-

-

-

- About

- Industries

-

Sub-Contracting

-

- Consumables

-

Cleaning

-

- All Ultrasonic Machines

- TT Standard Ultrasonic Series

- LT Pro Laboratory Ultrasonic Cleaning Machines

- MOT Automotive Ultrasonic Cleaning Machines

- One Tank Industrial Ultrasonic Cleaning Equipment

- Manual Multistage Ultrasonic Cleaning Equipment

- Multistage Automatic Ultrasonic Cleaning Machine

- Ultrasonic Generators

- Ultrasonic Cleaner Solution

-

-

Blasting & Peening

-

- All Shot Blasting Machines

- Powertrack Junior Portable Blast System

- Powertrack Portable Blast System

- ActOn Mobile Shot Blasting Room

- ECO Shot Blasting Machines

- Premium DI Suction Blasting Machines

- Premium DP Pressure Blasting Cabinets

- AWB Wet Blasting Cabinet

- Premium NP Wet Blasting Cabinets

- Automated Wet Blasting Machine

- NF Sandblasting Cabinets

- DLyte eBlast – Electro Shot Blaster

- AM Shot Peening and Blasting Series

- Automated Shot Blasting Equipment

- All Wheel Blasting Machines

- Spinner Hanger Blast Machine

- Tumble Rubber Belt Shot Blasting Machine

- Tumble Steel Belt Shot Blasting Machine

- Wire Mesh Belt Shot Blasting Machine

- Continuous Feed Overhead Rail Blasting Machine

- Roller Conveyor Blast Machine

- Continuous Feed Tube & Bar Blast Cleaning Machine

- Rotary Table Shot Blasting Machine

- Tunnel Concrete Shot Blast Machine

-

-

Surface Finishing

-

-

Surface Finishing

- All Mass Finishing Machines

- Vibratory Bowl Machines

- Vibratory Trough Machines

- Dual Finishing Machines

- Dryers

- Centrifugal High Energy Machines

- Disc Finishing Machines

- LE30 Rotary Barrel Machine

- Wheel Polishing Machine

- Automation for Mass Finishing

- Mass Finishing Accessories

- All Vibratory Machines

- Vibratory Dual Machines

- Vibratory Consumables

- Vibratory Bowl Machines

- Vibratory Trough Machines

- Dlyte Technology

- Waste Water Treatment

- REFURBISHED MACHINES

-

Blasting & Peening

- All Shot Blasting Machines

- Powertrack Junior Portable Blast System

- Powertrack Portable Blast System

- ActOn Mobile Shot Blasting Room

- ECO Shot Blasting Machines

- Premium DI Suction Blasting Machines

- Premium DP Pressure Blasting Cabinets

- AWB Wet Blasting Cabinet

- Premium NP Wet Blasting Cabinets

- Automated Wet Blasting Machine

- NF Sandblasting Cabinets

- DLyte eBlast – Electro Shot Blaster

- AM Shot Peening and Blasting Series

- Automated Shot Blasting Equipment

- All Wheel Blasting Machines

- Spinner Hanger Blast Machine

- Tumble Rubber Belt Shot Blasting Machine

- Tumble Steel Belt Shot Blasting Machine

- Wire Mesh Belt Shot Blasting Machine

- Continuous Feed Overhead Rail Blasting Machine

- Roller Conveyor Blast Machine

- Continuous Feed Tube & Bar Blast Cleaning Machine

- Rotary Table Shot Blasting Machine

- Tunnel Concrete Shot Blast Machine

- Refurbished Machines

-

Cleaning

- All Ultrasonic Machines

- TT Standard Ultrasonic Series

- LT Pro Laboratory Ultrasonic Cleaning Machines

- MOT Automotive Ultrasonic Cleaning Machines

- One Tank Industrial Ultrasonic Cleaning Equipment

- Manual Multistage Ultrasonic Cleaning Equipment

- Multistage Automatic Ultrasonic Cleaning Machine

- Ultrasonic Generators

- Ultrasonic Cleaner Solution

- Vibratory Finishing Machines

- Consumables

- Sub-Contracting

- Industries

- About

- Free Trial

- Contact us

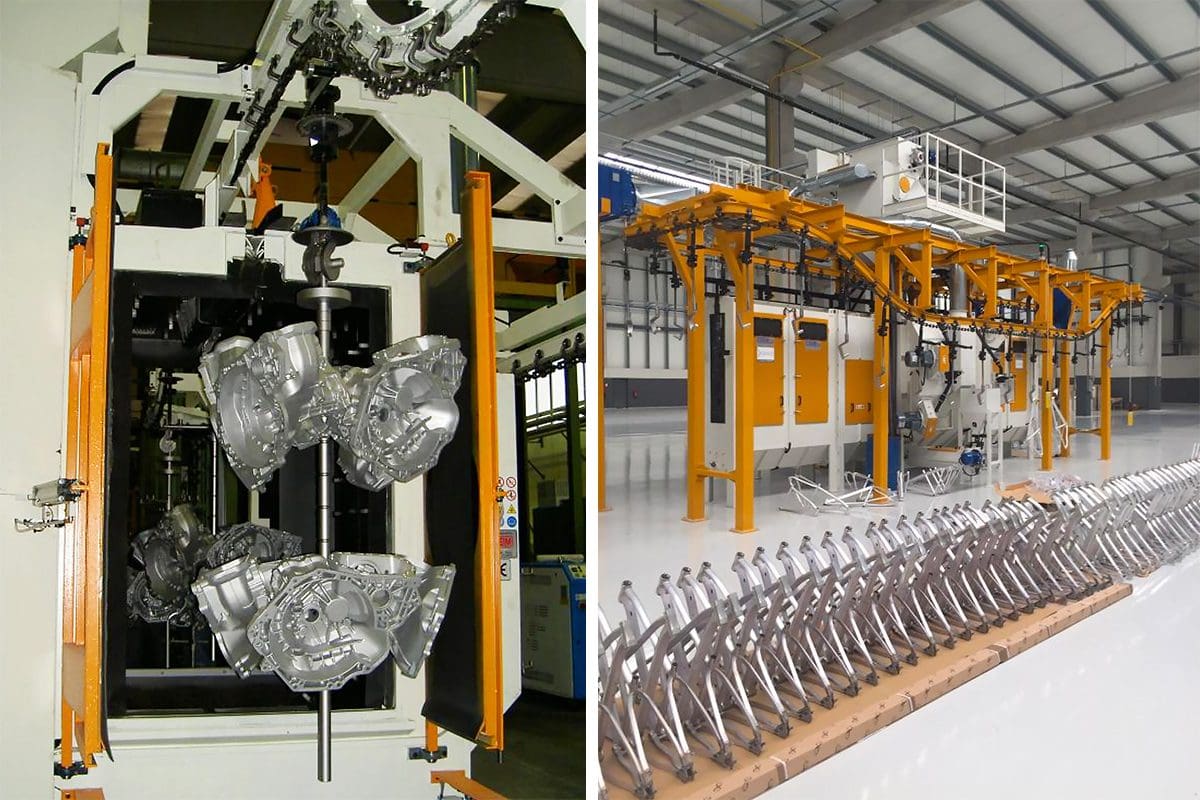

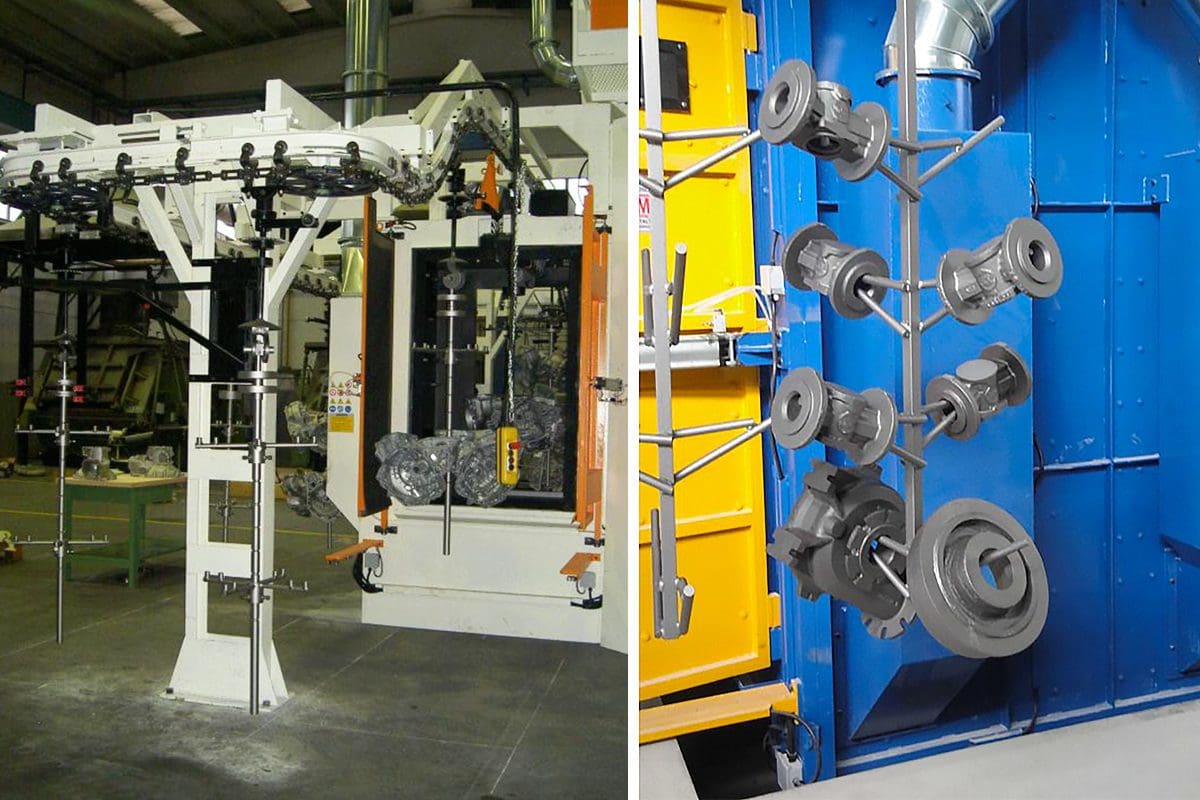

GSA Series - Continuous Feed Overhead Rail Blasting Machine

GSA Continuous Feed Overhead Rail Blasting Machine is built for treatment of components hanged on a hook which run on a O-ring motorised overhead rail. The displacement of hangers is automatic with a step by step system to ensure a constant productivity. This shot blasting equipment is widely used by steel, cast iron and aluminium foundries for the surface cleaning of metallic products.

Get a quoteHow it works?

Parts are loaded on hooks and transported into the Continuous Feed Overhead Rail Blasting Machine via a O-ring motorised overhead rail. Components are then shot blasted by powerful turbines in the blasting cabinet. At the end of the finishing process, parts exist the blasting machine.

DOWNLOAD BROCHUREKey Features and Benefits of The GSA Series – Continuous Feed Overhead Rail Blasting Machine

- Can accommodate parts with different shapes and sizes.

- Recommended for shot blasting components which can’t be processed in bulk.

- Powerful turbines for efficient finishing result.

- Automatic working cycle.

- Efficient in operation.

- Operator friendly controls.

- Solid construction.

Technical Specifications

For further technical specifications on our GSA Series – Continuous Feed Overhead Rail Blasting Machines, please download our brochure.

DOWNLOAD BROCHURE