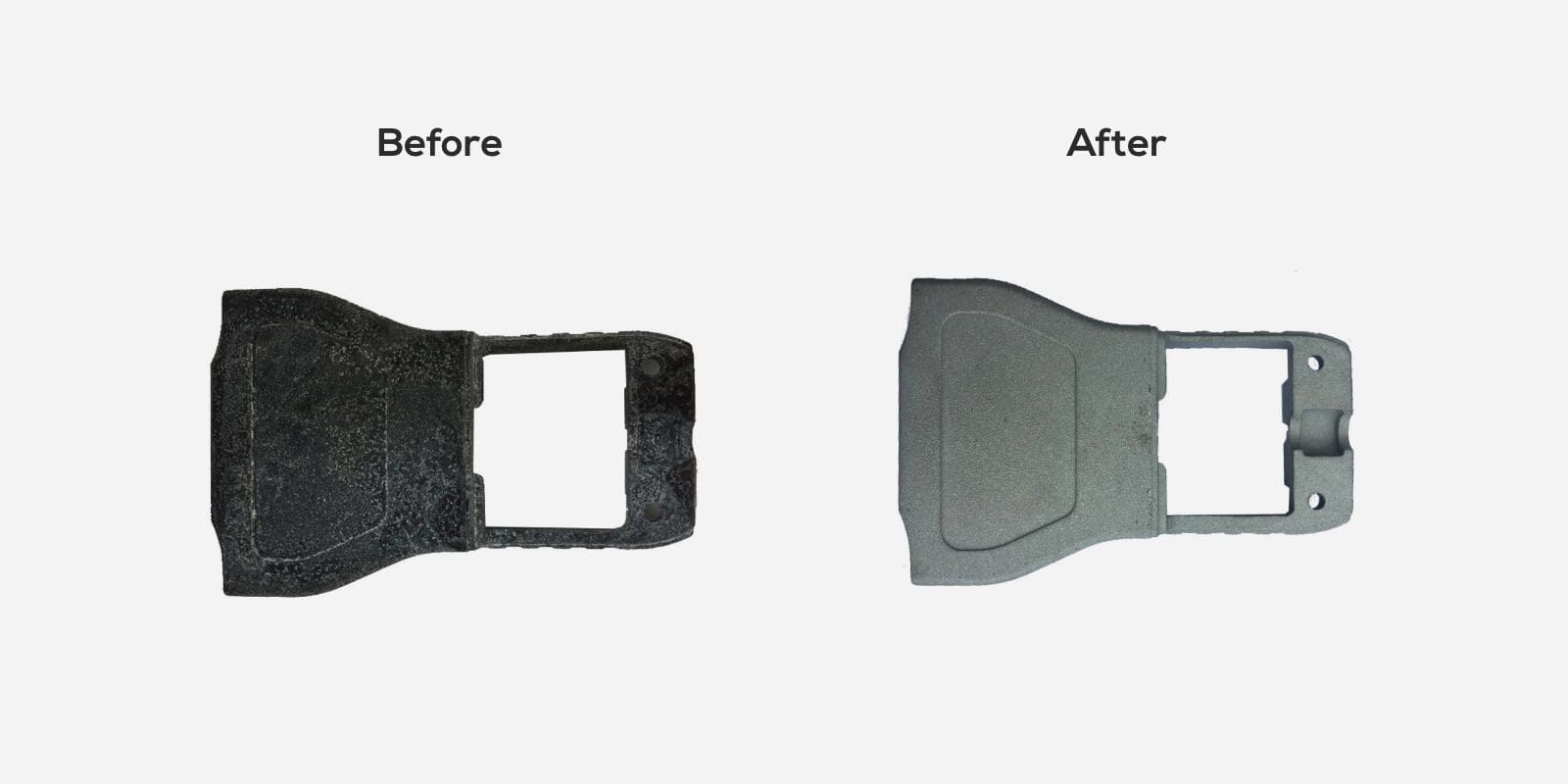

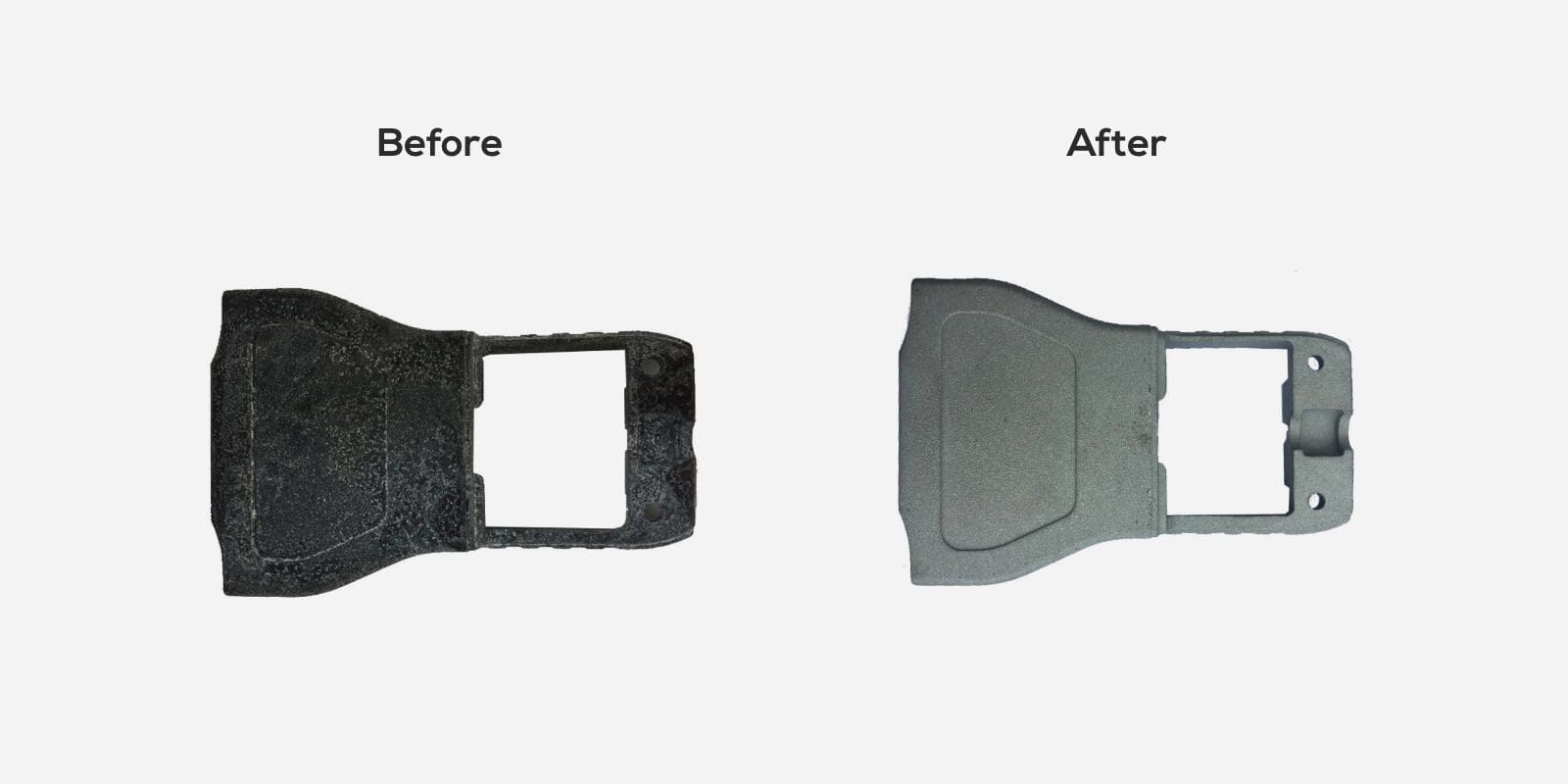

Shot blasting, also referred to as abrasive blasting, is a process used to clean metal surfaces, prepare parts for additional finishes and works to remove rust, slag or machining scales. The finishing effect all depends on several factors including the hardness and particle size of the media.

Most common technologies used for blasting are the wheelblasting systems and the shot blasting cabinets. In this article we’re going to unpack how these machines work and their advantages. By the end of this article you should be able to determine which method is better for your metal finishing requirements.

What is Shot blasting?

Shot blasting is the process of propelling abrasive media, by using compressed air, through nozzles and onto the surface of the component. It can be used to descale, remove corrosion, paint and rust, for smooth finishing, polishing or to strengthen the metal.

Depending on the finishing requirements, the shot blasting process can be wet or dry. To find out more about these blasting methods, check out our latest blog article.

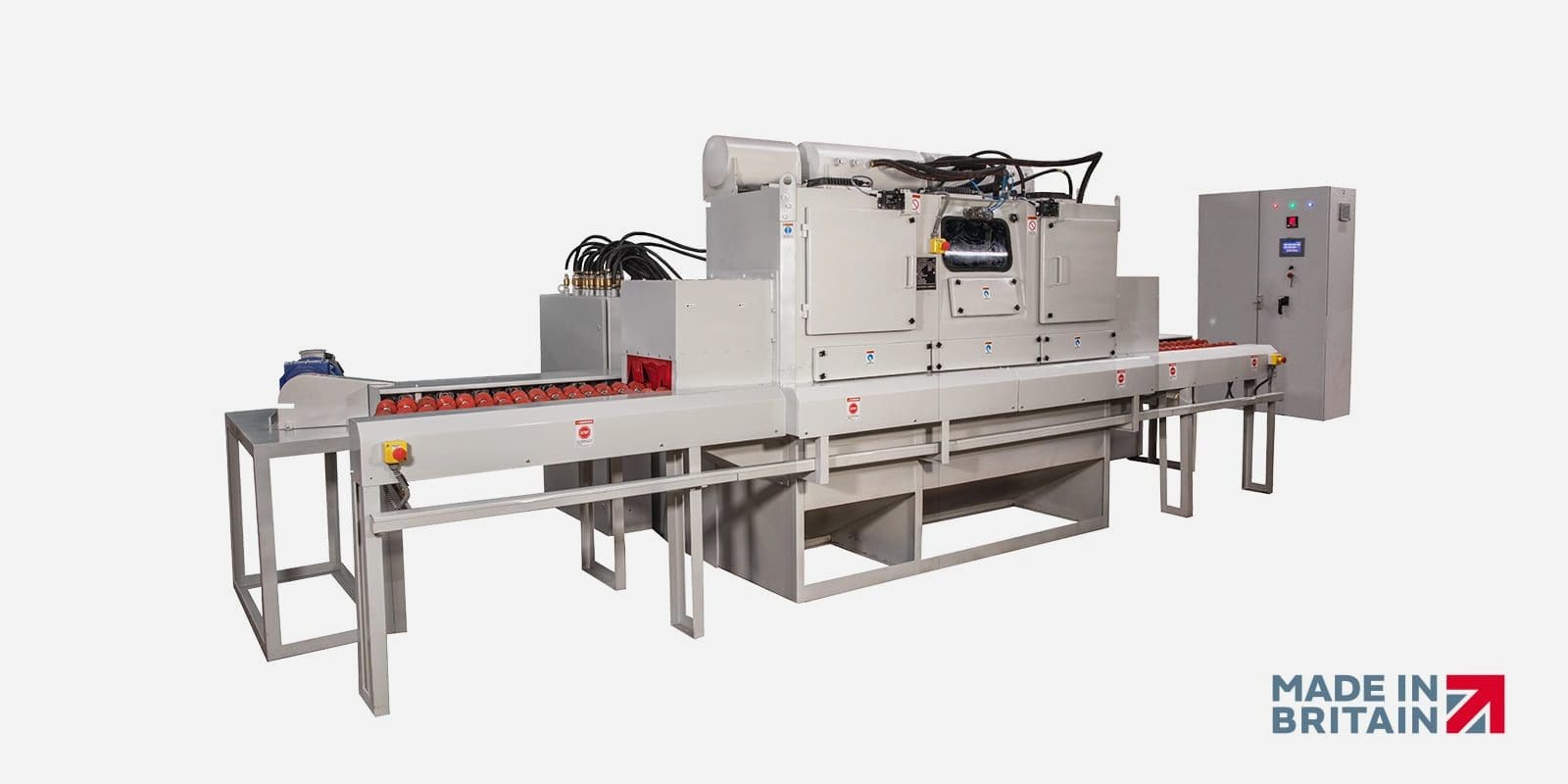

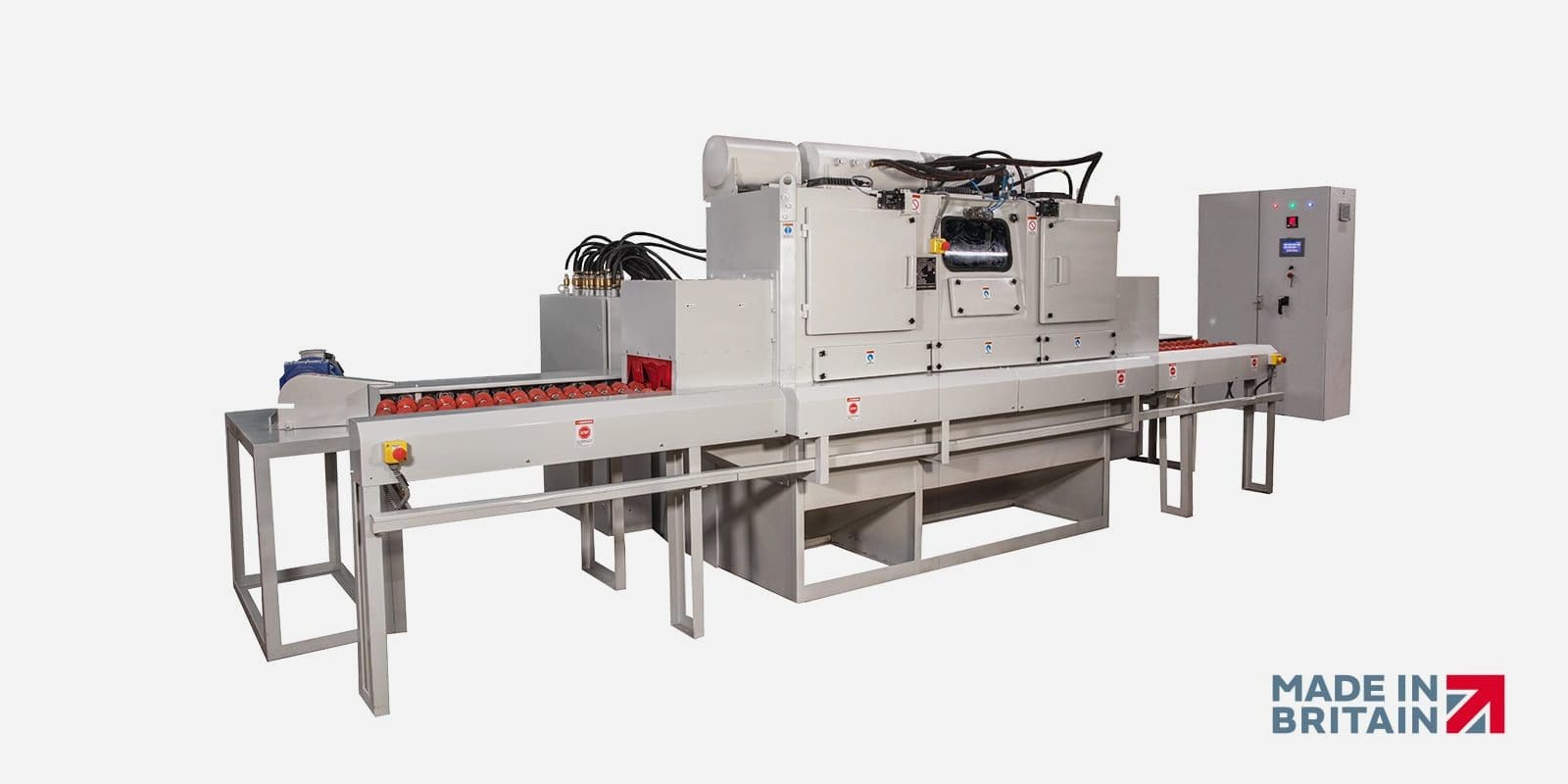

What is Wheelblasting?

Wheelblasting involves centrifugal force to propel media against a surface. A spinning wheel rotates at exceptional speeds to throw abrasives in a self-contained cage. This blasting method also has the ability to achieve various desired finishes, but without the use of air under high pressure.

What are the advantages of shot blasting?

One of the main advantages of shot blasting is the fact that it can be used for finishing individual parts of different shapes and sizes. Moreover, the blasting process can be done manually or automatically via a robot. Shot blasting is perfect for deep abrasive penetration on denser materials.

Corrosion can also be extremely hard to remove from certain metals, but it’s no challenge for the abrasive blasting method, which can strip even badly rusted beams and poles down to clean metal so they can be used again.

Shot blasting prepares the surface of metal quickly and effectively. The surface of metal that has been shot blasted will hold a paint layer or other type of coating far better than regular metal, providing an extremely strong bond and ensuring the coating will last for as long as possible.

Shot blasting has the ability to show up any surface defects that may have originally gone undetected. Any issues that may be present on the surface of the metal can easily be seen once you’ve used this method to clear it up. The abrasive media can also be useful in smoothing the surface out making it fit for the next layer you choose to put on it. Once a defect has been identified, it’s possible to aim the machine at that area to help level it out and allows you to investigate the severity of the problem, checking to see whether it runs any deeper.

Finally, shot blasting is environmentally friendly. Shot blasting eliminates the need for chemicals or harmful cleansing agents. It just uses the media to abrade the surface. This type of media blasting is great for those looking for a quick, powerful and effective finishing method.

Shot blasting advantages summed up:

- It is perfect for processing individual parts of different sizes, shapes and materials

- Removes corrosion

- Prepares the surface

- Shows up surface defects

- Environmentally friendly

What are the advantages of wheelblasting?

But probably one of the main advantages of wheelblasting is the fact that it can be used for finishing big components or large batches of parts. It can also be easily integrated in a production line by including roller conveyours and can be designed to suit your finishing applications.

This makes these machines more efficient, saving you both money and time.

Wheelblasting is also very flexible in terms of the components specifications and finishing application required. For example you can use:

- A Spinner Hanger Blast machine for fragile parts with complex shapes;

- A Tumble Steel Belt Blast machine for steel and brass forged parts, cast iron, aluminium, steel or brass castings & heat-treated components;

- A Continuous Feed Tube & Bar Blast system to surface finish pipes, bottles, gas cylinders or round bars;

- Or a Steel Tunnel Concrete WheelBlast machine to treat the surface of marble, granite, natural stone or concrete.

In addition, wheelblasting machines are relatively fast and efficient in preparing steel surfaces compared to other forms of abrasive blasting.

Wheelblasting advantages summed up:

- Can be integrated in your production line

- Speed

- Efficiency – Makes use of recyclable media for prolonged operation

- Flexibility in terms of force chosen

- Specifically great for large objects and steel surfaces

Which blasting method should I use?

There is no right or wrong answer to the question of whether shot blasting or wheelblasting blasting is better. There are many variables involved in making the decision of which method to use.

The best method depends on the surface you’re treating, the type of finish you are looking for, the size of parts and need of processing larger or smaller batches of components. Hence, we recommend shot blasting for finishing individual or smaller batches of parts and wheelblasting for manufacturers of medium to large forged and casted components, iron and aluminium foundries, automotive parts, metallic structures, pipes, bottles, cylindrical parts, round bars, torsion bars, gas cylinders and marble, granite, natural stone, concrete and aggregate blocks. Shot blasting is much more invasive, whereas wheelblasting is typically smoother and more efficient.

At ActOn Finishing we offer a range of shot blasting and wheelblasting systems to help our customers achieve the surface finish they need every time, with advanced machinery that will improve your media blasting experience. We can also help you decide what method will be better suited to you.

Download our brochures to find out more about our Wheelblasting and Shot blasting.