Do you need to understand the Mass Finishing process and how it can benefit your business? At ActOn Finishing, we believe that sharing our knowledge with our customers can help you better understand what we do, and how we can add value to your operations.

We’ve taken the 8 most asked questions relating to Mass Finishing, to tell you exactly what you need to know, including how to incorporate Mass Finishing into your operations and how to use Mass Finishing to obtain optimum results.

1. What is Mass Finishing?

Mass Finishing is a process that automates the mechanical and chemical finishing of various shaped parts, allowing large numbers of parts to be finished simultaneously.

2. How does it work?

Mass Finishing works by placing a combination of media, parts and compound into a finishing machine. The vibrations cause the contents to move in a circular motion and media to grind against the part to achieve the desired finish. This process can be wet or dry, and can run with or without media.

3. What can I achieve through Mass Finishing?

Mass finishing techniques are usually implemented in the manufacturing processes for economic advantages and the consistent results achieved. Our Mass Finishing solutions also improve these current processes, achieving the repeatability and quality desired by manufacturers.

Achieved outcomes vary, based on the type of application. Our comprehensive list includes:

- Deburring

- Descaling

- Removing heat treat scale, coatings, grease and oil

- Cutting down / blending of cast / forged surfaces and split lines

- Radiusing

- Removing cutting /machine lines / tool marks

- Removal of surface defects

- Cleaning and degreasing

- Smoothing

- Polishing

- Brightening

- Mirror Finishing

- Drying

- Corrosion Protection

- Surface Finishing

4. What finishing process can’t be achieved?

There are a few exceptions to what can be done when it comes to the Mass Finishing process. These are:

- Small internal bores/blind holes cannot be deburred or polished

- Material removed from selective areas (unless protected by mask)

- Heavy burr removal (parent material) – this would be rounded only

5. What type of Mass Finishing process can I use?

We have four Mass Finishing processes, depending on your desired outcome:

- Continuous Systems – parts enter at one end and are continually discharged at the exit in the finished stage

- Batch Systems – parts are processed by batch. Once one batch is processed, it is removed and the next batch is run

- Sequenced Systems – running parts through multiple processes to produce the desired finish

- Single part systems – large parts are processed individually

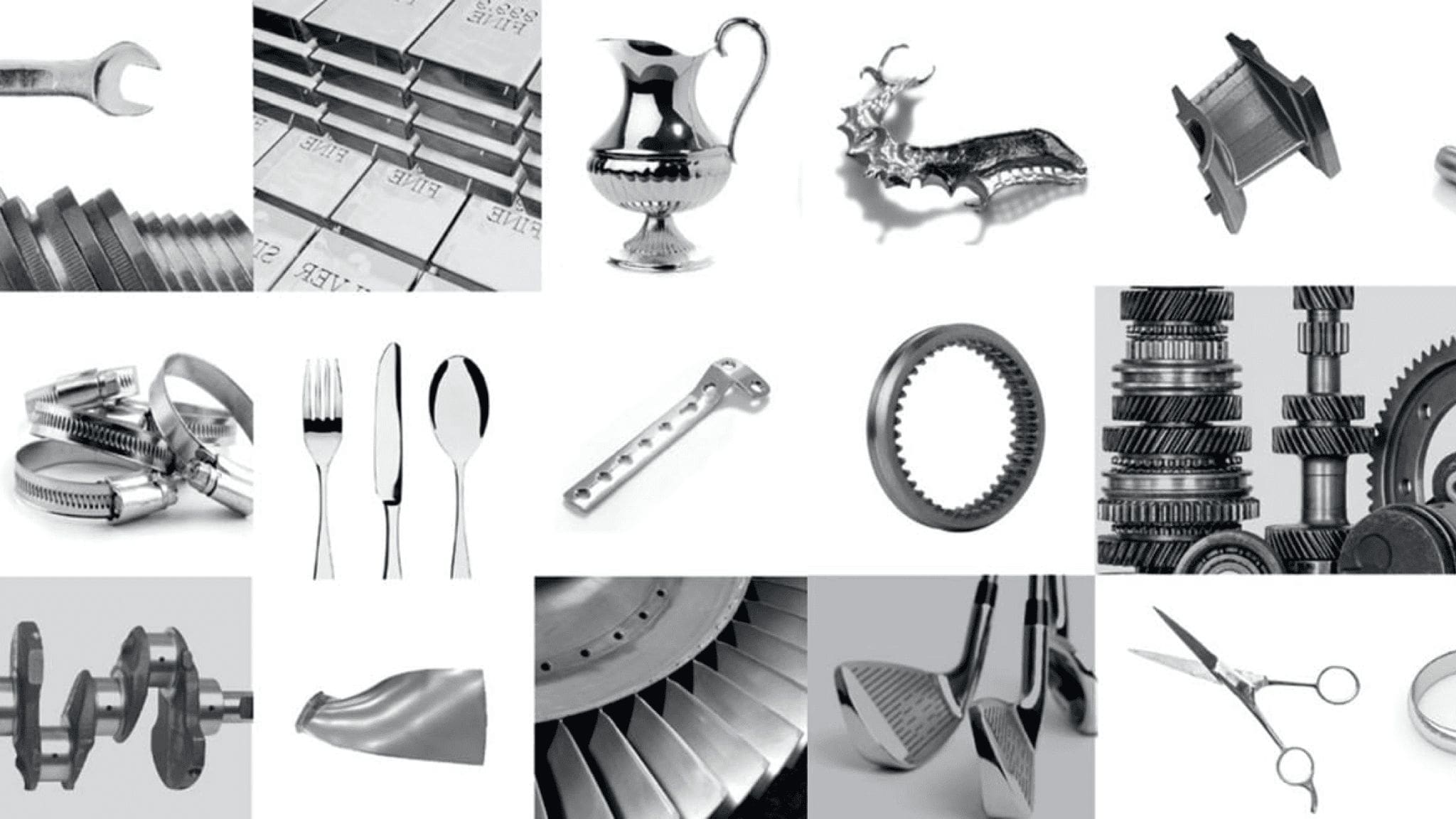

6. Can I finish any component?

Our Mass Finishing technology is extremely versatile, which means you can process components:

- Of any size and shape

- Made of ferrous materials such as carbon steel, hardened steel, iron and stainless steel

- Made of non-ferrous materials such as aluminium, brass, ceramic, magnesium, plastic, titanium and zinc

We have also developed finishing solutions that apply to various industries such as Aerospace, Additive Manufacturing, Automotive, Coin Blanking, Fashion, Forgings and Castings, General Engineering, Hospitality, Manufacturing and Medical.

7. What technology do I need to finish my parts?

To achieve the required surface finish, it is important to use the correct finishing machinery, media and compound.

Finishing machine:

Media:

- Ceramic and Plastic Media

- Agro and Pre-treated Media

- Special Media

Compound:

- Liquid Compound

- Powders and Pastes

- Special Compounds

8. What are the advantages of using Mass Finishing?

There are many advantages to using Mass Finishing process:

- Reduced processing times in comparison with manual finishing

- Lower cost per part

- Producing repeatable and quality finish on all products

- Environmentally friendly

- Finishing solutions can be customised to suit user applications

- Parts of any shape, size and material can be mass finished

We hope our blog has given you a better understanding of the Mass Finishing process and, if you would like to learn more about Mass Finishing technology and the solutions we offer, our friendly team is on hand to answer all your questions. Just call +44 (0) 24 7646 6914 or take a further look at our website.

We look forward to hearing from you.