-

-

-

- About

- Industries

-

Sub-Contracting

-

- Consumables

-

Cleaning

-

- All Ultrasonic Machines

- TT Standard Ultrasonic Series

- LT Pro Laboratory Ultrasonic Cleaning Machines

- MOT Automotive Ultrasonic Cleaning Machines

- One Tank Industrial Ultrasonic Cleaning Equipment

- Manual Multistage Ultrasonic Cleaning Equipment

- Multistage Automatic Ultrasonic Cleaning Machine

- Ultrasonic Generators

- Ultrasonic Cleaner Solution

-

-

Blasting & Peening

-

- All Shot Blasting Machines

- Powertrack Junior Portable Blast System

- Powertrack Portable Blast System

- ActOn Mobile Shot Blasting Room

- ECO Shot Blasting Machines

- Premium DI Suction Blasting Machines

- Premium DP Pressure Blasting Cabinets

- AWB Wet Blasting Cabinet

- Premium NP Wet Blasting Cabinets

- Automated Wet Blasting Machine

- NF Sandblasting Cabinets

- DLyte eBlast – Electro Shot Blaster

- AM Shot Peening and Blasting Series

- Automated Shot Blasting Equipment

- All Wheel Blasting Machines

- Spinner Hanger Blast Machine

- Tumble Rubber Belt Shot Blasting Machine

- Tumble Steel Belt Shot Blasting Machine

- Wire Mesh Belt Shot Blasting Machine

- Continuous Feed Overhead Rail Blasting Machine

- Roller Conveyor Blast Machine

- Continuous Feed Tube & Bar Blast Cleaning Machine

- Rotary Table Shot Blasting Machine

- Tunnel Concrete Shot Blast Machine

-

-

Surface Finishing

-

-

Surface Finishing

- All Mass Finishing Machines

- Vibratory Bowl Machines

- Vibratory Trough Machines

- Dual Finishing Machines

- Dryers

- Centrifugal High Energy Machines

- Disc Finishing Machines

- LE30 Rotary Barrel Machine

- Wheel Polishing Machine

- Automation for Mass Finishing

- Mass Finishing Accessories

- All Vibratory Machines

- Vibratory Dual Machines

- Vibratory Consumables

- Vibratory Bowl Machines

- Vibratory Trough Machines

- Dlyte Technology

- Waste Water Treatment

- REFURBISHED MACHINES

-

Blasting & Peening

- All Shot Blasting Machines

- Powertrack Junior Portable Blast System

- Powertrack Portable Blast System

- ActOn Mobile Shot Blasting Room

- ECO Shot Blasting Machines

- Premium DI Suction Blasting Machines

- Premium DP Pressure Blasting Cabinets

- AWB Wet Blasting Cabinet

- Premium NP Wet Blasting Cabinets

- Automated Wet Blasting Machine

- NF Sandblasting Cabinets

- DLyte eBlast – Electro Shot Blaster

- AM Shot Peening and Blasting Series

- Automated Shot Blasting Equipment

- All Wheel Blasting Machines

- Spinner Hanger Blast Machine

- Tumble Rubber Belt Shot Blasting Machine

- Tumble Steel Belt Shot Blasting Machine

- Wire Mesh Belt Shot Blasting Machine

- Continuous Feed Overhead Rail Blasting Machine

- Roller Conveyor Blast Machine

- Continuous Feed Tube & Bar Blast Cleaning Machine

- Rotary Table Shot Blasting Machine

- Tunnel Concrete Shot Blast Machine

- Refurbished Machines

-

Cleaning

- All Ultrasonic Machines

- TT Standard Ultrasonic Series

- LT Pro Laboratory Ultrasonic Cleaning Machines

- MOT Automotive Ultrasonic Cleaning Machines

- One Tank Industrial Ultrasonic Cleaning Equipment

- Manual Multistage Ultrasonic Cleaning Equipment

- Multistage Automatic Ultrasonic Cleaning Machine

- Ultrasonic Generators

- Ultrasonic Cleaner Solution

- Vibratory Finishing Machines

- Consumables

- Sub-Contracting

- Industries

- About

- Free Trial

- Contact us

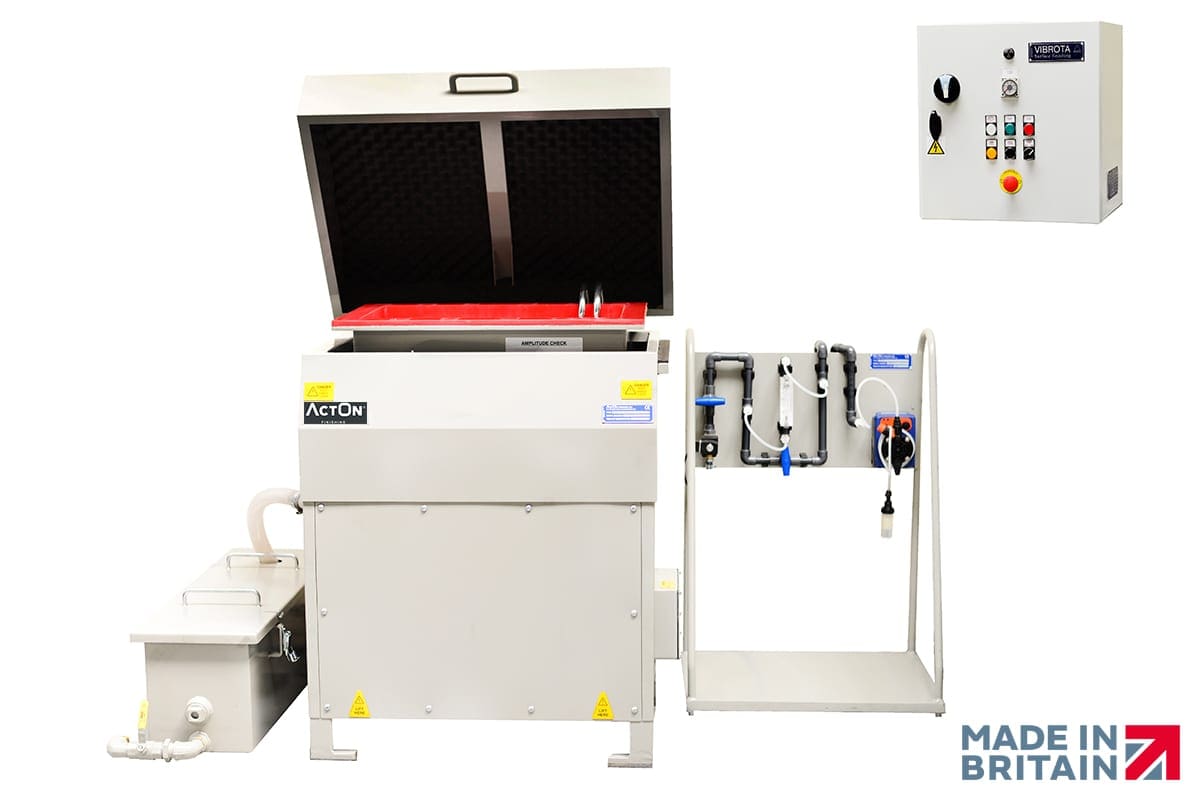

Vibratory Finishing Troughs

We offer Vibratory Tumblers and Finishing Troughs in many different sizes and an infinite choice of length and width combinations, making them one of our most versatile ranges of vibro machines. These Vibratory Tumblers are perfect for mass finishing larger, longer and irregular-shaped components.

Get a quoteKey Benefits

- British built, high-quality vibratory tumblers

- Efficient in operation

- Quiet in operation

- Operator friendly controls

- Low maintenance

- Manual / Auto functionality

- Customised to suit user applications

- Several processing chambers can be made with use of dividers

- Solutions include both batch type and continuous online vibratory finishing systems

Key Features

- High quality wear-resistant polyurethane lining

- The divider plate fixture system is designed to offer flexibility in changing the chamber size, to suit the part geometry.

- Design ensures ease of customisation.

- Easy to access working chamber.

- Gives flexibility to process large or irregular shaped components.

- Ergonomical and easy to use.

Vibratory Finishing Trough Specifications

| Series | Model | Capacity | Overall dimensions in mm / inch | Chamber dimension in mm / inch after lining | Max Motor Rating (kW) | |||||

| Cu. Ft. | Litres | Length | Width | Height | Length | Width | Height | |||

| HT Series | HT2 | 2 | 60 | 825 / 32.5 | 725 / 28.5 | 971 / 38.2 | 575 / 22.6 | 395 / 15.5 | 368 / 14.5 | 0.34 (1500 rpm) 0.50 (3000 rpm) |

| TU Series | TU3 | 3 | 85 | 1000 / 39.4 | 850 / 33.5 | 1085 / 42.7 | 575 / 22.6 | 370 / 14.5 | 445 / 17.5 | 0.95 |

| TU4 | 4 | 113 | 1225 / 48.2 | 850 / 33.5 | 1085 / 42.7 | 800 / 31.5 | 370 / 14.5 | 445 / 17.5 | 1.2 | |

| TU7 | 7 | 198 | 1725 / 67.9 | 850 / 33.5 | 1085 / 42.7 | 1300 / 51.2 | 370 / 14.5 | 445 / 17.5 | 1.7 | |

| TU9 | 9 | 255 | 2075 / 81.7 | 850 / 33.5 | 1250 / 49.2 | 1650 / 64.9 | 370 / 14.5 | 445 / 17.5 | 2.2 | |

| TU10 | 10 | 283 | 1670 / 65.7 | 1000 / 39.4 | 1280 / 50.4 | 1185 / 46.6 | 450 / 17.7 | 560 / 22 | 2.2 | |

| TU12 | 12 | 340 | 1325 / 52.1 | 1255 / 48.2 | 1485 / 58.5 | 895 / 35.2 | 645 / 25.4 | 710 / 27.9 | 2.2 | |

| TU14 | 14 | 397 | 2135 / 84.1 | 1000 / 39.4 | 1280 / 50.4 | 1650 / 64.9 | 450 / 17.7 | 560 / 22 | 2.8 | |

| TU20 | 20 | 567 | 1970 / 77.5 | 1255 / 48.2 | 1485 / 58.5 | 1540 / 60.6 | 650 / 25.6 | 710 / 27.9 | 6 | |

| TU30 | 30 | 850 | 2000 / 78.7 | 1400 / 55 | 1650 / 64.9 | 1520 / 59.8 | 770 / 30.3 | 810 / 31.8 | 7 | |

| TU50 | 50 | 1417 | 3600 / 141.7 | 1350 / 53.1 | 1800 / 70.8 | 3000 / 118.1 | 770 / 30.3 | 700 / 27.6 | 11 | |

| TUT Series | TUT29 | 29 | 792 | 2930/115.4 | 1350/53.1 | 1470/57.9 | 1600/63 | 960/37.8 | 800/31.5 | 2x2.5 |

| TUT40 | 40 | 1040 | 3350/131.9 | 1460/57.5 | 1600/63 | 1800/70.9 | 1000/39.4 | 850/33.5 | 2x5 | |

| TUT60 | 60 | 1596 | 3550/139.8 | 1620/63.8 | 1770/69.7 | 2000/78.7 | 1150/45.3 | 1000/39.4 | 2x7 | |

| TUT80 | 80 | 2197 | 3800/149.6 | 1720/67.7 | 1820/71.6 | 2200/86.6 | 1250/49.2 | 1100/43.3 | 2x7 | |

| Notes: | ||||||||||

| 1. Sizes indicated above are standard. Custom sizes can be manufactured to suit specific applications. Dimensions are subject to change due to design improvements. | ||||||||||

| 2. Please check our Vibratory Finishing brochure for further technical information on all our vibratory trough series. | ||||||||||