We are happy to announce that ActOn team will be present at the Southern Manufacturing & Electronics Show 2024 between the 6th and 8th of February, which will take plat at Farnborough International Exhibition and Conference Centre.

Southern Manufacturing & Electronics Show 2024 stands as an important event for everyone engaged in design, engineering production, and procurement. It provides a comprehensive showcase of cutting-edge production hardware, components, consumables, and technology across diverse industries such as Aerospace, Defence, Automotive, Electronics, Industrial Machinery, Packaging/Handling/Logistics, Energy, Marine, Medical, Mechanical Engineering, and Metal Processing. Attendees have the invaluable opportunity to network and establish connections with the foremost figures in the manufacturing industry. This year is the 4th consecutive year when ActOn will be present at the show, at stand G170, where our technical representatives will be present to address any inquiries regarding your surface finishing needs.

What to expect from ActOn at Southern Manufacturing & Electronics Show 202

- You can be the first to find out about our new Wet Blasting Technology range. The AWB is an affordable wet blasting cabinet that offers convenient operation in both sitting and standing positions. It is specifically designed for various applications such as cleaning, descaling, deburring, roughening, oil or grease removal, and die cleaning. With this machine, you can achieve a remarkably smooth finish on your components.

- We will showcase our Ultrasonic Cleaning Range. These systems are designed to clean, descale and strip a large range of pars, for industries such as automotive, aerospace, energy, electronics, food, graphics, jewellery, marine, mould cleaning, medical, optical and more.

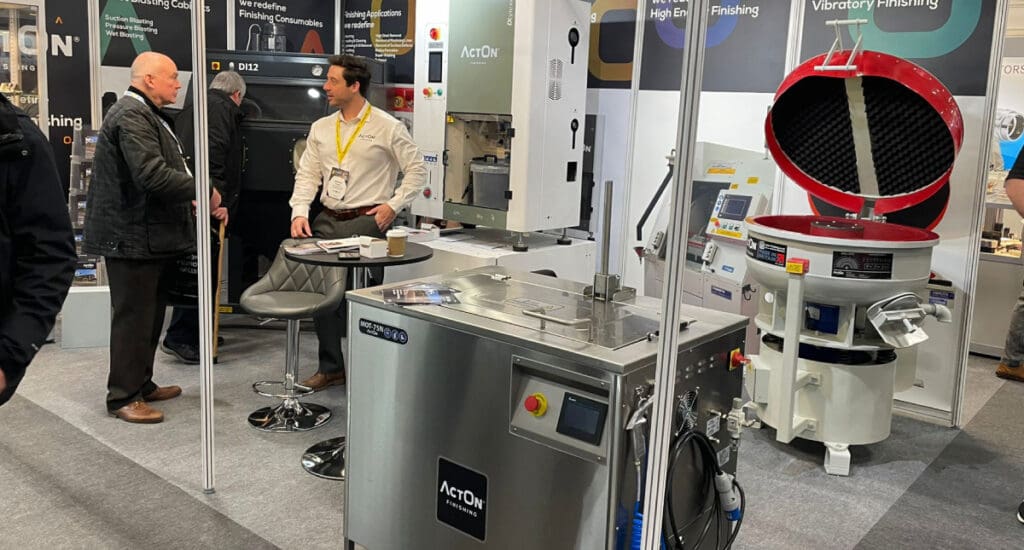

- Learn about the latest Surface Finishing Technology available and how it can be applied on your components. You will be able to check at our stand, VB1S system. This machine is ideally suited for small batch works and delicate components. Moreover we will showcase the DI12 suction blasting machine, a cabinet equipped with a cyclone and blasting pistol which guarantees an effective and efficient blasting process

- Discover our Centrifugal High Energy machines, more than 20 times faster than traditional Vibratory Finishing machines.

- Already have a finishing machine? Then we recommend checking our range of finishing consumables. From ceramic media, plastic media, shot blasting & peening media, agro and pre-treated media, burnishing media to liquid compounds & abrasive powders & pastes, these consumables will offer you superior processing results.

- We have prepared a range of parts which we have finished over the past year and you can check these at our stand at Southern Manufacturing & Electronics Show 2024. We believe that by seeing the actual results you can get in our surface finishing machines is a good way to visualise what you can obtain at your site.

- If you lack the expertise, necessary capacity, or readiness to invest in surface finishing equipment but require a finishing solution, ActOn provides specialised services. Our team is ready to engage in discussions with you to determine the optimal Finishing Subcontract Solutions for your specific needs. Opting for our subcontract services brings several advantages, including:

-

- Quick turnaround time based on the delivery time of components from customer.

- Controlled subcontract processes to ensure constant high quality finishing on all components.

- Transport option available to facilitate a quick turnaround time.

- Free Trial and technical consultation to ensure finishing result is as per customer’s requirement.

… still not convinced? Here are a few more reasons why you should join us:

We take pride in being the foremost authority in the United Kingdom for designing and developing surface finishing machinery, consumables, and subcontract surface finishing solutions. At ActOn Finishing, our offerings encompass solutions for vibratory finishing, high-energy finishing, shot blasting and wheel blasting, electropolishing, ultrasonic cleaning and waste water treatment. Our versatile equipment is well-suited for various applications, including but not limited to deburring, descaling, polishing, cleaning, mirror finishing, radiusing, smoothing, drying, and more.

“We are the only manufacturers in the UK of this type of equipment and we very much focus on process development, which is tailored to our customer needs. Moreover, all materials and machinery are subjected to extensive testing at our laboratory, ensuring the efficiency of our process is continually improving.”, says Sid Gulati, Managing Director at ActOn.