Join us as we take a closer look at vapour blasting machine applications, and the industries our equipment best serves. And if you’re not sure on what vapour blasting is and how it can help your business, click here to discover more about vapour blasting.

Vapour blasting machine applications

The versatility of vapour blasting machines and their ability to achieve a clean and controlled surface finish, while minimising environmental impact contributes to its widespread use in different applications, including;

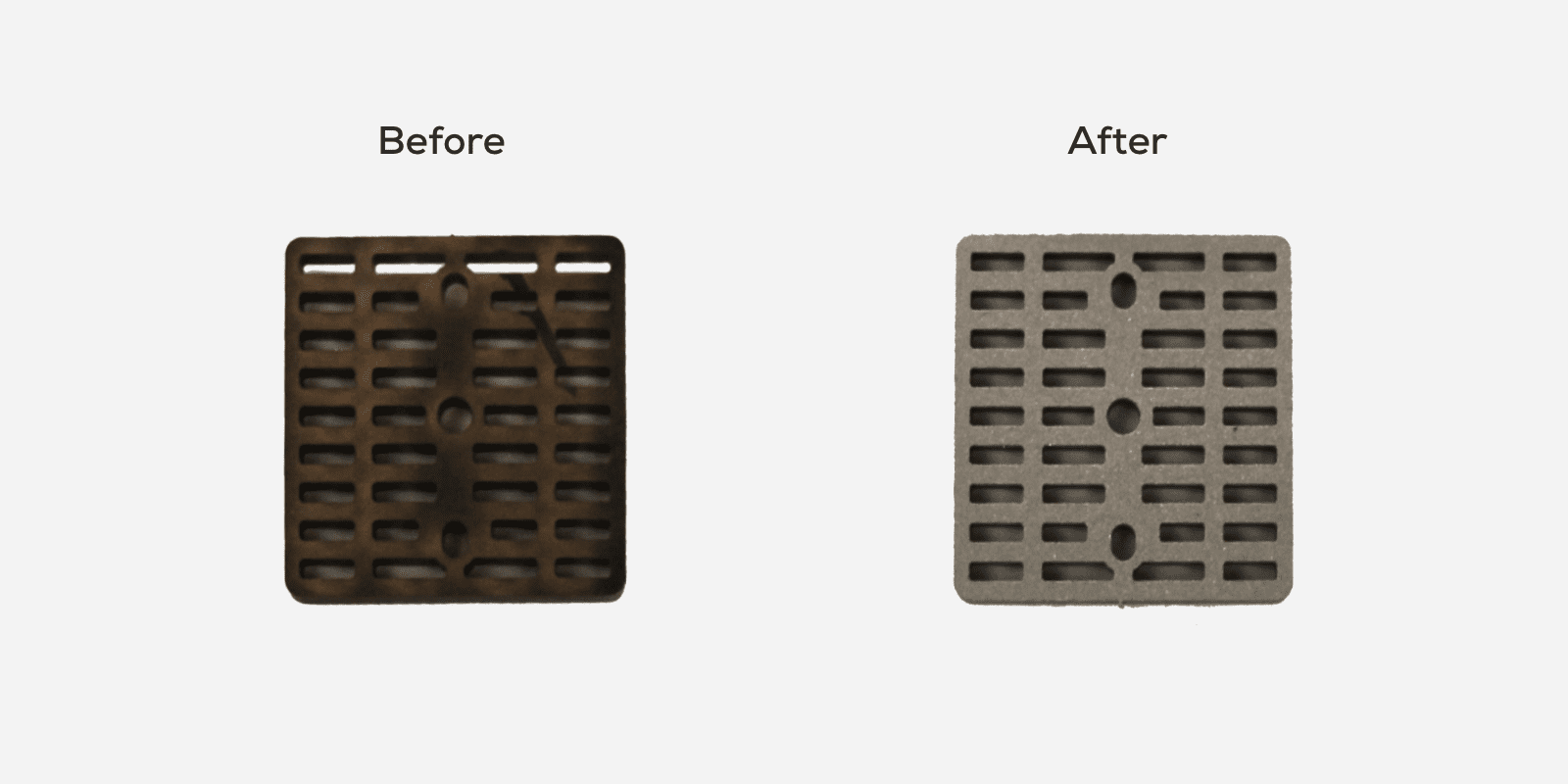

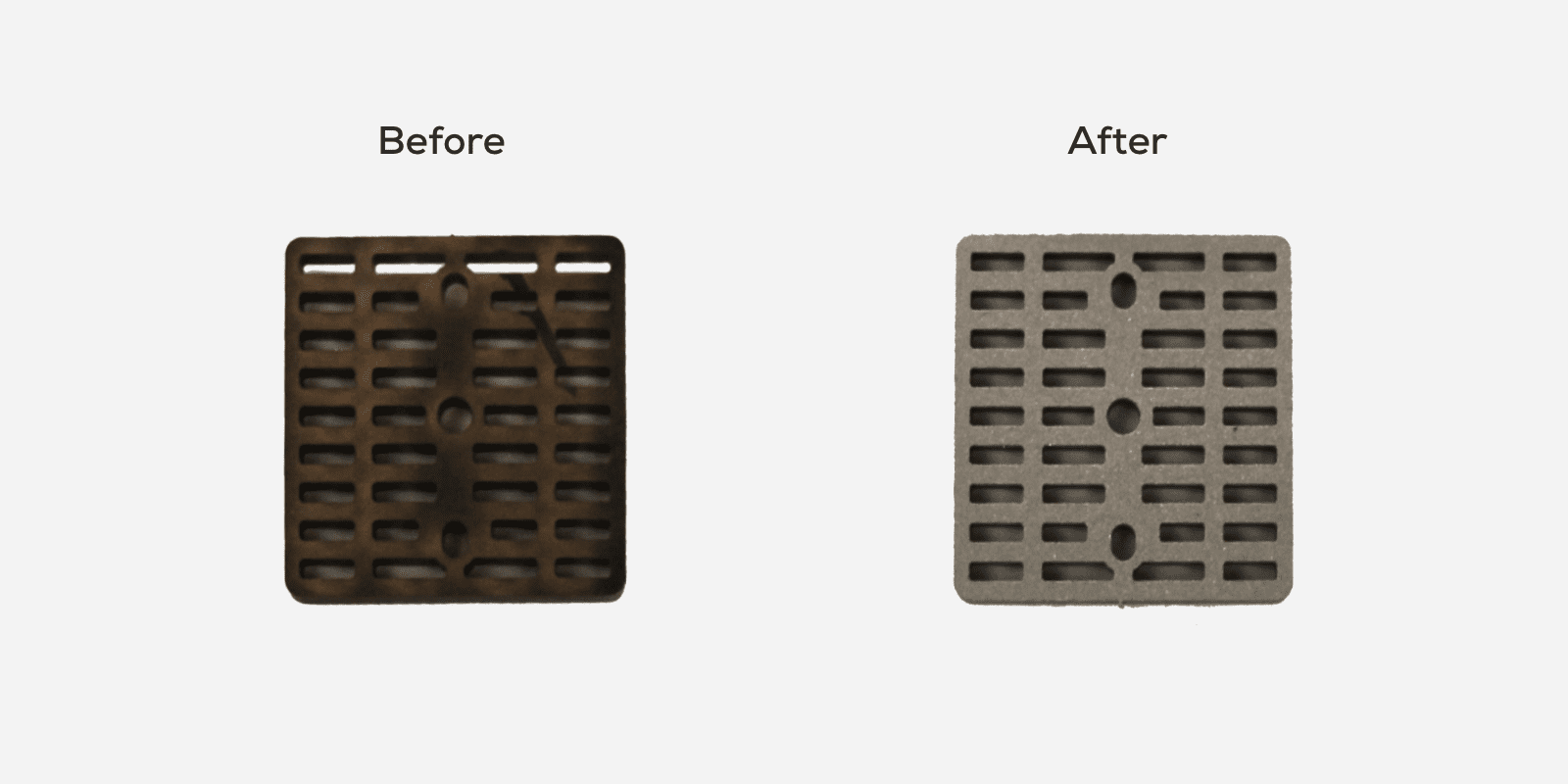

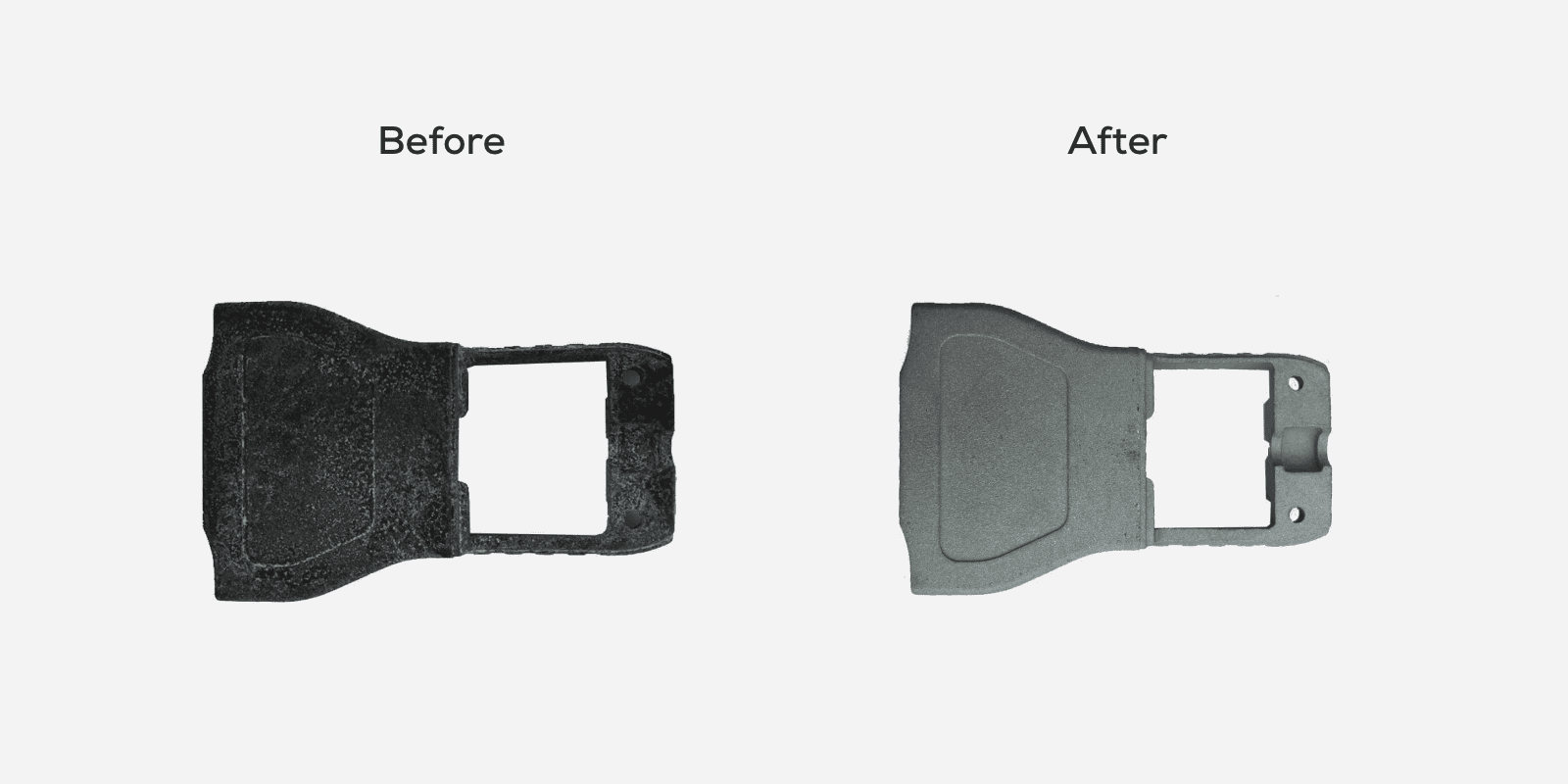

Surface cleaning: Vapour/Aqua blasting is effective in removing contaminants such as dirt, grease, oil, and rust from surfaces. It provides a thorough cleaning that can restore the original appearance of the material.

Paint removal: These machines are often used to strip paint or coatings from surfaces. The combination of abrasive media and water helps break down and remove layers of paint without causing significant damage to the underlying material.

Rust removal: Vapour/Wet blasting is particularly useful for removing rust from metal surfaces. The abrasive action, combined with water, can efficiently eliminate rust and corrosion, preparing the surface for further treatments like painting or coating.

Surface preparation: Vapour blasting machines are employed as a surface preparation method before applying coatings, adhesives, or other treatments. It creates a clean, roughened surface that enhances the adhesion of subsequent materials.

Aluminium and non-ferrous metal cleaning: This finishing method is suitable for cleaning aluminium and other non-ferrous metals, without causing damage or leaving behind abrasive residues. It helps maintain the integrity of the metal surface.

Deburring and surface finishing: Vapour blasting machines can be used for deburring and surface finishing of precision parts. It smoothes edges, removes burrs, and provides a uniform finish, making it suitable for applications where a high-quality surface is required.

Removal of scale and oxidation: Vapour blasting machines can effectively remove scale, oxidation, and heat discolouration from metal surfaces. This is useful in industries where maintaining the integrity of metal components is critical.

Industry-specific applications

Engine component cleaning: In automotive and aviation industries, vapour blasting is often used to clean engine components, cylinder heads, and other parts. The process is gentle enough to avoid damaging sensitive components while effectively removing grime and deposits.

Restoration of automotive parts: Vapour blasting machines are popular in the restoration of classic and vintage cars. It can be used to clean and prepare various automotive parts, such as carburettors, engine blocks, and chassis components, without causing damage to delicate surfaces.

Architectural restoration: This process is utilised in the restoration of architectural elements, such as stone, concrete, and metal structures. Vapour blasting machines are used to clean and rejuvenate surfaces without causing damage to historical or delicate materials.

Industries that would benefit from vapour blasting machines

The versatility of vapour blasting machines makes this finishing method valuable in various industries, including;

- Automotive and aerospace

- Marine

- Construction

- Restoration

- Jewellery

Discover our experience with your industry.

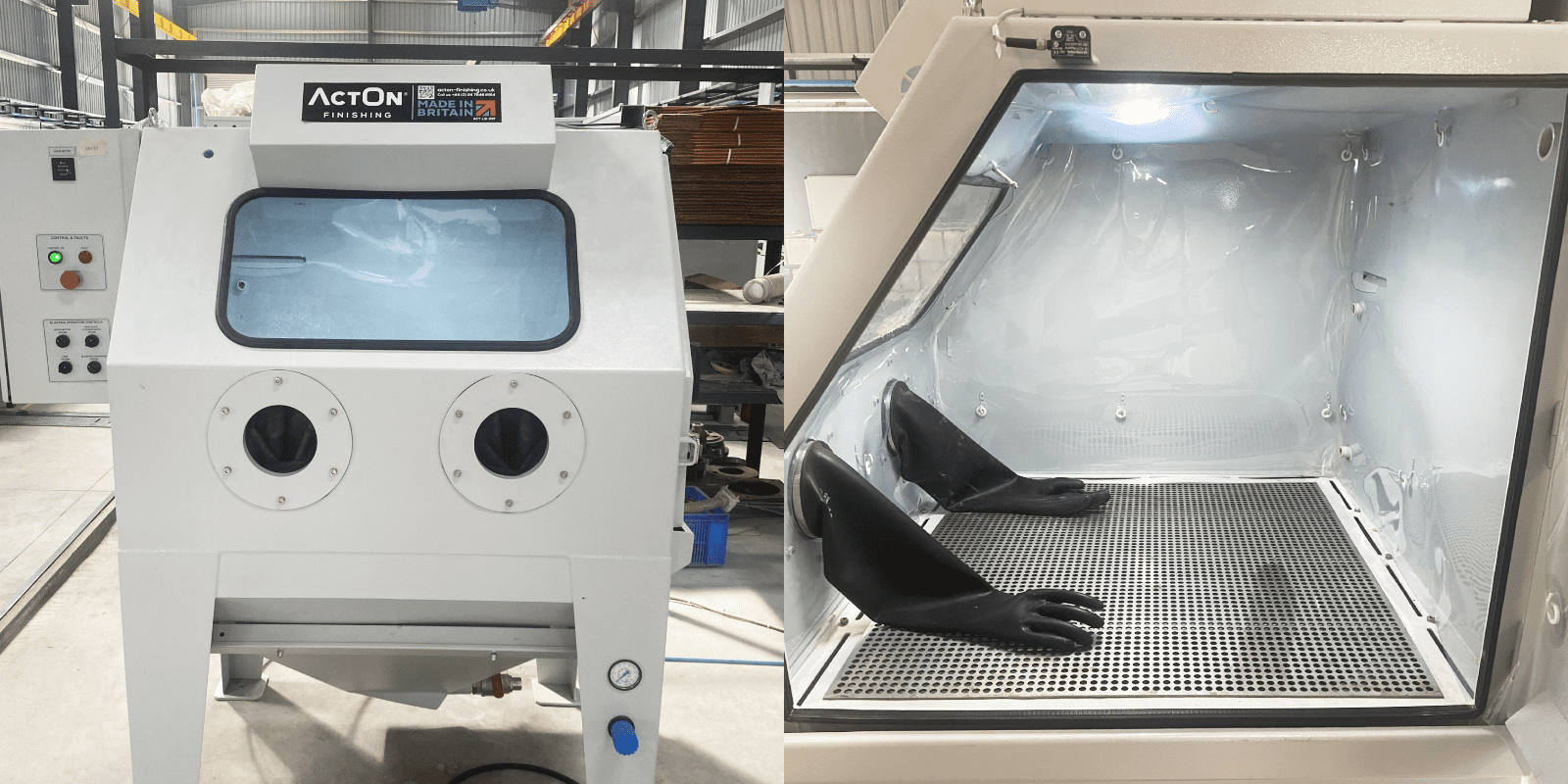

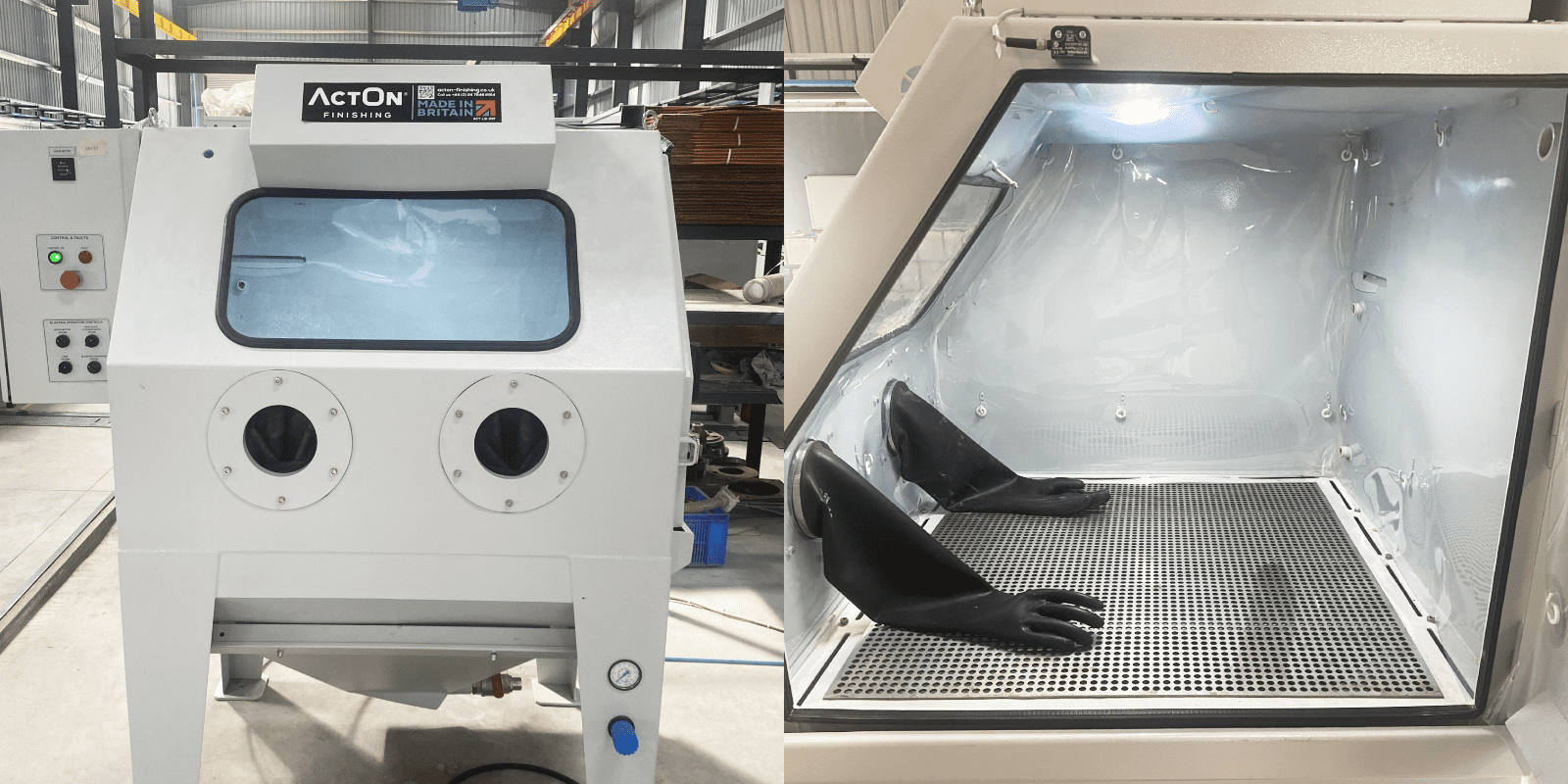

Our vapour blasting machines

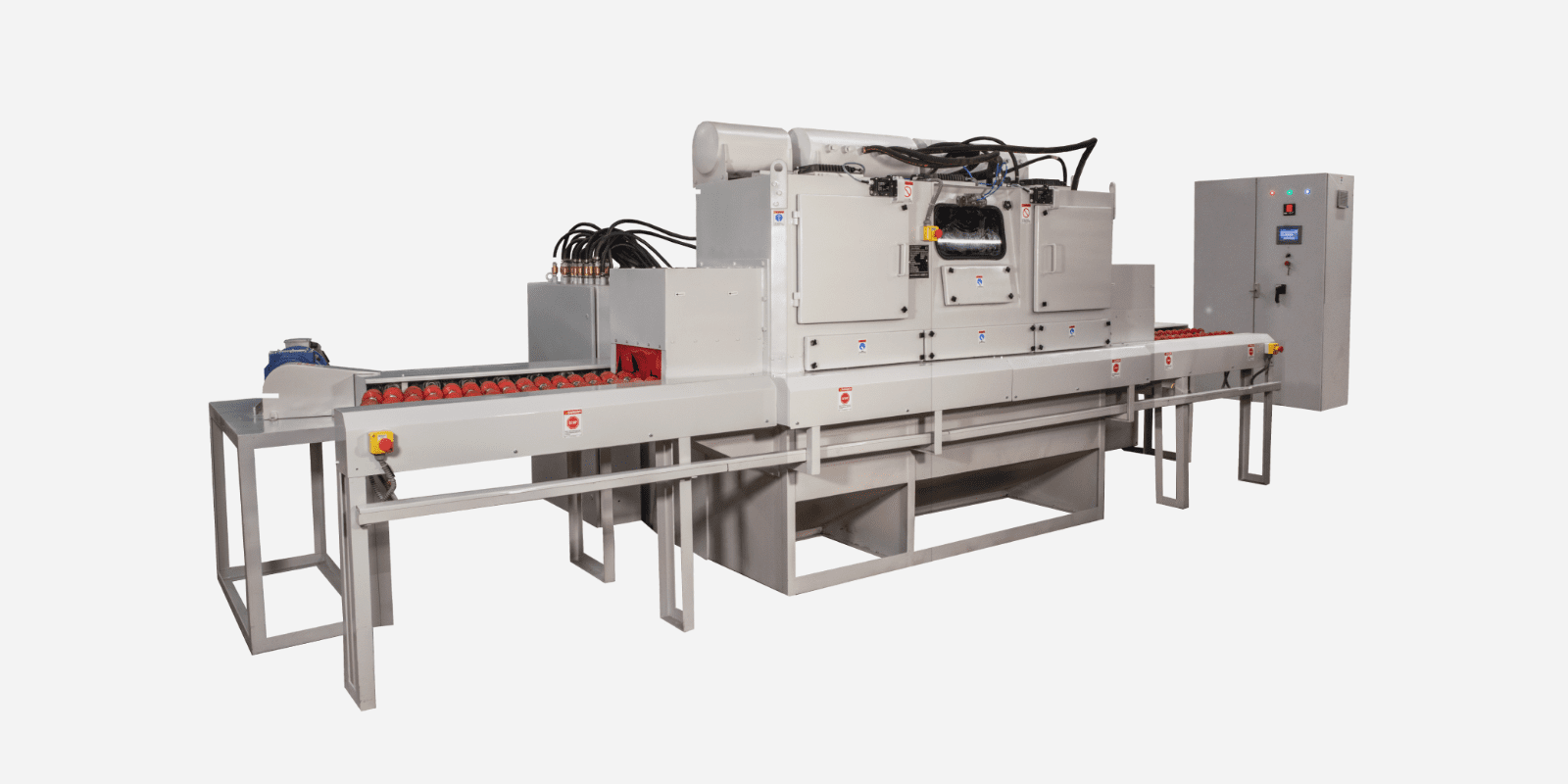

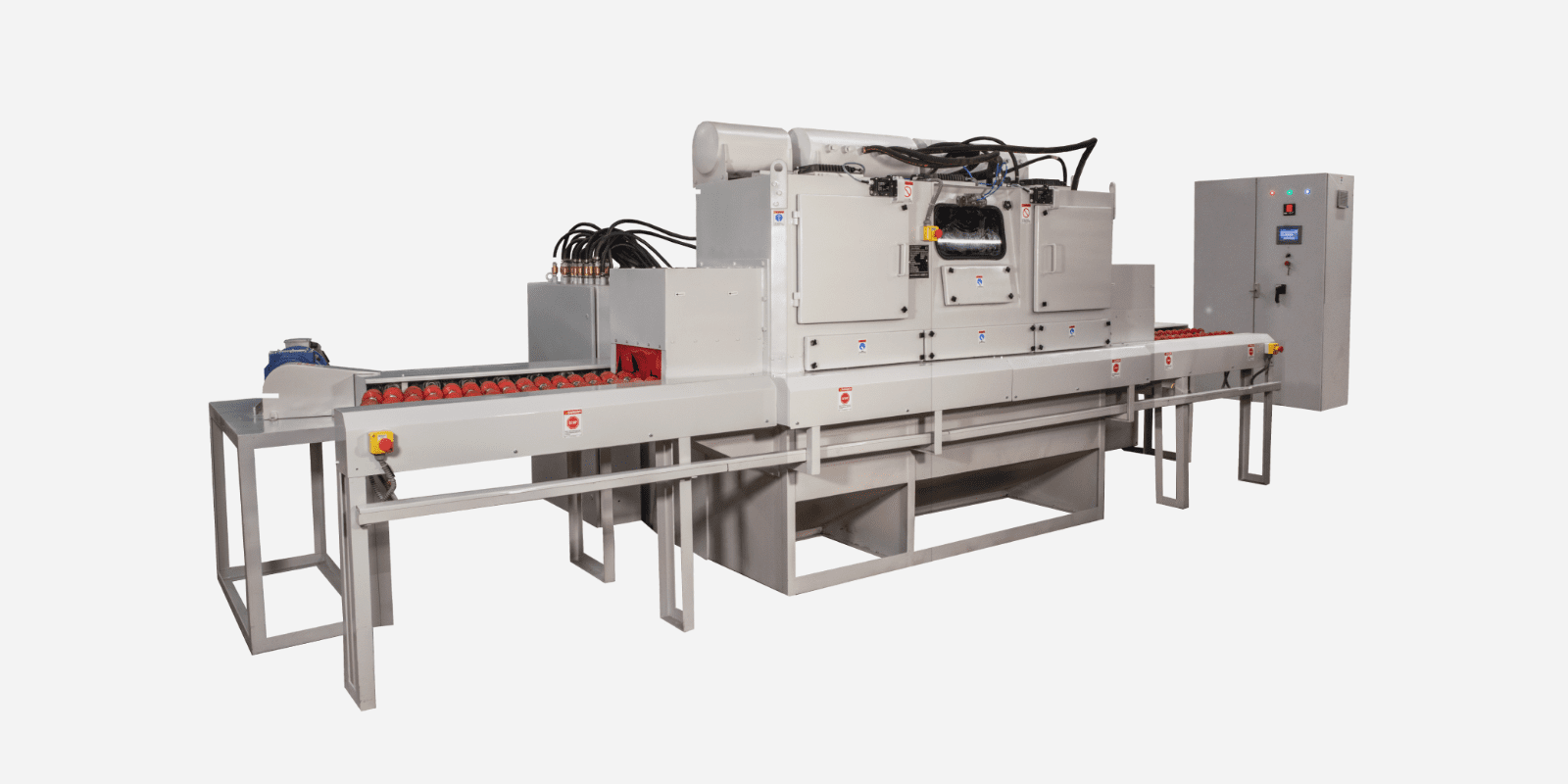

With a range of knowledge and expertise in the finishing industry, we provide our customers with high quality vapour blasting machines to help achieve the finishing results they require. This includes our AWB wet blasting range, which has been ergonomically designed for easy operation in sitting or standing position, for cleaning, descaling, deburring, roughening, oil or grease removal, die cleaning, perfect for all kinds of inert abrasives.

Alongside this range, we also offer an automated system for blasting of shafts before coating. This helps maintain an efficient system, consistent finish, fast throughput rate and much more.

To learn more about our vapour blasting machines and our specialist support services, download our brochure or get in touch with us, to start achieving great finishing results.

FAQs

What is the difference between vapour blasting and sand blasting?

While both blasting processes are similar, vapour blasting requires one extra step of adding water. The water, however, reduces dust and results in a more even finish. Sand blasting has the advantage of being a powerful option for finishing tougher materials.

Does vapour blasting remove metal?

Vapour blasting uses water and mildly abrasive media to clean metal surfaces without actually wearing away any of the metal. Discover our range of vapour blasting machines.

What media is used in vapour blasting?

Any type of blast media can be used, though glass beads, or a mix of sodium bicarbonate and fine glass beads are normally used for wet blasting inside a blast cabinet. For outdoor wet blasting, crushed glass, Green Diamond nickel slag, or copper slag may be used.