-

-

-

- About

- Industries

-

Sub-Contracting

-

- Consumables

-

Cleaning

-

- All Ultrasonic Machines

- TT Standard Ultrasonic Series

- LT Pro Laboratory Ultrasonic Cleaning Machines

- MOT Automotive Ultrasonic Cleaning Machines

- One Tank Industrial Ultrasonic Cleaning Equipment

- Manual Multistage Ultrasonic Cleaning Equipment

- Multistage Automatic Ultrasonic Cleaning Machine

- Ultrasonic Generators

- Ultrasonic Cleaner Solution

-

-

Blasting & Peening

-

- All Shot Blasting Machines

- Powertrack Junior Portable Blast System

- Powertrack Portable Blast System

- ActOn Mobile Shot Blasting Room

- ECO Shot Blasting Machines

- Premium DI Suction Blasting Machines

- Premium DP Pressure Blasting Cabinets

- AWB Wet Blasting Cabinet

- Premium NP Wet Blasting Cabinets

- Automated Wet Blasting Machine

- NF Sandblasting Cabinets

- DLyte eBlast – Electro Shot Blaster

- AM Shot Peening and Blasting Series

- Automated Shot Blasting Equipment

- All Wheel Blasting Machines

- Spinner Hanger Blast Machine

- Tumble Rubber Belt Shot Blasting Machine

- Tumble Steel Belt Shot Blasting Machine

- Wire Mesh Belt Shot Blasting Machine

- Continuous Feed Overhead Rail Blasting Machine

- Roller Conveyor Blast Machine

- Continuous Feed Tube & Bar Blast Cleaning Machine

- Rotary Table Shot Blasting Machine

- Tunnel Concrete Shot Blast Machine

-

-

Surface Finishing

-

-

Surface Finishing

- All Mass Finishing Machines

- Vibratory Bowl Machines

- Vibratory Trough Machines

- Dual Finishing Machines

- Dryers

- Centrifugal High Energy Machines

- Disc Finishing Machines

- LE30 Rotary Barrel Machine

- Wheel Polishing Machine

- Automation for Mass Finishing

- Mass Finishing Accessories

- All Vibratory Machines

- Vibratory Dual Machines

- Vibratory Consumables

- Vibratory Bowl Machines

- Vibratory Trough Machines

- Dlyte Technology

- Waste Water Treatment

- REFURBISHED MACHINES

-

Blasting & Peening

- All Shot Blasting Machines

- Powertrack Junior Portable Blast System

- Powertrack Portable Blast System

- ActOn Mobile Shot Blasting Room

- ECO Shot Blasting Machines

- Premium DI Suction Blasting Machines

- Premium DP Pressure Blasting Cabinets

- AWB Wet Blasting Cabinet

- Premium NP Wet Blasting Cabinets

- Automated Wet Blasting Machine

- NF Sandblasting Cabinets

- DLyte eBlast – Electro Shot Blaster

- AM Shot Peening and Blasting Series

- Automated Shot Blasting Equipment

- All Wheel Blasting Machines

- Spinner Hanger Blast Machine

- Tumble Rubber Belt Shot Blasting Machine

- Tumble Steel Belt Shot Blasting Machine

- Wire Mesh Belt Shot Blasting Machine

- Continuous Feed Overhead Rail Blasting Machine

- Roller Conveyor Blast Machine

- Continuous Feed Tube & Bar Blast Cleaning Machine

- Rotary Table Shot Blasting Machine

- Tunnel Concrete Shot Blast Machine

- Refurbished Machines

-

Cleaning

- All Ultrasonic Machines

- TT Standard Ultrasonic Series

- LT Pro Laboratory Ultrasonic Cleaning Machines

- MOT Automotive Ultrasonic Cleaning Machines

- One Tank Industrial Ultrasonic Cleaning Equipment

- Manual Multistage Ultrasonic Cleaning Equipment

- Multistage Automatic Ultrasonic Cleaning Machine

- Ultrasonic Generators

- Ultrasonic Cleaner Solution

- Vibratory Finishing Machines

- Consumables

- Sub-Contracting

- Industries

- About

- Free Trial

- Contact us

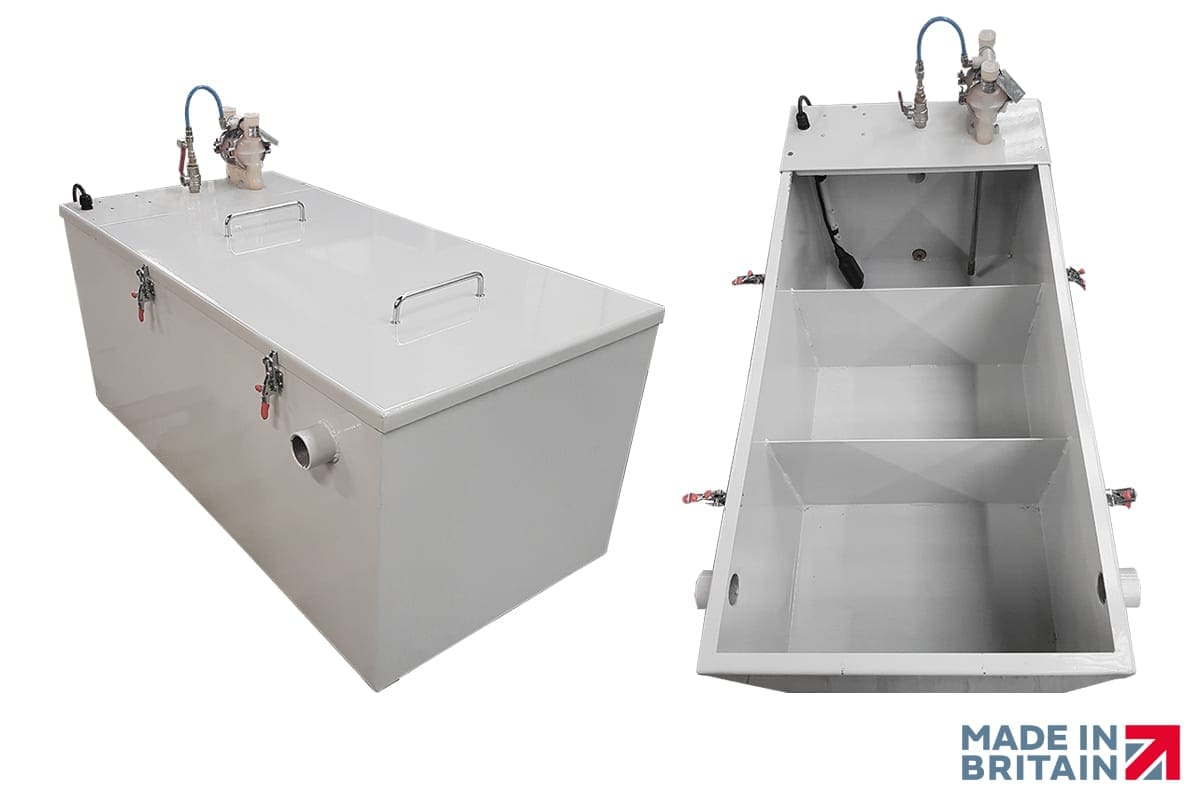

Waste Water Treatment Solutions

The process of wet mass finishing generates a discharge of the processing liquid, which comprises of the metal fines, abrasives, compound and in some instances, oil due to the condition of the parts. ActOn suggests having a suitable waste water solution in place as a responsible measure towards the environment and also to facilitate recycling in certain applications and reduce processing costs. However, there may be cases when recycling of processed water is not possible.

For both cases ActOn Finishing has developed waste water solution treatment products such as the Batch and Automatic Centrifuge, Recirculation Tanks, Settlement Tanks With or Without Pumps and Consumables for Effluent Treatment.

Finishing cost calculatorKey Feature

- Durable water treatment systems due to design, good quality materials and workmanship knowledge.

- ActOn batch centrifuge has been designed in a way to allow 3 x 280L finishing machines to be connected.

- Recirculation tanks and Settlement tanks available for processing small quantities of effluent.

- Easy to access chambers for cleaning the sludge.

- User friendly control system with/without PLC controls.

- Lifting stations can also be used to pump effluent from the finishing machines into the batch centrifuge.

- Auto functionality with minimum supervision required.

Key Benefits

- The treated effluent can be recirculated or discharged straight to drain.

- Reduced water and compounds consumption (greater than 90%).

- Environmentally friendly effluent treatment solutions.

- Cost-effective.

- User friendly.

- Low maintenance.

- Tailored treatment solutions to meet customer’s requirements.

Technical Specifications

For further technical specifications on our Waste Water Treatment range, please download our brochure.

If you would like to receive a Free Trial, please complete the below form to help us determine the optimum effluent treatment solution for your process. After completing the request form, post your sample effluent along with the completed form to: ActOn Finishing Limited, 213 Torrington Avenue, Tile Hill, Coventry, CV4 9HN, United Kingdom

DOWNLOAD BROCHUREDOWNLOAD FREE TRIAL FORM

Case Study

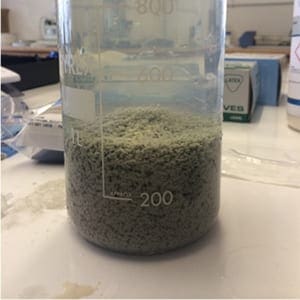

Zinc & Copper Water Treatment Solution

Start condition of the discharge liquid post process:

- Zn: 120 mg/l

- Cu: 1000 mg/

Required results post-treatment:

- Zn: 7.5 mg/l

- Cu: 5.0 mg/l

Post-treatment results using the ActOn Water Treatment Solutions:

- Zn: 0.43 mg/l

- Cu: 0.38 mg/l