Tumble finishing vs Vibratory finishing: Are you using the right method?

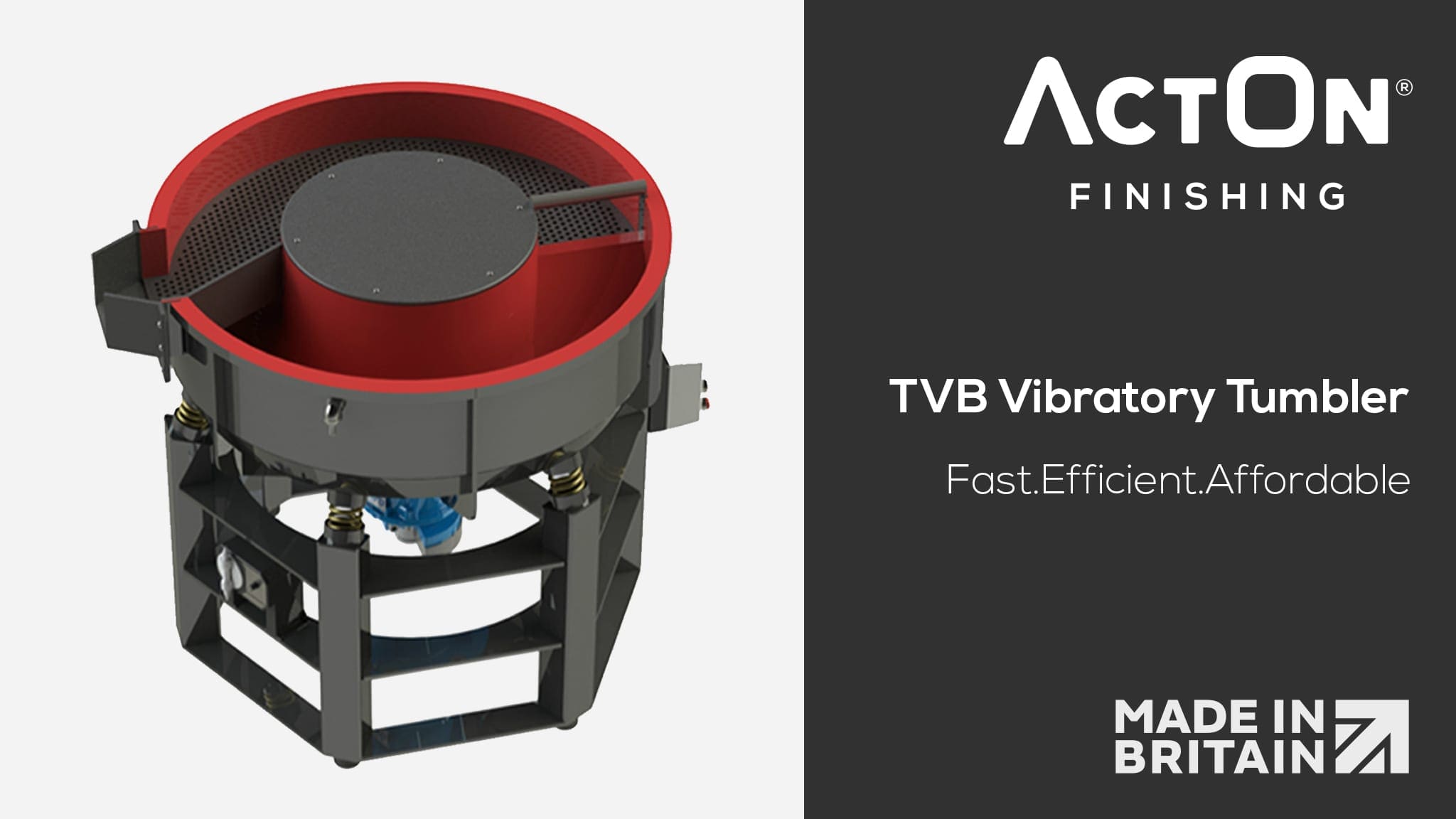

Mass finishing offers the ability to cost-effectively finish large quantities of parts at one time. The most common types of mass finishing are tumble finishing and vibratory finishing for applications such as deburring, cleaning, radiusing, de-flashing, descaling, polishing, dust removing or surface smoothing. In this article we are going to unpack what these are and… Read more »

Read more