-

-

-

- About

- Industries

-

Sub-Contracting

-

- Consumables

-

Cleaning

-

- All Ultrasonic Machines

- TT Standard Ultrasonic Series

- LT Pro Laboratory Ultrasonic Cleaning Machines

- MOT Automotive Ultrasonic Cleaning Machines

- One Tank Industrial Ultrasonic Cleaning Equipment

- Manual Multistage Ultrasonic Cleaning Equipment

- Multistage Automatic Ultrasonic Cleaning Machine

- Ultrasonic Generators

- Ultrasonic Cleaner Solution

-

-

Blasting & Peening

-

- All Shot Blasting Machines

- Powertrack Junior Portable Blast System

- Powertrack Portable Blast System

- ActOn Mobile Shot Blasting Room

- ECO Shot Blasting Machines

- Premium DI Suction Blasting Machines

- Premium DP Pressure Blasting Cabinets

- AWB Wet Blasting Cabinet

- Premium NP Wet Blasting Cabinets

- Automated Wet Blasting Machine

- NF Sandblasting Cabinets

- DLyte eBlast – Electro Shot Blaster

- AM Shot Peening and Blasting Series

- Automated Shot Blasting Equipment

- All Wheel Blasting Machines

- Spinner Hanger Blast Machine

- Tumble Rubber Belt Shot Blasting Machine

- Tumble Steel Belt Shot Blasting Machine

- Wire Mesh Belt Shot Blasting Machine

- Continuous Feed Overhead Rail Blasting Machine

- Roller Conveyor Blast Machine

- Continuous Feed Tube & Bar Blast Cleaning Machine

- Rotary Table Shot Blasting Machine

- Tunnel Concrete Shot Blast Machine

-

-

Surface Finishing

-

-

Surface Finishing

- All Mass Finishing Machines

- Vibratory Bowl Machines

- Vibratory Trough Machines

- Dual Finishing Machines

- Dryers

- Centrifugal High Energy Machines

- Disc Finishing Machines

- LE30 Rotary Barrel Machine

- Wheel Polishing Machine

- Automation for Mass Finishing

- Mass Finishing Accessories

- All Vibratory Machines

- Vibratory Dual Machines

- Vibratory Consumables

- Vibratory Bowl Machines

- Vibratory Trough Machines

- Dlyte Technology

- Waste Water Treatment

- REFURBISHED MACHINES

-

Blasting & Peening

- All Shot Blasting Machines

- Powertrack Junior Portable Blast System

- Powertrack Portable Blast System

- ActOn Mobile Shot Blasting Room

- ECO Shot Blasting Machines

- Premium DI Suction Blasting Machines

- Premium DP Pressure Blasting Cabinets

- AWB Wet Blasting Cabinet

- Premium NP Wet Blasting Cabinets

- Automated Wet Blasting Machine

- NF Sandblasting Cabinets

- DLyte eBlast – Electro Shot Blaster

- AM Shot Peening and Blasting Series

- Automated Shot Blasting Equipment

- All Wheel Blasting Machines

- Spinner Hanger Blast Machine

- Tumble Rubber Belt Shot Blasting Machine

- Tumble Steel Belt Shot Blasting Machine

- Wire Mesh Belt Shot Blasting Machine

- Continuous Feed Overhead Rail Blasting Machine

- Roller Conveyor Blast Machine

- Continuous Feed Tube & Bar Blast Cleaning Machine

- Rotary Table Shot Blasting Machine

- Tunnel Concrete Shot Blast Machine

- Refurbished Machines

-

Cleaning

- All Ultrasonic Machines

- TT Standard Ultrasonic Series

- LT Pro Laboratory Ultrasonic Cleaning Machines

- MOT Automotive Ultrasonic Cleaning Machines

- One Tank Industrial Ultrasonic Cleaning Equipment

- Manual Multistage Ultrasonic Cleaning Equipment

- Multistage Automatic Ultrasonic Cleaning Machine

- Ultrasonic Generators

- Ultrasonic Cleaner Solution

- Vibratory Finishing Machines

- Consumables

- Sub-Contracting

- Industries

- About

- Free Trial

- Contact us

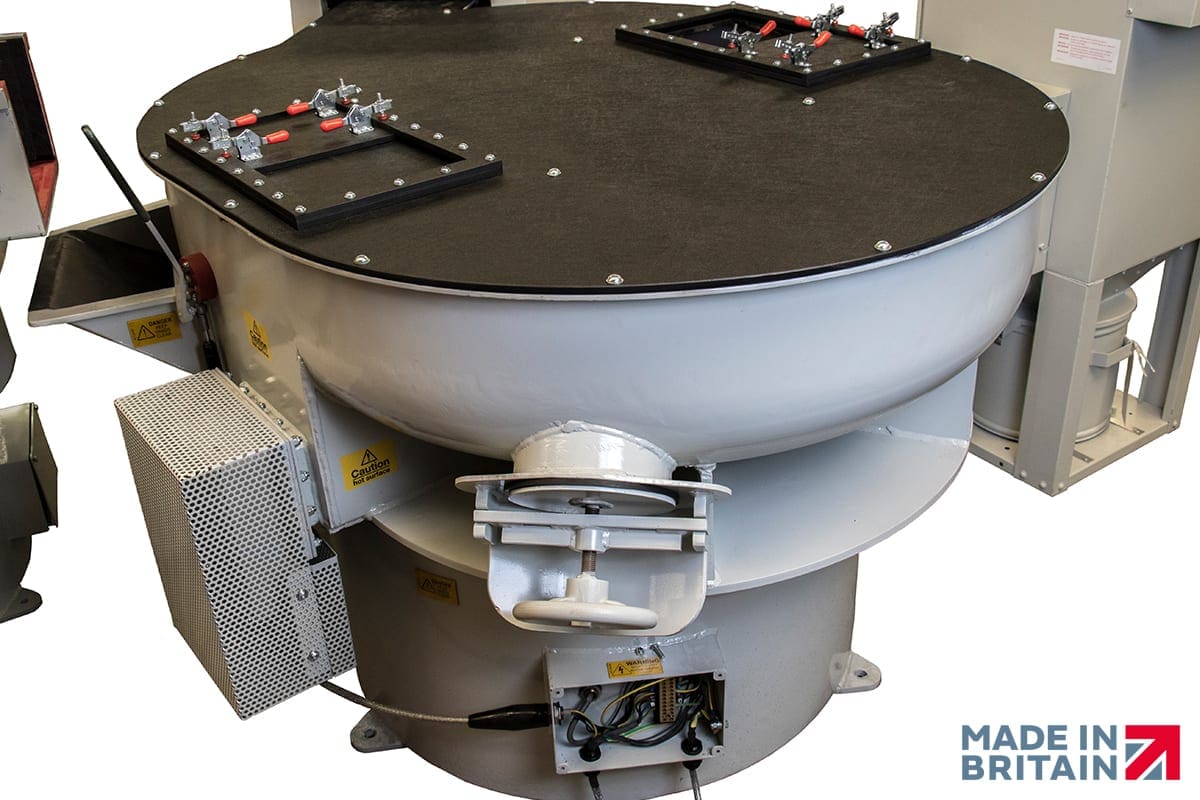

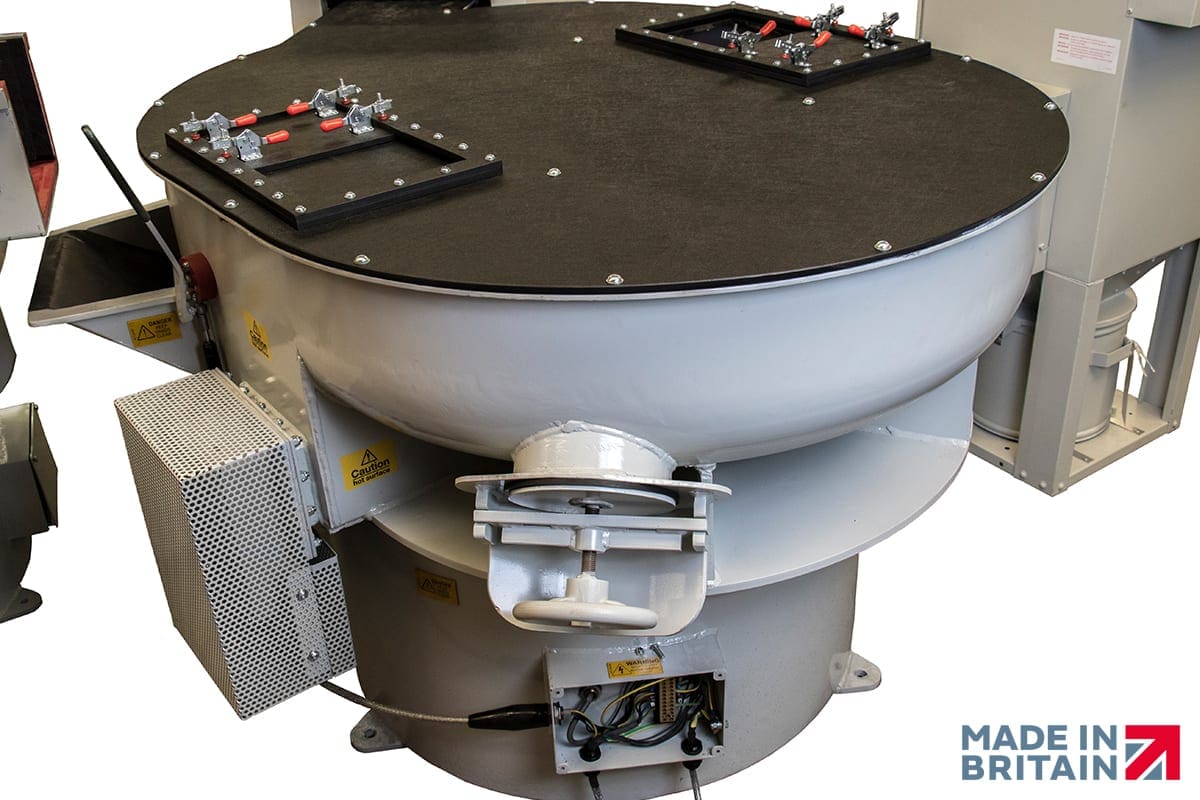

Mass Finishing Dryers

From classic size to bespoke specifications, our unique mass finishing dryers provide solutions for every one of your drying requirements. Hence you can choose between a Conveyorised Electrically Heated Drying Oven, a Vibratory Finishing Dryer, a Rotary Dryer, or a Centrifugal Dryer. When there is a space restriction and you need to dry small and medium sized components consider using a smaller finishing dryer such as ActOn’s HD3000 or HT2D dryer.

Our dryers can be easily integrated with the ActOn vibratory finishing machines, thus offering a complete finishing solution for your components.

Get a quoteKey Features

- Metal spun process chamber

- Easily customisable to suit customer requirements

- Our durable reinforced screens can be used for heavier parts

- Compact design

- Quick to install and easy to maintain

DISCOVER OUR CENTRIFUGAL DRIVER

Key Benefits

- British built, high-quality product

- Efficient in operation

- Quiet in operation

- Process results in dry and clean parts

- Operator friendly controls

- Low maintenance

- Manual / Auto functionality

- Customised to suit user applications

DISCOVER OUR CENTRIFUGAL DRIVER

Specifications

| Series | Model | Capacity | Overall dimensions in mm / inch | Process Chamber Dimensions in mm/ inch after lining | Max Motor Rating (kW) | Number of Heaters | Total Heater Rating (kW) | |||||

| Cu. Ft. | Litres | Length | Width | Height | Length | Width | Height | |||||

| HT2D | HT2D | 2 | 60 | 825/ 32.5 | 725/ 28.5 | 971/ 38.2 | 575/ 22.6 | 395/ 15.5 | 368/ 14.5 | 0.34 (1500 rpm) 0.50 (3000 rpm) | 3 | 0.3 |

| VBD Series | VBD3 | 3 | 85 | 1200 / 47.2 | 950 / 37.4 | 980 / 38.6 | 280 / 11 | 300 / 11.8 | 1.2 | 2 | 2 | |

| VBD6 | 6 | 170 | 1650 / 64.9 | 1315 / 51.7 | 1000 / 39.4 | 260 / 10.2 | 335 / 13.2 | 2.2 | 3 | 3 | ||

| VBD12 | 12 | 340 | 2000 / 78.7 | 1620 / 63.7 | 980 / 38.5 | 365 / 14.4 | 370 / 14.6 | 4 | 3 | 3 | ||

| VBD24 | 24 | 680 | 2615 / 102.9 | 1930 / 75.9 | 1150 / 45.3 | 392 / 15.4 | 425 / 16.7 | 7 | 6 | 6 | ||

| TU10D | TU10D | 10 | 283 | 1590/62.6 | 1000/39.37 | 1275/50.2 | 1200/47.2 | 460/18.1 | 565/22.2 | 2.2 | 2 | 2 |

| Notes: | ||||||||||||

| 1. Sizes indicated above are standard. Custom sizes can be manufactured to suit specific applications. Dimensions are subject to change due to design improvements. | ||||||||||||

| 2. Our range of dryers includes the following series: CD, HD3000, HT2D, VBD, TU10D, CFD & RD series. Please check our Vibratory Finishing brochure for further technical information on all our dryers. | ||||||||||||