-

-

-

- About

- Industries

-

Sub-Contracting

-

- Consumables

-

Cleaning

-

- All Ultrasonic Machines

- TT Standard Ultrasonic Series

- LT Pro Laboratory Ultrasonic Cleaning Machines

- MOT Automotive Ultrasonic Cleaning Machines

- One Tank Industrial Ultrasonic Cleaning Equipment

- Manual Multistage Ultrasonic Cleaning Equipment

- Multistage Automatic Ultrasonic Cleaning Machine

- Ultrasonic Generators

- Ultrasonic Cleaner Solution

-

-

Blasting & Peening

-

- All Shot Blasting Machines

- Powertrack Junior Portable Blast System

- Powertrack Portable Blast System

- ActOn Mobile Shot Blasting Room

- ECO Shot Blasting Machines

- Premium DI Suction Blasting Machines

- Premium DP Pressure Blasting Cabinets

- AWB Wet Blasting Cabinet

- Premium NP Wet Blasting Cabinets

- Automated Wet Blasting Machine

- NF Sandblasting Cabinets

- DLyte eBlast – Electro Shot Blaster

- AM Shot Peening and Blasting Series

- Automated Shot Blasting Equipment

- All Wheel Blasting Machines

- Spinner Hanger Blast Machine

- Tumble Rubber Belt Shot Blasting Machine

- Tumble Steel Belt Shot Blasting Machine

- Wire Mesh Belt Shot Blasting Machine

- Continuous Feed Overhead Rail Blasting Machine

- Roller Conveyor Blast Machine

- Continuous Feed Tube & Bar Blast Cleaning Machine

- Rotary Table Shot Blasting Machine

- Tunnel Concrete Shot Blast Machine

-

-

Surface Finishing

-

-

Surface Finishing

- All Mass Finishing Machines

- Vibratory Bowl Machines

- Vibratory Trough Machines

- Dual Finishing Machines

- Dryers

- Centrifugal High Energy Machines

- Disc Finishing Machines

- LE30 Rotary Barrel Machine

- Wheel Polishing Machine

- Automation for Mass Finishing

- Mass Finishing Accessories

- All Vibratory Machines

- Vibratory Dual Machines

- Vibratory Consumables

- Vibratory Bowl Machines

- Vibratory Trough Machines

- Dlyte Technology

- Waste Water Treatment

- REFURBISHED MACHINES

-

Blasting & Peening

- All Shot Blasting Machines

- Powertrack Junior Portable Blast System

- Powertrack Portable Blast System

- ActOn Mobile Shot Blasting Room

- ECO Shot Blasting Machines

- Premium DI Suction Blasting Machines

- Premium DP Pressure Blasting Cabinets

- AWB Wet Blasting Cabinet

- Premium NP Wet Blasting Cabinets

- Automated Wet Blasting Machine

- NF Sandblasting Cabinets

- DLyte eBlast – Electro Shot Blaster

- AM Shot Peening and Blasting Series

- Automated Shot Blasting Equipment

- All Wheel Blasting Machines

- Spinner Hanger Blast Machine

- Tumble Rubber Belt Shot Blasting Machine

- Tumble Steel Belt Shot Blasting Machine

- Wire Mesh Belt Shot Blasting Machine

- Continuous Feed Overhead Rail Blasting Machine

- Roller Conveyor Blast Machine

- Continuous Feed Tube & Bar Blast Cleaning Machine

- Rotary Table Shot Blasting Machine

- Tunnel Concrete Shot Blast Machine

- Refurbished Machines

-

Cleaning

- All Ultrasonic Machines

- TT Standard Ultrasonic Series

- LT Pro Laboratory Ultrasonic Cleaning Machines

- MOT Automotive Ultrasonic Cleaning Machines

- One Tank Industrial Ultrasonic Cleaning Equipment

- Manual Multistage Ultrasonic Cleaning Equipment

- Multistage Automatic Ultrasonic Cleaning Machine

- Ultrasonic Generators

- Ultrasonic Cleaner Solution

- Vibratory Finishing Machines

- Consumables

- Sub-Contracting

- Industries

- About

- Free Trial

- Contact us

Mass Finishing Machines

Using quality mass finishing vibratory machinery, media and compounds, we indulge in process development that is unparalleled. Our engineers have worked tirelessly over the years to provide you with quality and cost-effective finishing solutions. The developments have been in all areas, from the Vibratory and High Energy finishing technology to mass finishing consumables, to optimise in accordance to your needs.

I WANT A FREE TRIAL

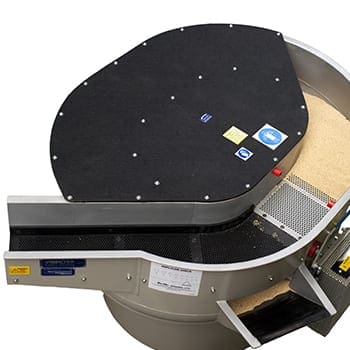

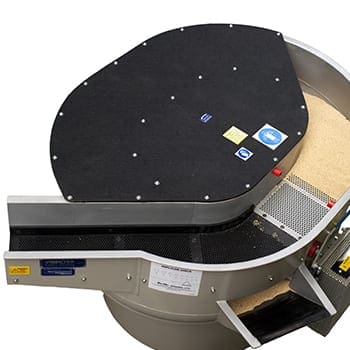

Vibratory Bowl

Each of our Bowl surface finishing machines are simple to operate and highly efficient, manufactured in classic designs and sizes to meet your unique applications.

Get a Quote

Explore more

Vibratory Troughs

We offer Troughs in many different sizes and an infinite choice of length and width combinations, making them one of our most versatile. These are particularly useful for larger components.

Get a Quote

Explore more

Dual Finishing Machine

The orbital Dual surface finishing machine works to both deburr and dry in one single unit. This is both an excellent and economical finishing option.

Get a Quote

Explore more

Dryers

Our unique, elliptical-shaped Vibratory bowl drying machines are compact in size, and simple to operate. The design provides the flexibility to use it as an effective 1 lap drying process or a multi lap process. We also offer conveyorised ovens and rotary dryers.

Get a Quote

Explore more

Centrifugal High Energy Machine

Engineered with the latest technology, the drive mechanism is designed to produce high g-forces resulting in shorter process times. This technology can be used for both wet and dry processes.

Get a Quote

Explore more

Centrifugal Disc Finishing Machine

The centrifugal disc finishing machines are perfect for processing small to medium batches of parts in a reduced period of time.

Get a Quote

Explore more

Wheel Polishing Machine

Suitable for achieving a highly polished finish on wheels, the AWP188 machine has been designed to be simple to operate and to produce excellent results.

Get a Quote

Explore more

LE30 Rotary Barrel Machine

Designed as an economic yet efficient finishing machine, for applications such as deburring, cleaning, descaling, polishing, removal of rust or smooth finishing.

Get a Quote

Explore more

Waste Water Treatment

Our customers trust us to help select a waste water treatment system that complies with the industry’s growing regulations. Once processed, the effluent is treated in the ActOn centrifuge system before being discharged to the drain or recycled.

Get a Quote

Explore more

Automation for Mass Finishing

Both the Vibratory and High Energy can be automised to reduce manual handling, and to ensure a consistent process. Our automated systems are operator friendly, and can be custom built to suit your needs.

Get a Quote

Explore more

Accessories for Mass Finishing

Each of our accessories is simple to operate, highly efficient and has been designed to complement ActOn’s vibratory and centrifugal high energy finishing machines.

Get a Quote

Explore more