Surface finishing is one of the key elements of any production process for manufactured parts. The mass finishing process has the potential to take manufactured goods to the next level in terms of quality, durability, and appearance.

Whether you’re a business owner or an engineer, you know how important it is to provide polished, long-lasting products to your customers, which is exactly what a good quality mass finishing machine can achieve.

To help you understand the mass finishing process, how long it should take, and how many parts can be processed at once, we’ve broken down everything you need to know:

How long should my mass finishing process take?

Determining how long your mass finishing process should take can be challenging to gauge as it’s dependent on several factors;

- Part material

- The initial condition of the part

- Condition of the consumables

- Quality of the finishing machine

However, the easiest way to find out is through carrying out finishing trials. This will enable you to test, improve and ascertain the mass finishing process parameters and establish a repeatable solution.

During the finishing trials, you should consider having a number of part samples to use for testing. Ensure these samples are the exact replica of the component to be finished, to certify that the solution is viable.

Once you have carried out the finishing trial, we recommend recording every stage in a trial report. This will be helpful as you may need to carry out more than one trial and will be especially beneficial when you review and improve the final mass finishing process.

Once you are happy with the final vibratory finishing process we recommend making a data card. This should contain process parameters, inspection criteria, and any other notes to ensure repeatability in results.

At ActOn Finishing, we conduct a free trial and arrange consulting meetings with our customers in order to achieve optimal and repeatable results.

How many parts can I finish at once?

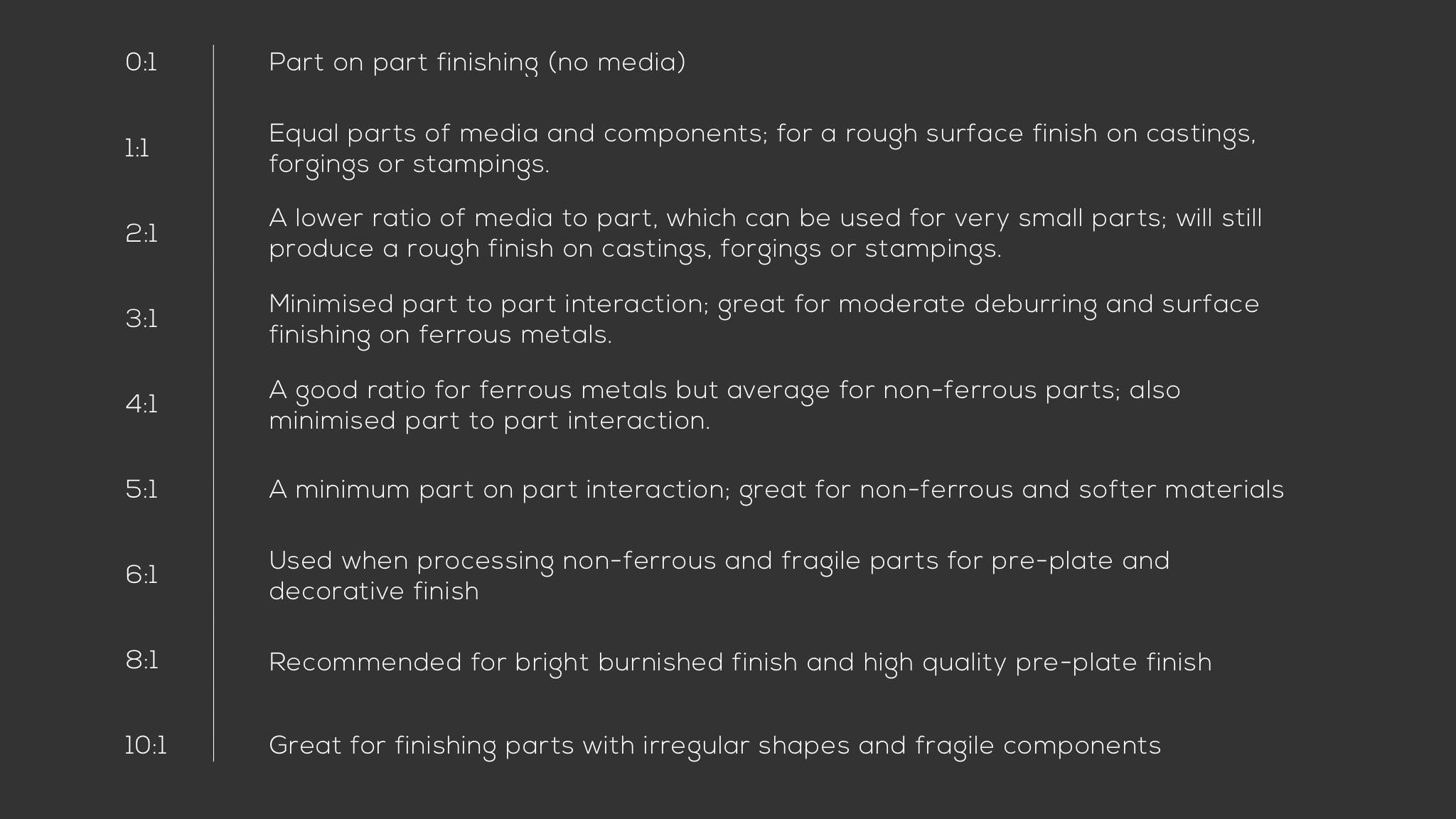

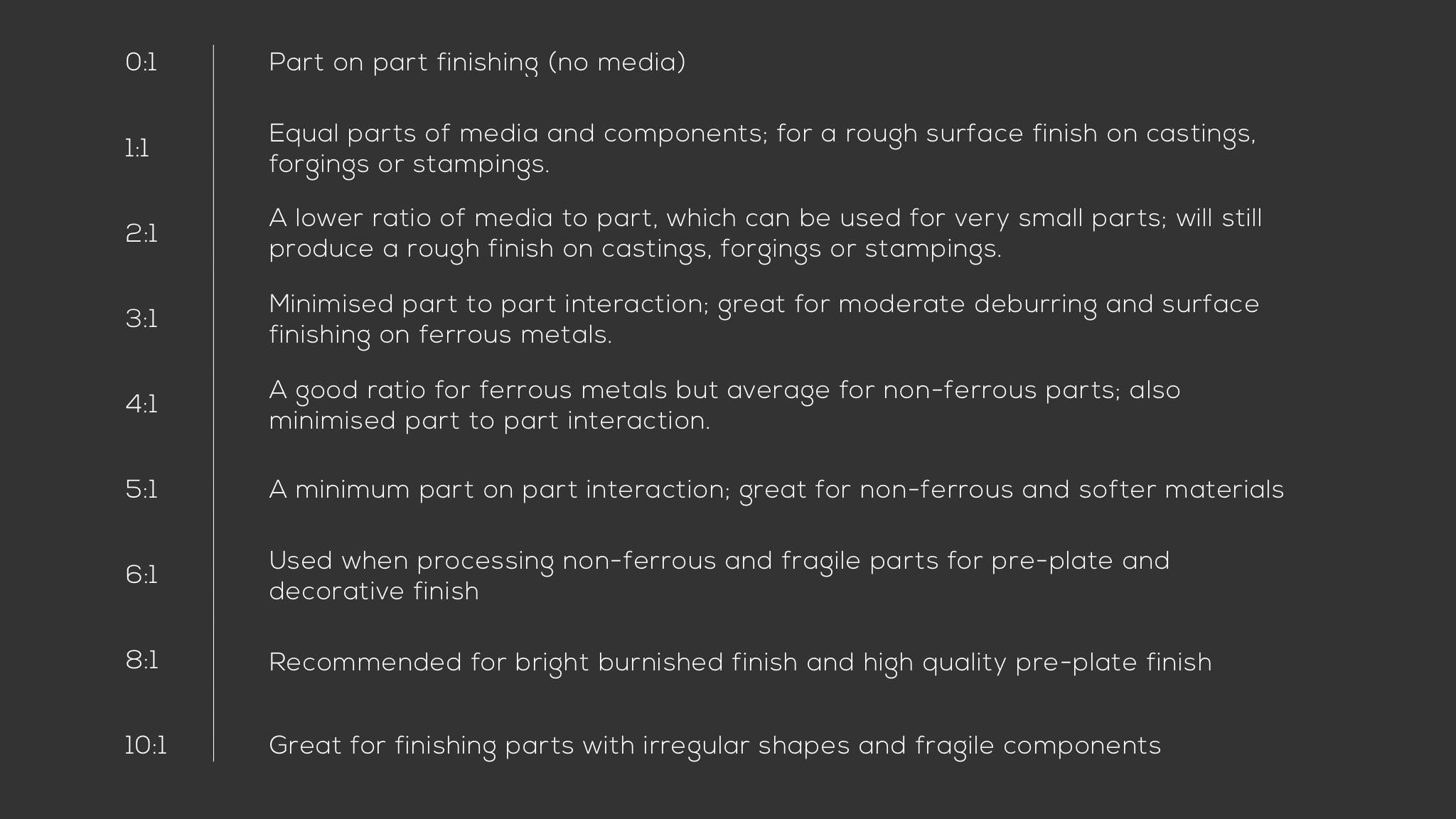

During the mass finishing process, the amount of parts to be processed per batch, also known as the workload, can be determined through media to part ratio. To establish what this is, you need to calculate the part volume and know the usable volume of the finishing machine work chamber (approx. 90% for vibratory machine).

The guidelines below will help you in determining the right media to part ratio for your process:

For precision or delicate components, it’s advisable to finish these individually in work chambers, sub-divided using divider plates to avoid part on part interaction.

Trial your mass finishing process

At ActOn Finishing, we customise our mass finishing products and services to meet your specific parts and finishing requirements. Arrange your free trial or book in a consultation and let us help you achieve optimal results. Our trials enable us to select the best finishing machine, media, and compound for achieving your desired finish.