a light grinding compound for cutting down and polishing that contains an extremely fine abrasive, which during the process breaks down into a slurry. This assists the polishing ingredients to impart a polished surface. | 9-10 |

| 35F | This is used for the cutting and polishing of non-ferrous metals and contains a soft abrasive with polishing agents. | 5-6 |

| P6 | It is used for polishing copper and its alloys with non-abrasive media. A silky foam lather is built which enhances the polishing process. | 9-10 |

| P51 | A polishing compound for aluminium with extra brightening and polishing agents giving superb results. Mainly used with steel media or plastic media to give a semi polished matte finish. | 9-10 |

| P71 | It produces a clean, bright lustre and keeps the metal in solution allowing the process to continue for long periods. This is suitable for zinc and zinc alloys. Mainly used with non-abrasive media. | 9-10 |

| C1 | Used to remove grease, oils and lubricating fluids leaving metal components clean and ready for further processes. | 12-13 |

| C4 | Used for cleaning of ferrous components and can be used with all types of media. | 12-13 |

| C5 | It keeps processes free of grease and oil. Good rust inhibitor. Mainly used on ferrous components. | 12-13 |

| C6 | Cleaning compound with brightening and is used on ferrous components to give a clean bright surface finish. It contains a strong rust inhibitor. Abrasive and polishing media can be used with C6 compound. | 11-12 |

| ActoClean BT (C7) | Used mainly on ferrous components to give a clean surface finish. It contains strong rust inhibitor. | 11-12 |

| C50 | Suitable for processing all metals. Copes with all types of oily and greasy components. Contains corrosion inhibitor and can be used with all types of media. | 10-11 |

For further technical specifications and more information on our range of Abrasive Powders and Compounds, please download our brochure.

DOWNLOAD BROCHUREREQUEST A FREE TRIAL