When it comes to finishing your parts, surface finishing is a crucial end process. But with so many surface finishing technologies and methods to choose from, and the different surface finish and flatness achievable depending on the method you choose, it’s important to choose the right one.

In this blog we explore the different types of surface finishing technologies available and what they do, so you can feel confident you’re choosing the right process type and method for your parts.

Lapping Process – ideal for accuracy, correction or refinement

Lapping is a surface finishing process that is carried out using loose abrasives. In the lapping process, smoothing is achieved by the abrasive grains – these are supported by the lap, which acts as a cutting tool shank. And, as it doesn’t require the use of holding devices, there’s no work-piece distortion.

Lapping is ideal if you want surface finishing processes such as an extreme accuracy of dimensions, refinement of surface finish, correction of minor imperfections of shape or if you need to produce a close fit between mating surfaces.

Polishing Process – ideal for surface finishes

Polishing is generally used to generate a reflective surface and is usually carried out after a lapping operation. This means that using the polishing process is ideal if you want to improve appearances as the method delivers a fantastic surface finish.

You can also use the polishing process for sealing surfaces, optically measuring flatness, improving the optical qualities of materials and for improving electrical contact.

Chemical Mechanical Polishing (CMP) – ideal for smoothing surfaces

Often referred to as CMP Polishing, this surface finishing process sees the top surface of a wafer being polished with a slurry containing an abrasive grit, suspended within reactive chemical agents. Highly versatile, CMP is designed for use in polishing applications where geometric precision and surface quality are of paramount importance.

By using a combination of chemical etching and free abrasive polishing, chemical mechanical polishing will help smooth surfaces as the polishing action is partly mechanical and partly chemical. This also means that the mechanical element of the process applies downward pressure while the chemical reaction that takes place increases the material removal rate – and this is usually tailored to suit the type of material being processed.

This process is also commonly used if scratch free microscopic images are needed (such metallurgical samples for micro hardness testing) or if there is a need for a very low Ra.

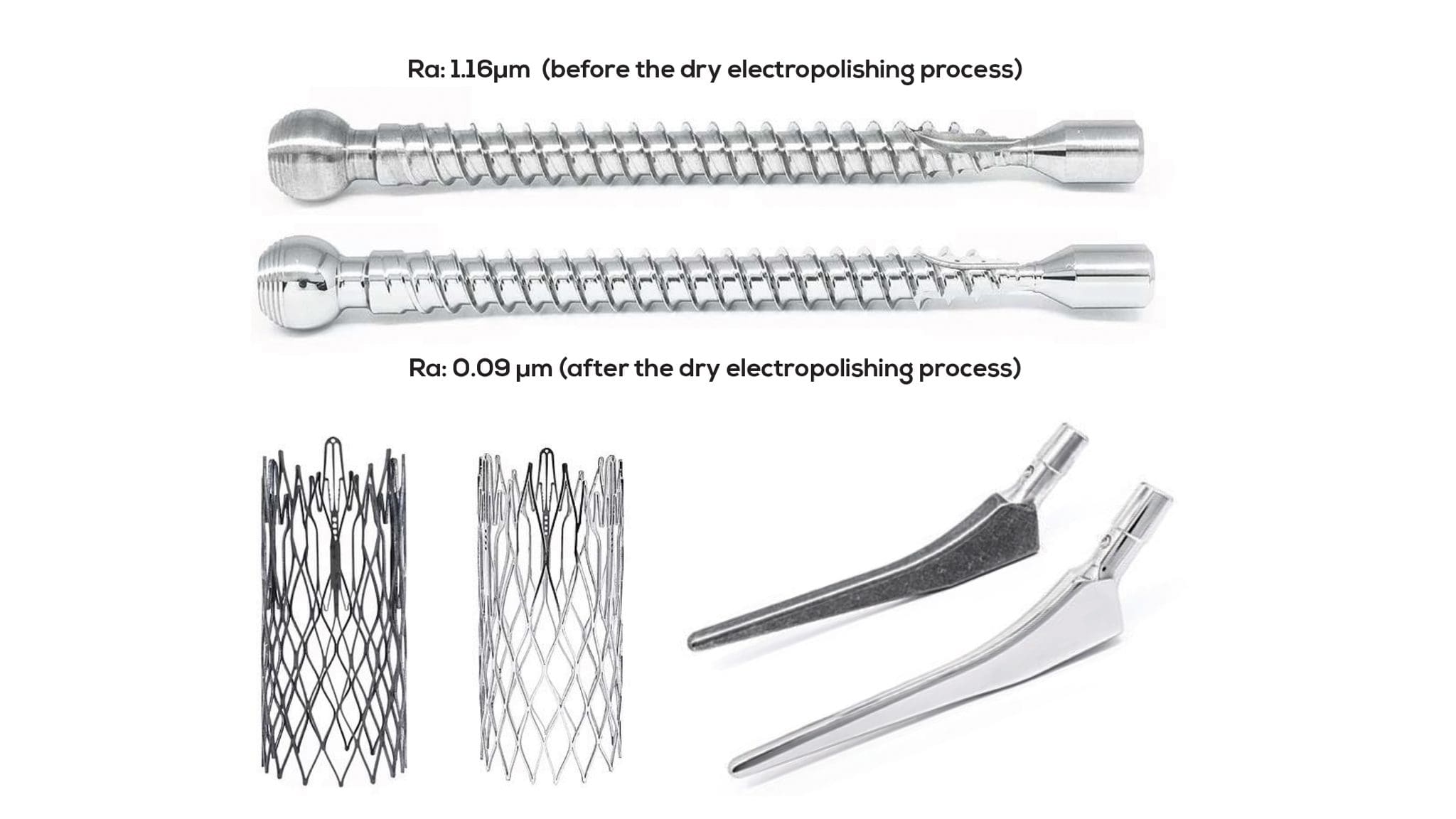

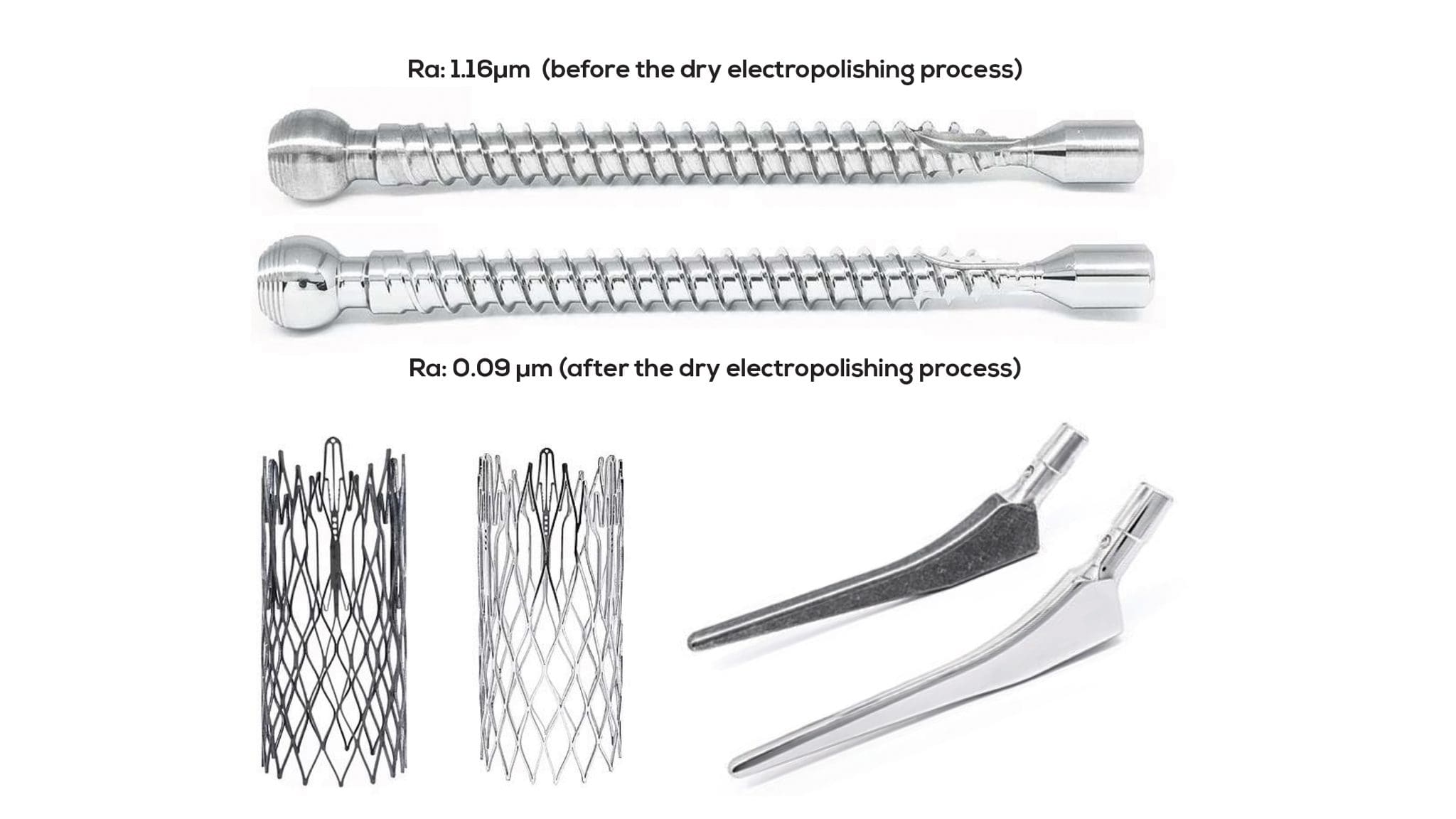

Dry Electropolishing – ideal for delivering mirror-like finishes

By preserving the geometry of the cast or machined component without rounding edges, Dry Electropolishing can remove grinding patterns for fantastic, mirror-like finishes.

Effectively reducing roughness, this surface finishing option can also achieve complex geometries without any micro-scratches on the surface – all whilst maintaining component tolerances.

Centrifugal Polishing – ideal for a rapid cutting action

A rapid cutting action is produced the turret and the barrels rotate at high speed in opposing directions and the resultant centrifugal force increases the weight of the abrasive media in the barrels which slides against the components, also in the barrels.

The drive mechanism of a Centrifugal Polishing machine is also designed to produce high ‘G’ forces of 5-25 times than normal gravity with 3 or 4 hexagonal/circular barrels mounted on a turret, which generates a very high gravitational force. Centrifugal polishing can be 10 times faster than vibratory finishing, producing superior finishes such as mirror finishing, reducing significant surface roughness or removing surface defects.

Vibratory Finishing – ideal for deburring and brightening

Vibratory finishing is one of the most common types of mass surface finishing processes that is used to deburr, radius, descale, burnish, clean, and brighten small workpieces.

For this type of operation, specially shaped pellets of media are used and placed into the vibratory tumbler. These are then moved in a circular motion whereby the media will grind against the part to get the desired finish.

Drag Finishing – ideal for complex parts with high specs

Drag finishing is a specialised version of vibratory finishing with the main difference being that drag finishing is typically for complex parts with high surface finishing specifications. Its applications range from high-gloss polishing, degreasing and descaling of metal components.

The parts that require deburring and finishing are mechanically dragged through the media while attached to fixtures, preventing the parts from contacting one another.

Grinding Process – ideal for surface finishing in hard materials

Grinding is an abrasive machining process that uses coarser abrasive material. It’s specially indicated for surface finishing in hard materials in order to obtain low surface roughness and achieve tight tolerances.

There are numerous surface finishing methods, with different end results depending on the finish you want to achieve. If you require more information or guidance on what to choose, please get in touch, and one of our customer service team will be happy to help.

FAQs

What is a vibratory finishing machine?

As a common finishing method in the manufacturing industry, vibratory finishing is an efficient process used to optimise all types of small products and parts. Our vibratory finishing machines help you clean and deburr products at a faster pace.

What is vibratory deburring?

Vibratory deburring removes the rough edges from parts and enables them to fit together more efficiently. This leads to fewer part rejections as well as improved safety. In addition, deburring is an important step in preparing parts for painting.

How does vibratory polishing work?

In this stage a combination of media, parts and compounds are placed in a vibrating machine. The vibrations cause the contents to move in a circular motion and the media to grind against the part to get the desired finish.

What is a tumbling barrel?

Barrel finishing, also known as barrel tumbling or vibratory finishing, is a surface improving operation in which a mixture of parts, media and compounds are placed in a six- or eight-sided barrel and rotated at a predetermined speed for the purpose of rounding corners, deburring, grinding, descaling, deflashing, improving surface finish and much more.

What are the different types of finishing?

There are several types of metal finishing such as metal plating, chemical finishing or coating, grinding, buffing, electroplating, and sandblasting. Each process has basic steps with all processes beginning with surface preparation. Metal finishing processes can include anything from technical processes to buffers.