At the end of a wet mass finishing process some components need to be dried, to avoid staining and corrosion. The question is how do you know if you need a Heated Air dryer or a Maizorb dryer? In this article, we will explain how to choose the dryer perfect for your finishing application.

Choosing the correct dryer depends on the finishing applications and part specification. Some components are too big to be dried in a portable drier, while others can’t be dried using agro media due to the risk of media lodgment, a heated air dyer being a better solution in this case.

For an easier way to determine which drier is best for your finishing needs, we have divided these machines in 2 categories:

- By drying requirements

- By size of batches/ parts to be processed

Dryers by Drying Requirements

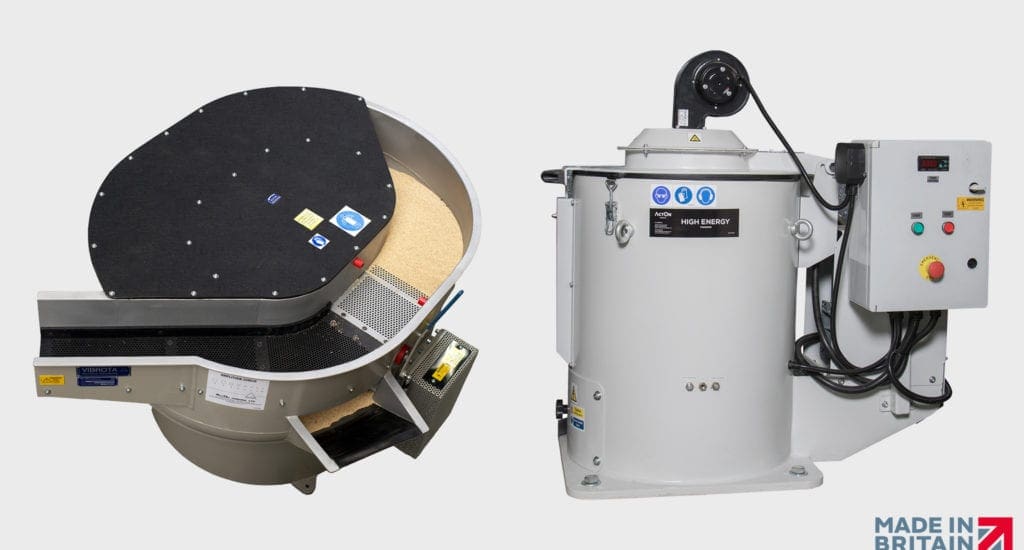

Components can be processed using a Maizorb dryer and via a Heated Air dryer. ActOn Finishing manufactures both types of dryers which can be used as part of a batch process or as a continuous process. These can be easily integrated with the ActOn vibratory finishing machines, for a complete finishing solution for your components.

Maizorb dryer

This range of machines normally use an agro media, such as Maizorb (corn cob) to dry the parts. The dryer’s heating elements heat the drying media which acts as an absorbent and removes any moisture from the parts. At ActOn Finishing we offer a wide range of Maizorb dryers, including:

VBD Series: Vibratory Finishing Dryers

This is a dryer with an elliptical shaped work chamber, a component separation system and a discharge facility. The shape of the drying chamber gives an extra drying area for the parts, thus minimising the drying time. Components are loaded in the dryer via a side loading chute. These are dried in the heated agro media and discharged at the end of the finishing process via a manual or pneumatically operated flap system. The machine has been built to guarantee that 100% of the parts are discharged at the end of the drying process.

The New VBD-P Range

This range has been developed for a drying application where 100% discharge of agro media and parts is required at the end of the finishing process. This simple to operate vibratory drier, has been designed to include an elliptical shaped work chamber, for extra drying area and minimum drying time.

Parts are loaded in the VBD-P drier via a loading chute. The machine includes a single speed motor with reverse flyweights, set to transfer the optimum amount of energy to produce a finish in the most efficient manner. The heating elements are used to heat the agro media (Maizorb), which acts as an absorbent and removes any moisture from the parts. At the end of the finishing process the pneumatically operated media door opens to allow 100% unload of media and parts.

To learn more about this dryer, check out the VBD-P Series Technical Flyer.

HD3000 Series

The HD3000 is a Maizorb dryer great for processing small batch works and delicate parts. The machine is mounted on castor wheels for ease of move. The discharge of parts at the end of the finishing process is made through the separation system. The machine is quiet in operation, and runs on a standard 16A socket, 1 phase, 240V AC supply thus making it a user-friendly kit for drying or polishing operation.

The HD3000 includes an UV lamp on the lid which automatically engages with the lid closed. This feature is great for sanitisation of cutlery, in the hospitality industry.

The New Portable Dryer: HT2D

This space saving machine is great for drying small and medium components and can be used as a batch type drying machine. Parts are manually inserted into the dryer’s preheated polyurethane lined work chamber and then dried using agro media. The dust free agro product, used in the HT2D, is an excellent moisture absorbent media which also produces a stain free polish effect on components.

The HT2D is very quiet in operation (noise level 65 db), includes single phase connectivity and has a drive system with sealed bearings for maintenance-free running. The design of the machine is compact; hence parts can be dried in an area where space is a restriction.

To learn more about this dryer, check out the HT2D Dryer Technical Flyer.

RD Series

The RD dryer is a rotary dryer that comprises of an inner rotating chamber where the

components get dried using appropriate agro media, which absorbs the moisture from the components. The inner barrel special design ensures parts travel from the feed end to the discharge end. Some of the advantages of this dryer are:

- 100% separation of components and media through a fixed sieve drum.

- Re-circulation of drying media with continuous output of parts;

- The agro media can be easily changed by running the inner chamber in the reverse direction.

For all the above Maizorb Dryers we recommend using of a Dust Extractor for Maize Application to collect the fine dust resulting from the drying process.

Heated Air Dryer

The geometry of some parts does not allow for these to be dried using agro media. Hence a heated air dryer could be the solution to avoid media lodgement in part’s holes or slots. Even though these dryers don’t use media to absorb the moisture from component, the process results in dry and clean parts every time. At ActOn Finishing we offer the following Heated Air Dryers:

CFD Series: Centrifugal Dryer

The Centrifugal Drier is best suited for drying large volumes of small components where the agro media cannot be used due to the risk of lodgment. This heated air dryer works with the circulation of open loop hot air. The processed parts are placed in a bowl which is rotated with an electrical motor and a belt. While the Stainless Steel bowl is turning the humidity and liquids are discharged from the bowl centrifugally. The heater assembled to the top of the cover is used to heat the air inside. The generated heated air dries the parts in a circular movement. The finished parts are stain free and protected against corrosion.

For all technical information on the CFD Series, read the Centrifugal Dryer technical flyer.

CD Series

The Conveyorised Electrically Heated Drying Oven is best suited for drying a variety of parts, which are large in nature or where the agro media cannot be used. Parts are loaded on the metal conveyor belt, which travels through the heated air dryer chamber and are collected at the discharge end. The CD Series includes a control cabinet oven, to accommodate all necessary signal lamps, emergency stop button, push buttons, fuses and the mains isolator.

Dryers by size of batches/ parts to be processed

Now that you know what drying requirements you have and what dryer fits these requirements, you have to consider the batch size you will process. Depending on the amount of parts you need to finish / week or / month you can choose between:

- Dryers that can process small to medium batches of parts such as ActOn Finishing HD3000 Series, the HT2D drier or the CD Series

- Dryers that allows you to process medium to large batches of parts such as the VBD Series, VBD-P Series, RD Series and the CD drier.

Also, you should consider the size of the part to be dried before choosing the drier. While a small drier such as the HD3000 Series, the HT2D drier or the CD Series will allow you to process small and delicate components; the VBD Series, VBD-P Series, RD Series and the CD drier are perfect for medium to large parts.

For technical information on ActOn Finishing Maizorb dryers and Heated Air dryers check our Mass Finishing Dryers web page.

If you would like to test which of these driers best suit your requirements, contact us at sales@acton-finishing.co.uk and we will carry out a free trial for you.