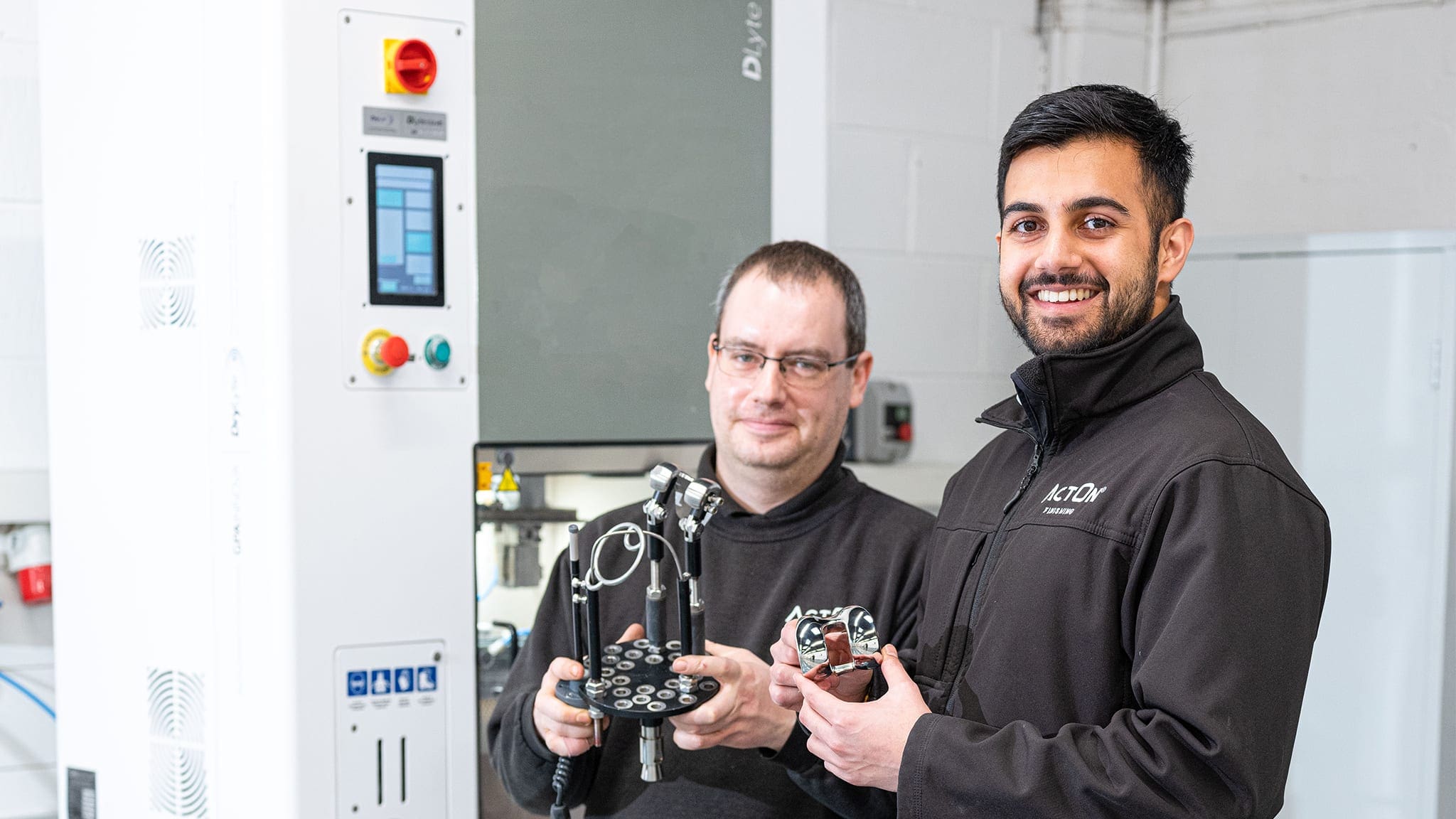

ActOn Finishing Offers Mirror Finishing Solution to UK Manufacturing Market by Acquiring the DLyte PRO500

The DLyte PRO500, manufactured by GPAINNOVA, offers exceptional metal surface finishing results with superior speed and efficiency replacing manual finishing. ActOn can now supply this machine or offer a subcontract finishing service. Sid Gulati, Managing Director at ActOn Finishing, states: “We are very pleased with our latest addition to our test lab. We currently manufacture… Read more »

Read more