In the ever-evolving landscape of surface finishing, ActOn Finishing has once again taken a bold step forward by launching a new range of sand blasting cabinets, the NF series. With a reputation for delivering cutting-edge solutions, ActOn Finishing brings a new era of precision, efficiency, and versatility to the UK market. In this article, we will explore the significance of ActOn Finishing's NF Sand blasting Cabinets and the impact it will make in the thriving industrial and manufacturing sectors across the UK.

About the NF Sand Blasting Cabinet

As the demand for high-quality surface finishing solutions continues to grow, ActOn Finishing recognises the need for innovative and reliable equipment. The introduction of NF Sand Blasting Cabinet to the UK market is a strategic move aimed at meeting the diverse requirements of industries such as automotive, aerospace, metal fabrication, and more.

The NF Series includes two models: NF-MI9 and NF-MP9. While the NF-MI9 cabinet has been designed for suction blasting, the NF-MP9 cabinet is perfect for pressure blasting applications.

The versatile design permits both standing and sitting sandblasting, contingent on the model chosen. Additionally, the height is adjustable to cater to individuals of varying statures.

If needed, the media recovery unit can be detached from the enclosure. This configuration enables the placement of this component behind a partition. The notable advantage lies in the separation of the cyclone filling and dustbin emptying processes, taking place in a distinct room. This arrangement contributes to a healthier and cleaner work environment.

Key Benefits and Features

The NF Sand Blasting Cabinets are designed with meticulous attention to detail, allowing users to achieve the desired surface finish with unparalleled accuracy. Whether you are working on delicate components or rugged surfaces, the cabinets offer precise control over the blasting process. Some of the key benefits and features of this series include:

- Ergonomic working height.

- Cabinet is assembled into one compact unit.

- Cabinet and the filter unit are equipped with wheels for easy repositioning.

- Doors with safety switches.

- Both doors are designed with a sandwich construction for a sturdy construction and perfect sealing.

- With separate media system with filter.

- Cyclone ensures perfect blast media cleaning and a constant operating mixture.

- Ventilator with high extraction rate installed for a good view in the blast room.

- Fully automatic cleaning of filters.

- Blast process stops immediately after the foot pedal is released.

- PLC controlled.

- HEPA filter with an emission of <0,1 mg/m available.

- Maximum load 150 kg.

- Includes 20 recipes

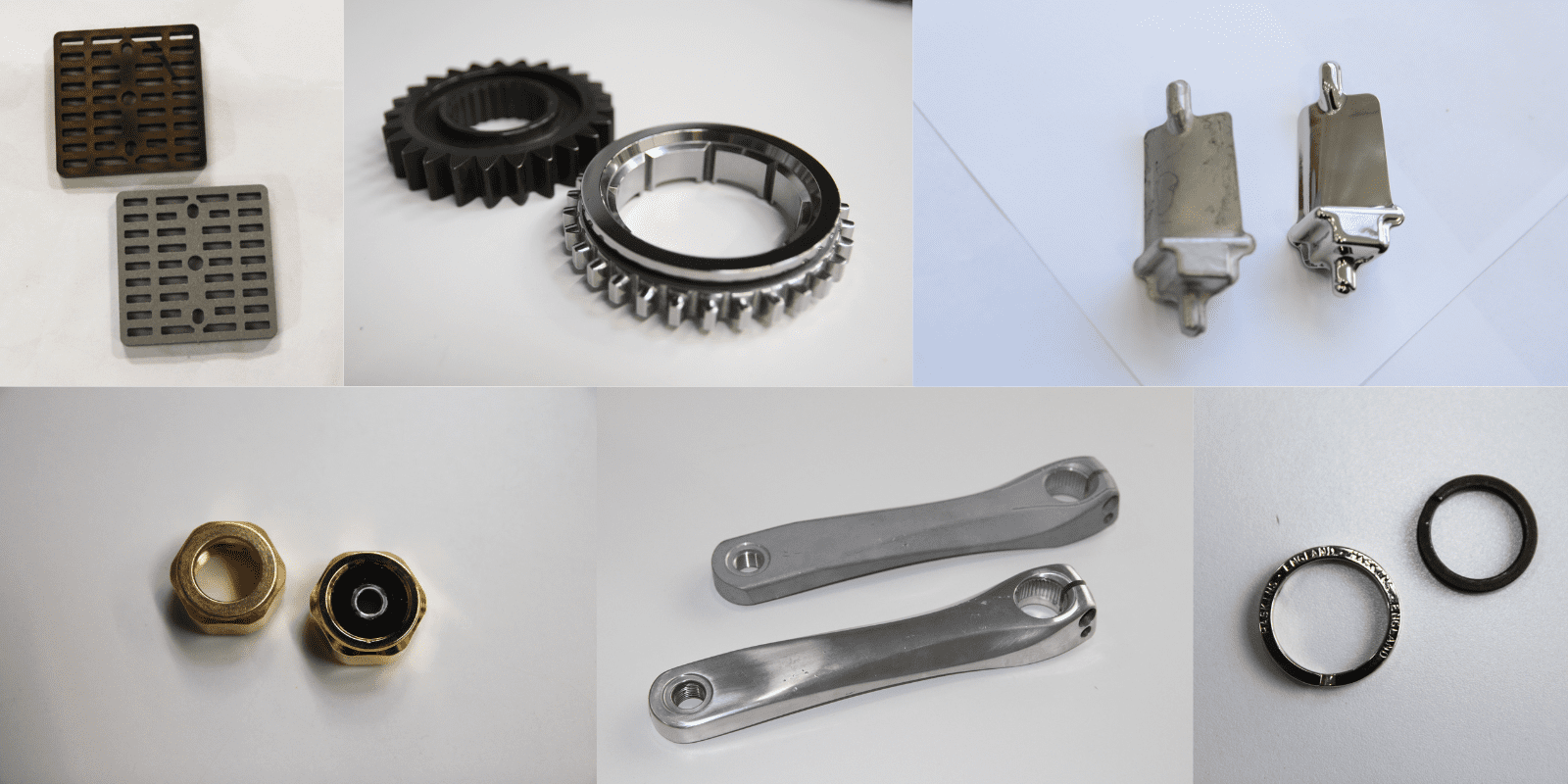

- Perfect for small parts.

- Easy load and unload.

- ATEX certified for processes class II 3/-D T125˚

- Easy to use and low maintenance costs.

- Reliable and repeatable finish each time.

Finishing Applications

These sand blasting cabinets are well-suited for finishing processes involving a variety of commonly used abrasives, including corundum, glass beads, ceramics, nut shells, plastic, and fine-grain sizes of stainless steel and steel. The NF cabinets, when paired with these diverse media options, facilitate a range of finishing applications, such as removing rust, paint, or residues resulting from corrosion, as well as effectively eliminating scratches or casting marks.

How it works?

The NF sand blasting cabinet has been designed to be easy to use:

- Component is placed in the cabinet through the left or right access door.

- The cabinet is moved to the proper working height.

- After closing the doors and adjusting of the blast pressure the foot pedal is operated.

- Exhaust fan and filter cleaning are started automatically.

Moreover for the NF-MP9 pressure blaster:

- The pop-up in the blast vessel closes, the dosage valve is opened and the blasting starts.

- Blast media, dust and contamination are sucked out of the blast chamber to the cyclone via the suction hose.

- The dust and contamination is removed from the blastingmedia in the cyclone.

- Dust is removed in the filter so that the exhausted air complies with NER.

- Dust collection is in a sealed dust bin.

- The filter is cleaned automatically via reverse air pulses.

For the NF-MI9 suction blaster:

- The blasting process is started.

- Blast media, dust and contamination are sucked out of the blast chamber to the cyclone via the suction hose.

- The dust and contamination is removed from the blasting media in the cyclone.

- Dust is removed in the filter so that the exhausted air complies with the NER.

- Dust collection is in a sealed dust bin.

- The filter is cleaned automatically via reverse air pulses.