At ActOn Finishing, we understand the importance of having the right finishing equipment to save you time and money.

Just by moving from manual finishing to vibratory finishing you will be able to cut costs and reduce delays by decreasing processing times. Vibratory finishing not only produces a consistent finish (eliminating the need to waste time on reworks) but also saves you money by avoiding high part reject rates.

To help you find the right machine for your part and budget, we’ve taken a closer look at the most affordable finishing solutions out there in the market right now.

British made Vibratory Bowls

All of ActOn’s vibratory finishing machines are designed and manufactured in the UK. They are renowned to be of high quality and high reliability.

The extremely robust Bench Mounted Series

These machines are ideally suited for small batch works and are capable of deburring, burnishing, radiusing, descaling, polishing, cleaning and surface improvement. The bowl is cast as a single moulding and is extremely robust in its construction. The machine operates via a standard DOL starter and is easy to operate.

The modern and versatile TVB Series

The TVB series is a compact, modern and versatile finishing machine that allows OEMs and subcontractors to minimise their investment, whilst enjoying the extra benefits and features of a vibratory machine. This machine offers 40% faster processing times than current models in the market and its optimised design reduces material wastage and manufacturing time.

Vibratory Troughs Range: The user friendly HT Series

Generally quiet in operation, these machines are ideally suited for small batch works and delicate components. The machines are mounted on castor wheels meaning it can be moved with ease and it’s a very user friendly kit for deburring or burnishing operations due to running on a standard 16A socket, 1 phase, 240V AC supply.

The quiet and efficient Dual Machine

With the ability to carry out both wet and dry processes in one unit, our Dual Machines are efficient and quiet in operation. The design integrates two process chambers: an inner chamber that can be used for wet process application, and the outer chamber for dry process applications, both of which make it easier to control.

Dryer Machine Range: The space-saving HT2D Series

The HT2D dryer is perfect for drying small and medium sized components. This space-saving machine can be used as either a batch or a continuous drying machine. Parts are manually inserted into the dryer’s preheated polyurethane lined work chamber and then dried using agro media. The dust free agro product, used in the HT2D, is an excellent moisture absorbent media which also produces a stain free polish effect on components.

Wondering how much you could save with automated finishing?

By using ActOn’s Finishing systems we can guarantee that not only will the parts be finished to a high standard, you’ll also reduce costs and save time.

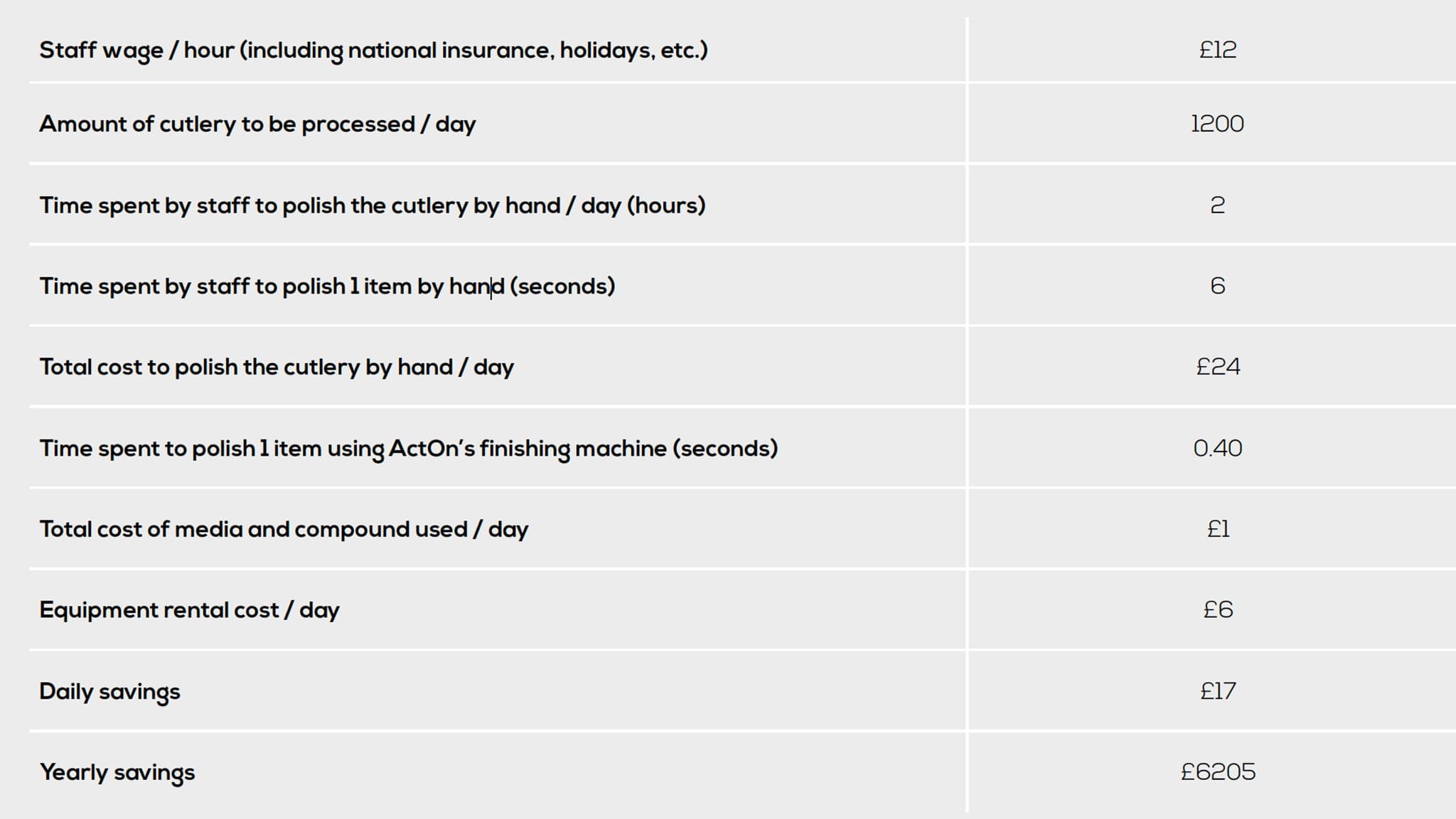

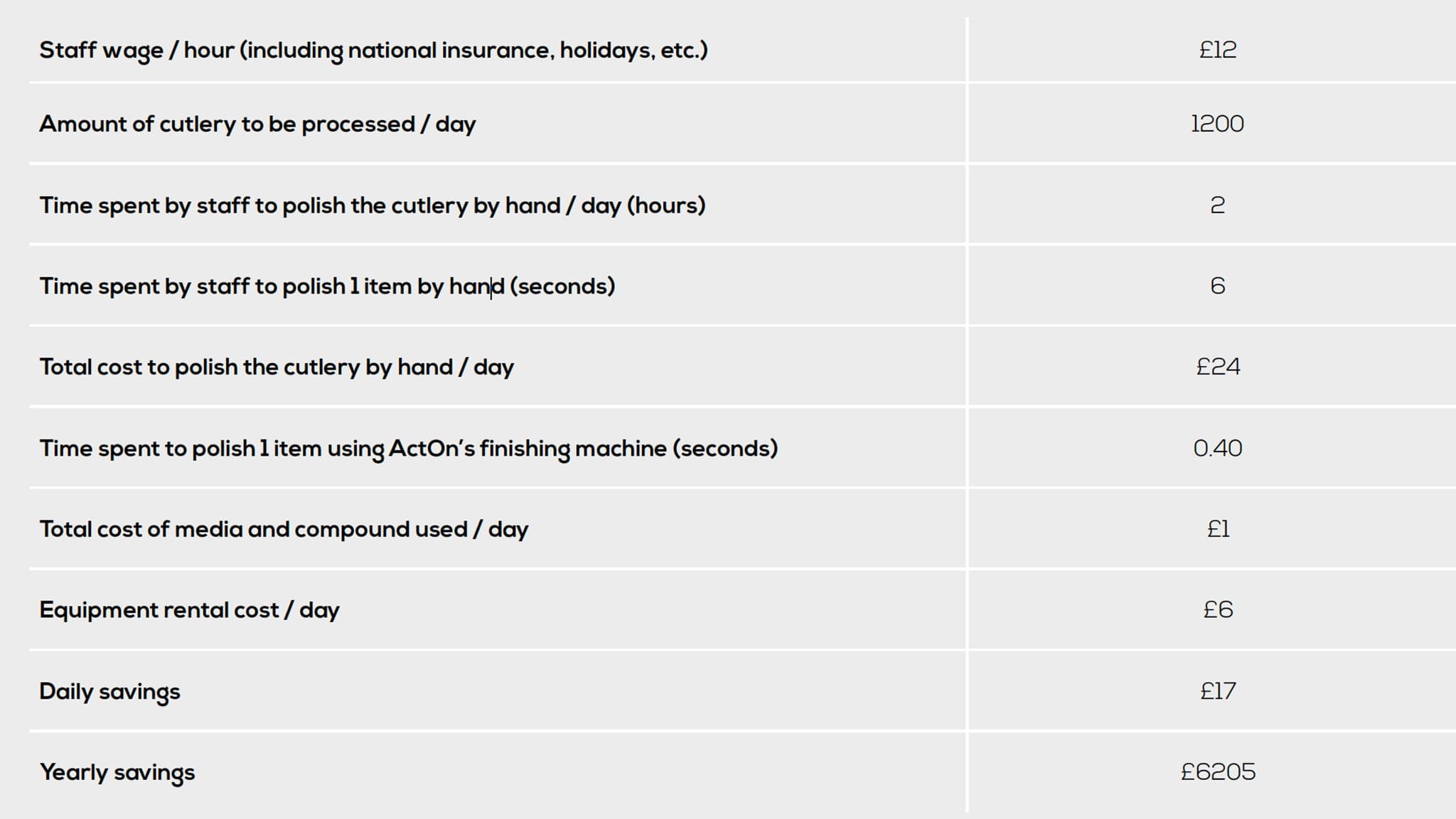

Using our cost calculator we can demonstrate how much you could save per year in the below example, focused on the hospitality industry.

*the above cost calculation applies when using the HT2 machine

In the same time it takes one employee to polish 500 to 600 pieces of cutlery, our HT2 finishing machine can process 3000 to 3500 pieces of cutlery in just one hour.

With ActOn Finishing’s machine, teams are able to use the time they would have spent polishing cutlery on serving tables and taking orders instead – helping you reduce costs on labour and polishing materials.

Are there any alternative affordable finishing options?

At ActOn Finishing, we’re proud to also offer two alternative solutions to purchasing a vibratory machine.

Leasing – perfect for acquiring equipment quickly

Our partnership with Kennet Equipment Leasing, means our customers can acquire new equipment quickly and on terms that best suits their budgets and cash flow.

Leasing is one of the most popular forms of financing equipment today. With terms available from 2-5 years, it’s available for equipment purchases starting from £1000 + VAT. To find out more about the key features on leasing, please visit our dedicated page.

Rental – perfect for keeping up with demand in busy periods

Another alternative affordable finishing option is to rent a machine before purchasing. Renting can provide an effective option during busy periods or while waiting for new equipment to arrive.

Opting to rent a machine helps ensure you find the perfect solution before you buy. With no upfront or hidden costs, ActOn Finishing’s machines are fully maintained and the servicing, parts and labour costs are all included in the rental price. Why not discover more about the benefits of renting?

Find an affordable finishing solution

With a variety of affordable vibratory, dryer and dual machines available at ActOn Finishing, please get in touch with our team of experts who are on hand to answer any questions you may have.