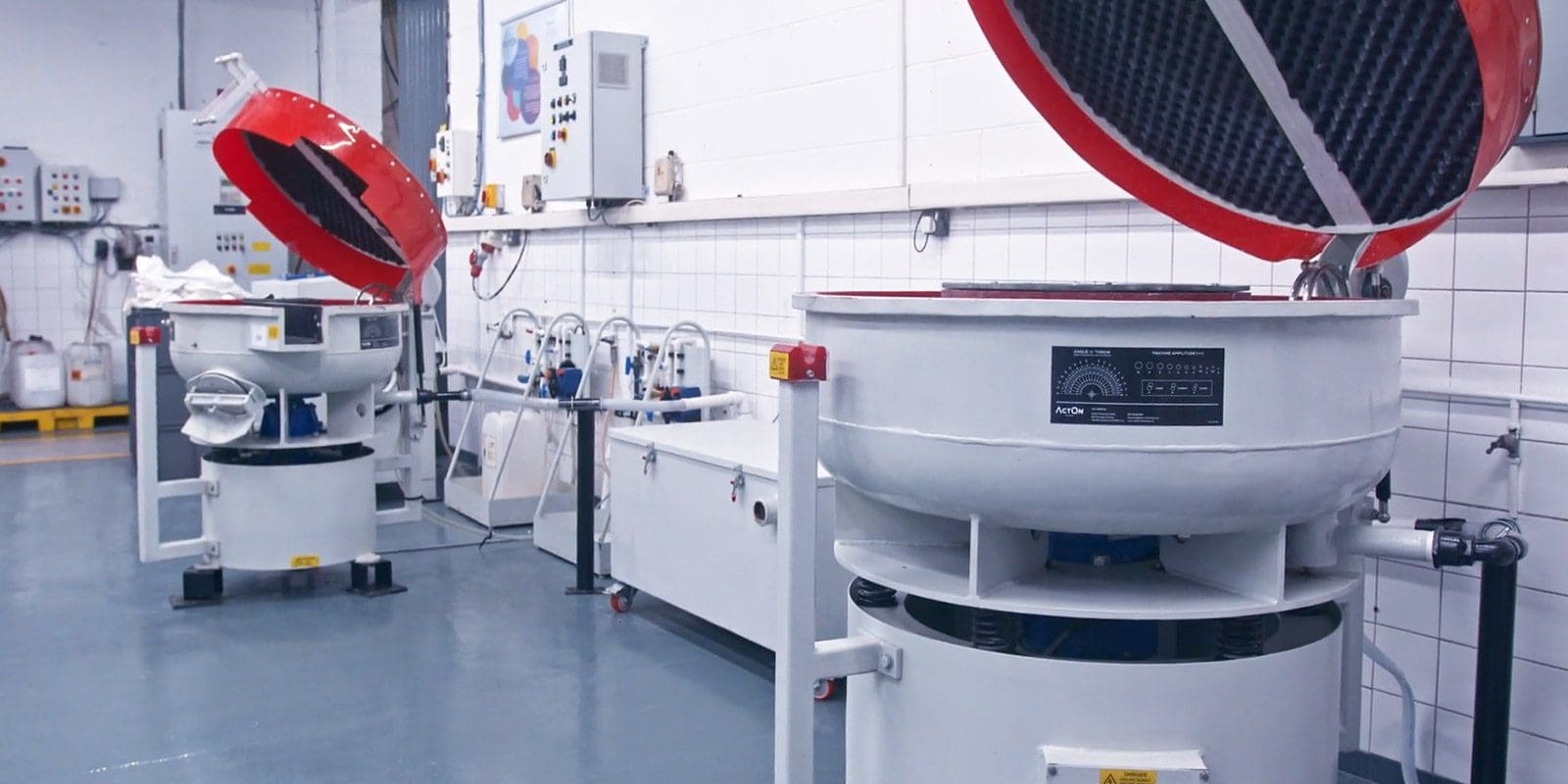

How does mobile shot blasting compare to other finishing processes?

When it comes to giving your surfaces that perfect finish, traditional methods can often fall short of the mark. That’s where mobile shot blasting can significantly improve your finishing process. In this blog, we’ll outline what the process entails, the benefits of mobile shot blasting and how it stacks up against other finishing processes. What… Read more »

Read more