Want to find out what Wet blasting is? Put simply, it’s the use of an abrasive blasting media and water to achieve a desired finish on a chosen surface. It’s often compared to Dry blasting, which is a similar finishing method only without the added use of liquid.

In this article we’re going to answer the question ‘What is Wet blasting?’ and explain how it works, the differences between Wet and Dry blasting and the overall benefits of using Wet blasting for your finishing requirements.

What is Wet blasting and how does it work?

Wet blasting, also referred to as Vapour blasting, is an abrasive cleaning method that involves pressurised wet slurry which is applied to component surfaces for various cleaning or finishing effects. You most likely don’t just want to know what it is? But also how it works and what it can do, well the answer is quite a lot. The blast media that is used when wet blasting is moistened prior to impacting the surface, the slurry mixture is then sent to a nozzle/s where regulated compressed air is used to adjust the pressure of the slurry as it blasts the surface.

This method allows you to extensively clean, degrease, deburr and descale parts. This blasting method also removes paint, chemicals and oxidation and is perfect for high-precision composite etching for bonding.

Wet blasting vs Dry blasting: The Difference between the two finishing methods

Wet blasting is often compared to a similar finishing process called Dry blasting. The main difference between the two is in the name, one uses water or liquid, Wet blasting, and the other doesn’t, Dry blasting.

The mixing of liquid and abrasive media, which takes place in with the wet blasting process, means that the abrasive media particles hit the blasting material which may cause them to shatter. Whilst this happens in both Wet and Dry blasting, the difference is that due to the static charge in Dry blasting it can cause sparks. This possibility is eliminated when adding liquid, as it diffuses the dust produced during the process making it a safer process overall.

When asking the question, it’s helpful to remember the finish it can provide too. Where Dry blasting is much more aggressive and can cause unwanted damage, the use of water with Wet blasting almost acts as a cushion which helps push the particles across the surface, resulting in a finer satin or polished texture. Due to this, it’s also very effective at removing coatings without damaging underlying material, unlike the harsher Dry blasting process.

What are the benefits of Wet blasting?

As mentioned above, the Wet blasting process is less abrasive on materials and ensures a polished finish, without any static charges or sparks. There’s also the noticeable dust reduction when opting to use this, as the water stops abrasive dust particles floating around and impacting the finish – this is particularly great for open environments and improving your equipment life as the process is not as harsh on equipment.

Another benefit is its sustainability and that it’s an all in one step process. You’re able to strip the surface and clean it at the same time meaning you won’t need to spend any extra time, money or resources on a separate rinsing process to remove media fragments.

Wet blasting is perfect for those looking for affordable, quick and easy precise finishing results and it’s safe for your sensitive materials.

ActOn solutions for wet blasting

ECO AWB1100 Wet Blasting Cabinet is our Economic Wet blasting cabinet and has been designed for easy operation whether you’re sitting or standing. The cabinet is great for cleaning, descaling, deburring, roughening, oil or grease removal, and die cleaning.

Its benefits & features include:

- A pressure regulator to control air flow.

- Rapid and efficient blasting.

- Internal blast chamber lined with plastic sheets for protection.

- Blasting process free of interruption.

- 1 large stainless steel swing door with seals, gutter and safety switch arrangement.

- British built, high-quality blasting cabinet.

- Electronically operated foot pedal.

Download our brochure to find out more about our ECO AWB1100 Wet Blasting Cabinet.

Premium NP Wet Blasting Cabinets is our cabinet that is equipped with a special pump that achieves a constant flow of blast media and water to the blast nozzle. The media and water is mixed with pressurised air to add extra power and speed to the mix. These machines can be used with all kinds of inert abrasives.

Its benefits & features include:

- Dust-free blast process.

- De-grease and blast in one process.

- Almost zero impression of the abrasive surface.

Download our brochure to find out more about our Premium NP Wet Blasting Cabinet.

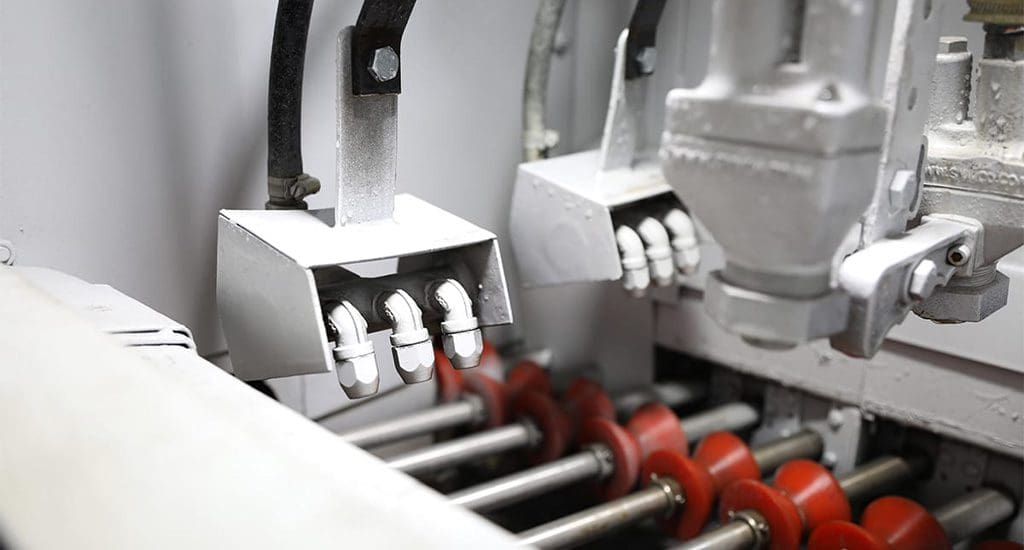

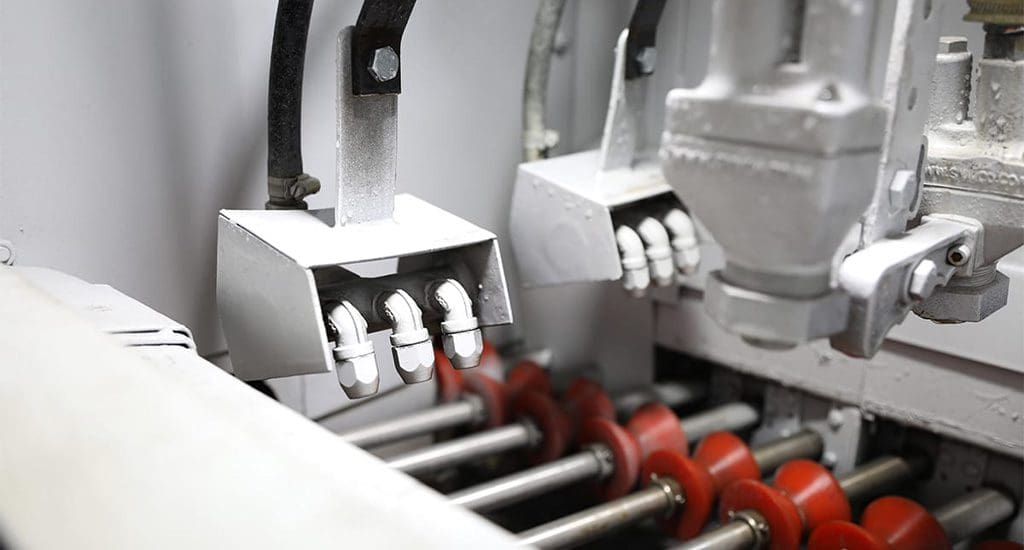

ActOn Automated Wet Blasting Machine has been designed by ActOn for blasting of shafts prior to coating. Parts travel through the blast chamber, enter the water wash chamber and are then air dried before exiting.

Its benefits & features include:

- Consistent finish across all parts.

- Fully automated system.

- Fast throughput rate.

- British built high-quality vibratory bowls.

- Efficient in operation.

Download our brochure to find out more about our ActOn Automated Wet Blasting Machine.

Have we helped answer the ‘What is Wet blasting?’ question? We hope so, now you understand the process and the benefits the finishing process can have on your parts. Take a look at our Wet blasting machines and make sure you download our brochures to find the right Wet blasting machine for you.