Choosing a surface finishing machine: CHE Finishing or Vibratory Finishing?

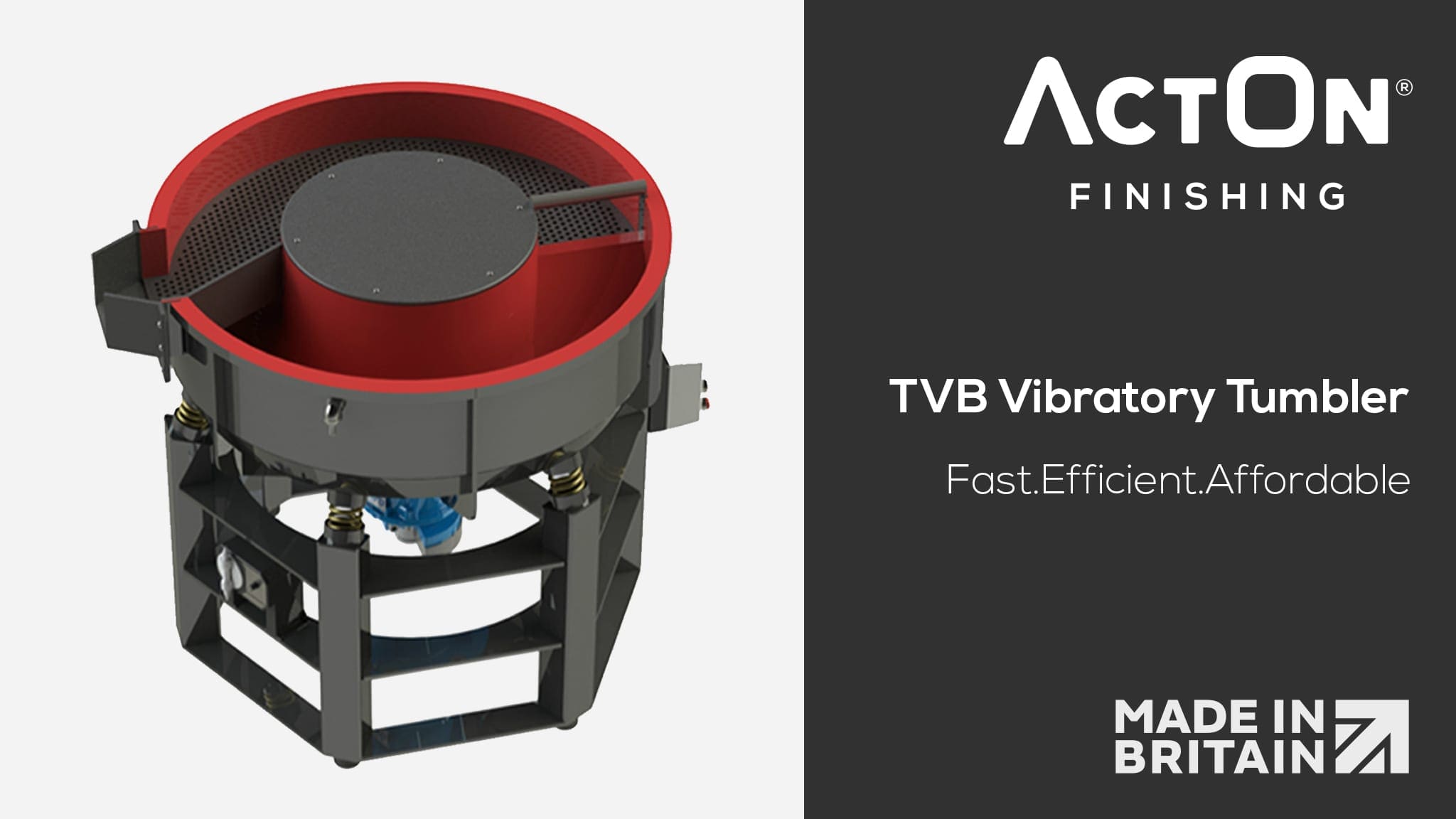

From medical implants to jewellery, the choice of what surface finishing machine to use will have an impact on both the process and the outcome. As the UK’s leading experts in designing and developing machinery and consumables for mass finishing applications, at ActOn Finishing we understand it can be confusing trying to understand the difference… Read more »

Read more